Large Size Platinum or Platinum-Rhodium Crucible Holder Assemblies

A clamping component and large-size technology, which is applied in the mechanical field, can solve the problems such as difficulty in ensuring the assembly accuracy of platinum crucibles, and achieve the effect of reducing welding errors, reducing assembly error rates, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

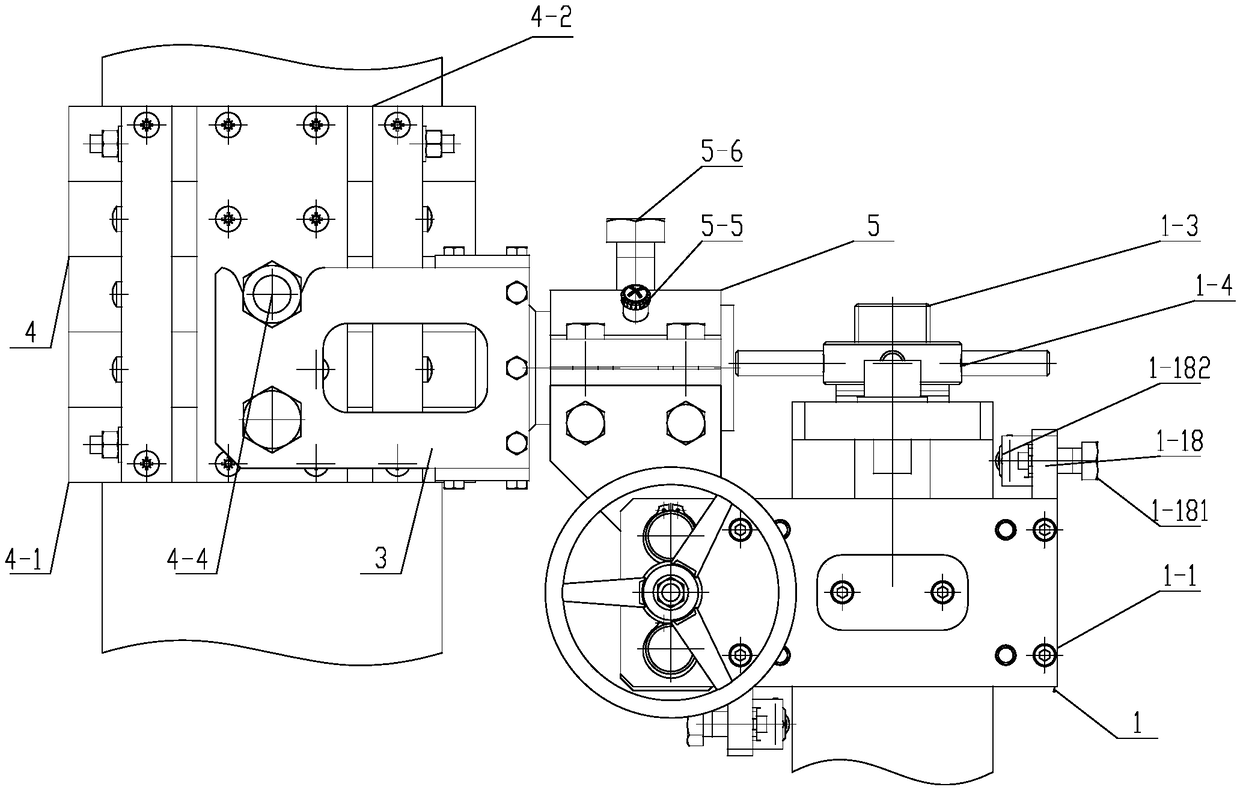

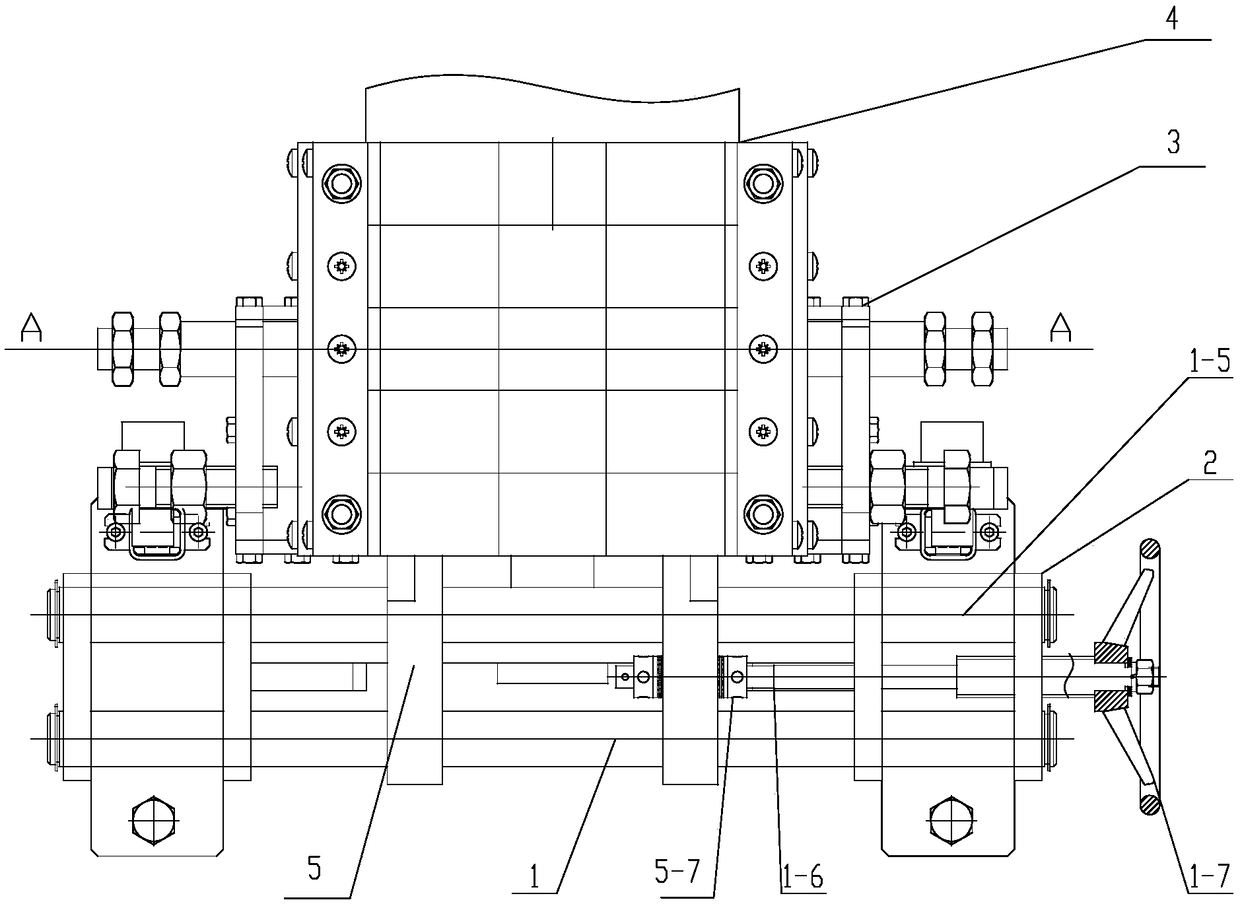

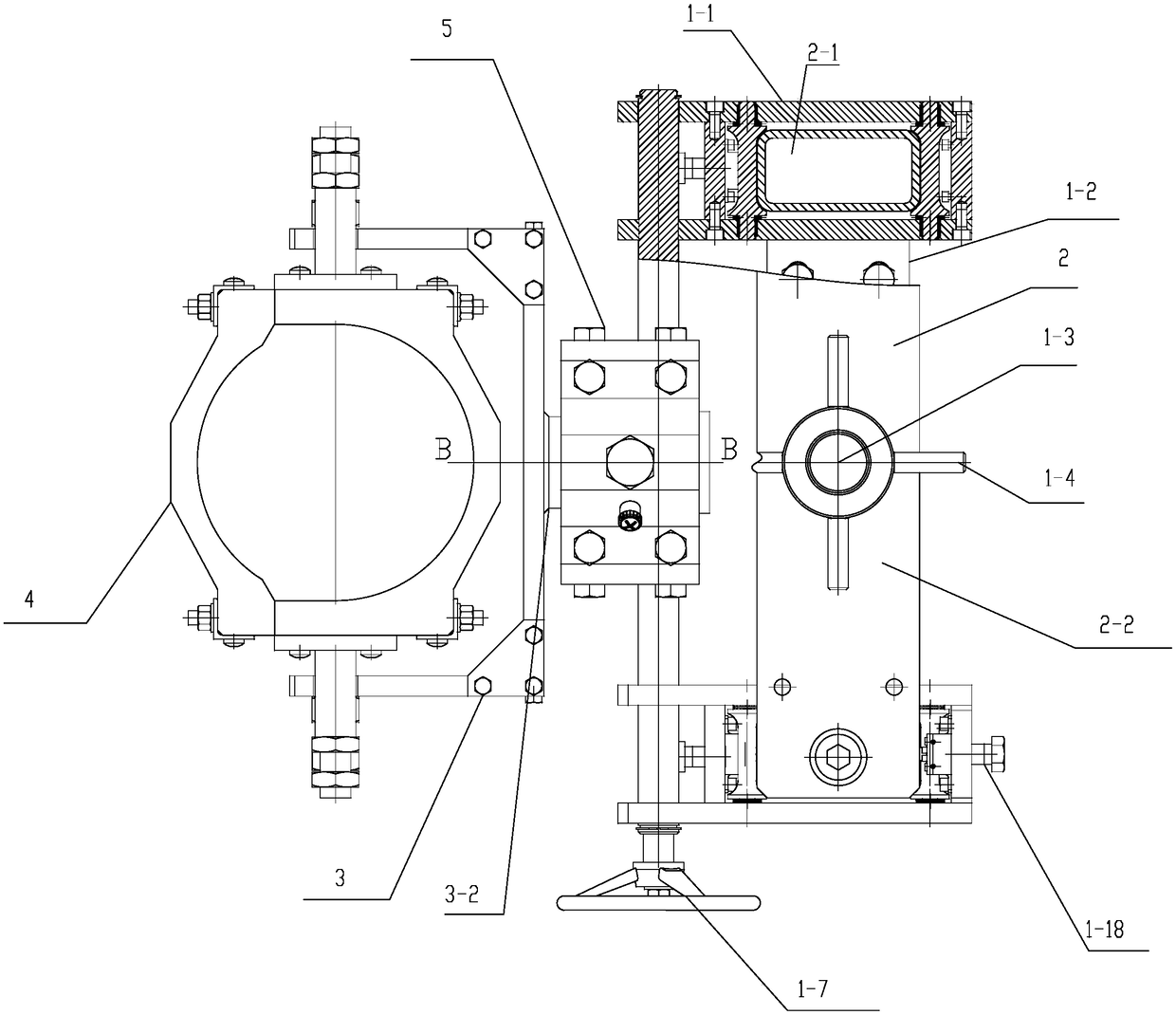

[0034] As shown in the figure: a large-size platinum or platinum-rhodium crucible clamping assembly, including a vertical movement mechanism 1, a positioning mechanism 2, a crucible support 3, a clamping assembly 4 and a crucible support component 5; the vertical movement mechanism 1 and the positioning mechanism 2 Connection; the clamping assembly 4 is connected with the crucible support 3 , the crucible support 3 is connected with the crucible support part 5 , and the support part 5 is connected with the vertical movement mechanism 1 .

[0035] The vertical movement mechanism 1 includes two side fixed frames 1-1, a connecting plate 1-2, a round nut 1-3, a nut rotating rod 1-4, a support shaft 1-5, a stepped shaft 1-6 and a hand wheel 1-7; the two side fixed frames 1-1 are connected by a connecting plate 1-2, and two support shafts 1-5 are also arranged between the two side fixed frames 1-1; the ladder Shaft 1-6 is connected to one of the side fixed frames 1-1, hand wheel 1-7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com