Pilot-operated electromagnetic directional valve

An electromagnetic reversing valve and pilot-operated technology, applied in valve details, multi-way valves, valve devices, etc., can solve problems such as easy scratches on screws, facilitate disassembly and maintenance, enhance sealing reliability, and improve assembly pass rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

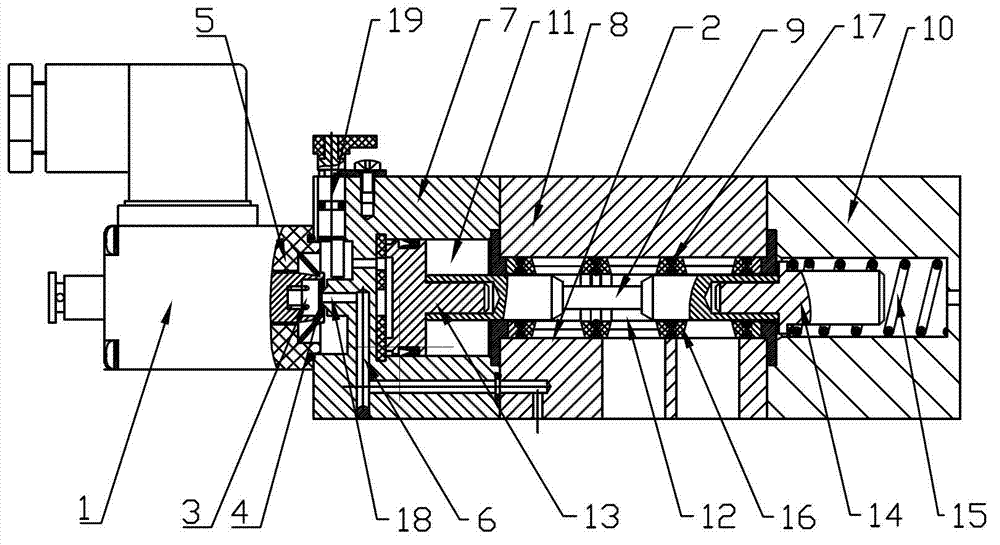

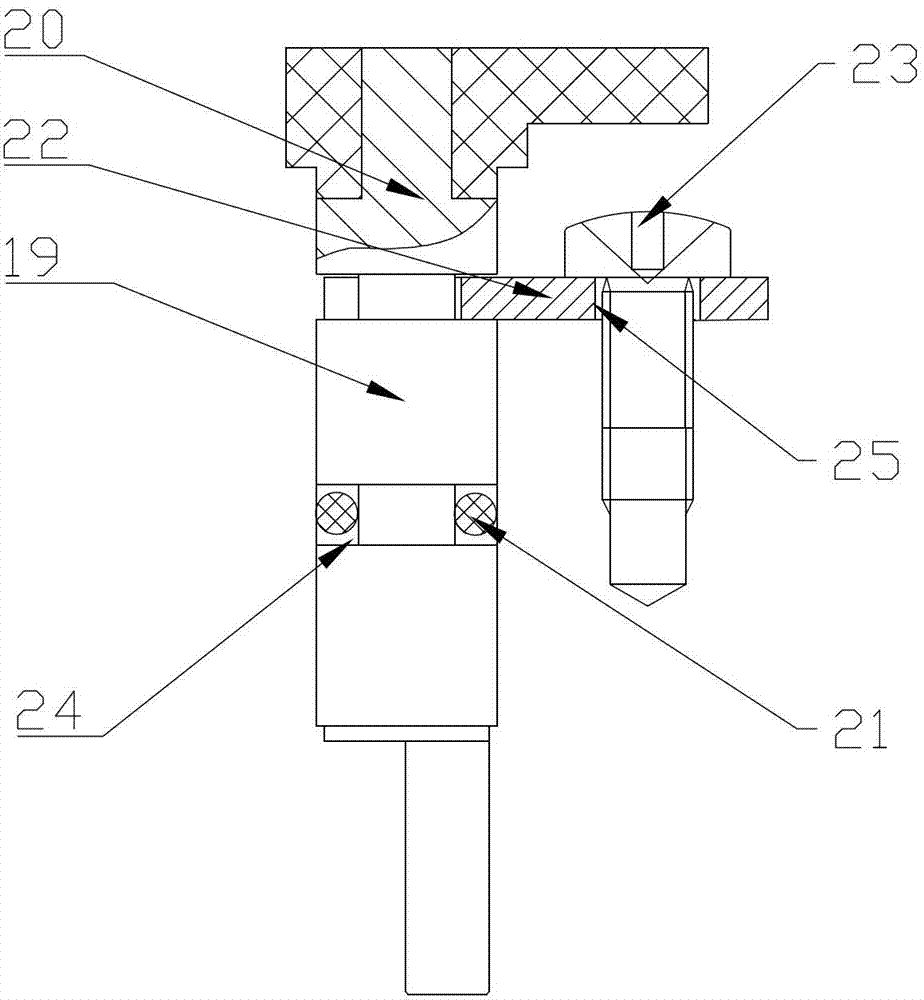

[0013] Such as Figure 1-2 As shown, the pilot electromagnetic reversing valve of the present invention includes an electromagnetic pilot valve 1, an air path control main valve 2 and a manual adjustment rod assembly 19, and the air path control main valve 2 includes a control end cover 7, a valve body 8 and The reset end cover 10, the control end cover 7, the valve body 8 and the reset end cover 10 are connected in sequence, the other end of the control end cover 7 is connected with the electromagnetic pilot valve 1, and the manual adjustment rod assembly 19 is set On the control end cover 7, the manual adjustment rod assembly 19 includes a manual adjustment rod 20, an "O" ring 21, a positioning plate 11, and a positioning screw 23, and the manual adjustment rod 20 extends into the part inside the control end cover 7 An annular groove 24 is provided, and the "O" ring 21 is placed in the annular groove 24. The end of the manual adjustment rod 20 protruding from the control end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com