Air cylinder with end cover sealing structure

An end cap sealing and cylinder technology, which is applied in the direction of engine sealing, fluid pressure actuating device, engine components, etc., can solve the problems of poor sealing performance, air leakage on the cylinder end face, and difficulty in controlling the tightening force of tie rods, so as to reduce the difficulty of assembly. , The effect of enhancing sealing reliability, improving assembly qualification rate and efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

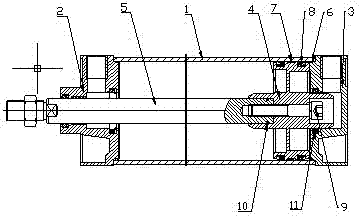

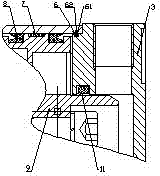

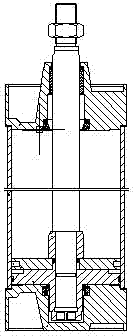

[0019] Such as figure 1 Shown, the present invention has a kind of cylinder with end cover sealing structure, and it comprises cylinder body 1, front end cover 2, rear end cover 3, piston 4 and piston rod 5, described front end cover 2 and rear end cover 3 and cylinder body 1 are connected by tie rods, the piston 4 and the piston rod 5 are both arranged in the cylinder body 1, one end of the piston rod 5 is connected to the piston 4, and the other end extends out of the front end cover 2, and the front end cover 2 and the rear end Sealing grooves 61 are provided on the convex parts where the cover 3 and the cylinder body 1 are combined, and sealing rings 62 are arranged in the sealing grooves 61, and the sealing rings 62 arranged in the sealing grooves 61 are O-rings. . The sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com