Automatic inserting equipment for U-shaped tubes

A U-shaped tube and automatic technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low efficiency, different evaluation standards, manual detection efficiency, low accuracy, etc., to improve the assembly pass rate, Likelihood-Reducing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

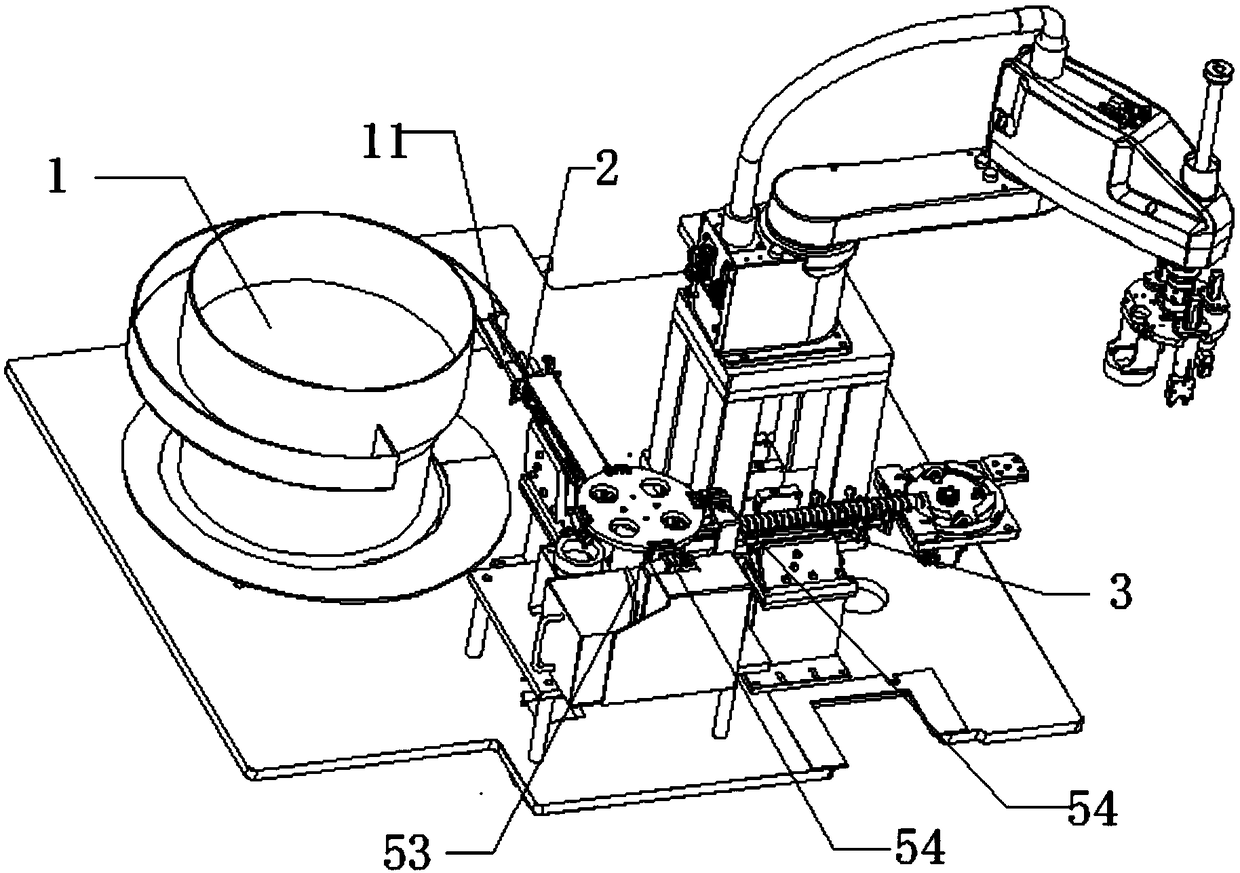

[0050] An automatic insertion device for U-shaped tubes, which sequentially includes: a vibration plate 1 (prior art), a first vibration transmission plate 2, a detection component, a third vibration transmission plate 3, Distribution components, capture components;

[0051] The outlet 11 of the vibration plate 1 is connected to the inlet end of the first vibration transmission plate 2, and a detection component is installed behind the outlet end of the first vibration transmission plate 2;

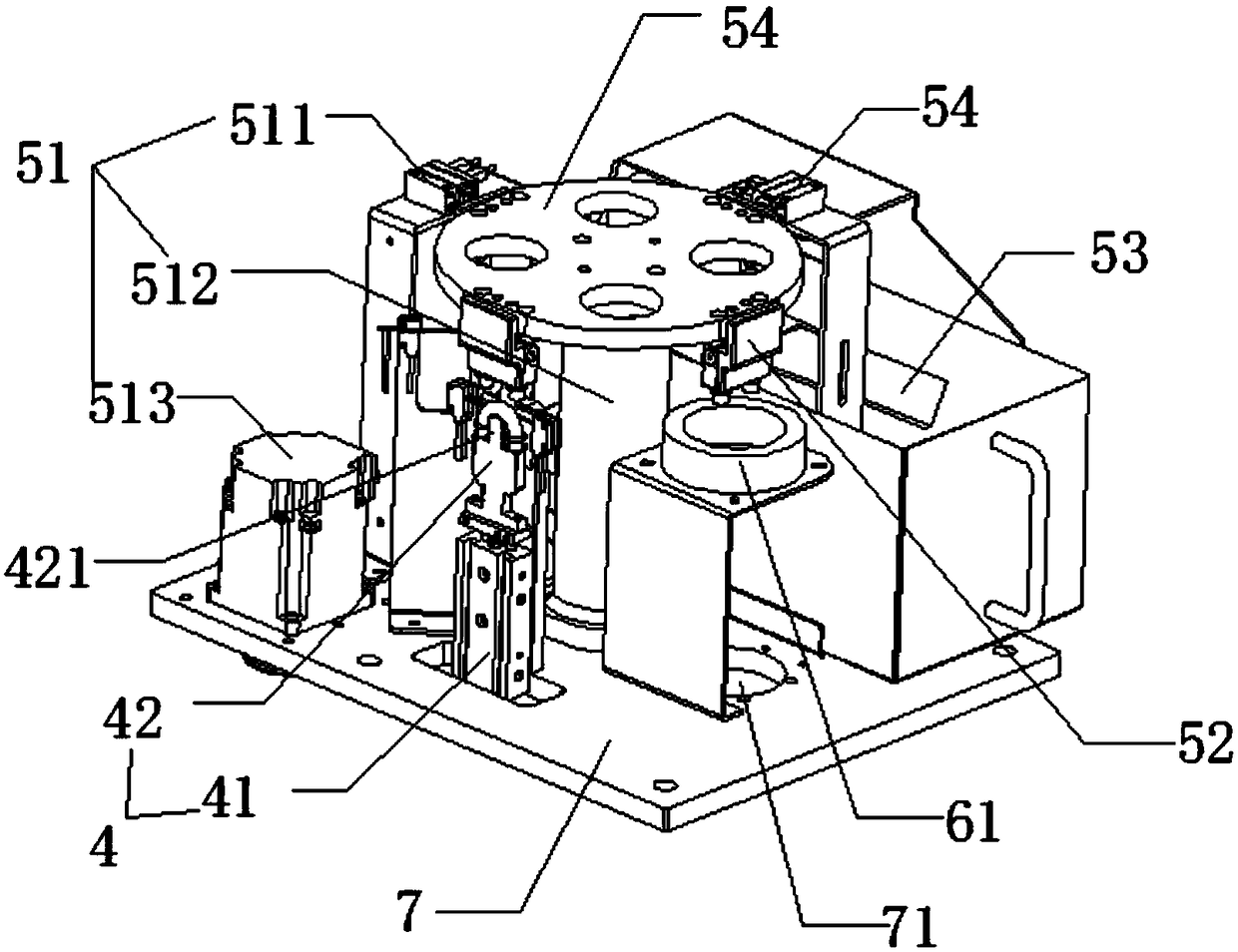

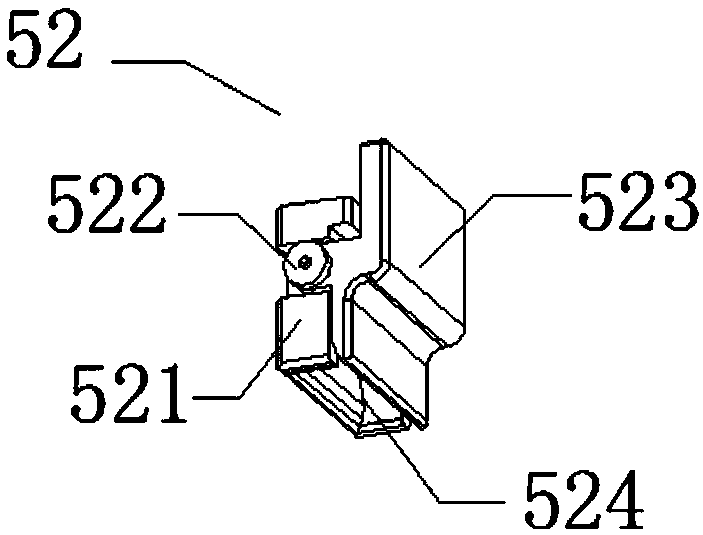

[0052] The detection component includes jacking module 4, gripper module 5, detection camera module 6, detection component fixing plate 7, jacking module 4 includes jacking cylinder 41, U-shaped tube positioning plate 42, U-shaped tube positioning plate 42 vertical screws are fixed on the top surface of the power output shaft of the jacking cylinder 41, and the upper end of the U-shaped tube positioning plate 42 is processed with an inverted T-shaped positioning frame 421 complementary to...

specific Embodiment example 2

[0069] An automatic insertion device for U-shaped tubes, which sequentially includes: a vibration plate 1 (prior art), a first vibration transmission plate 2, a detection component, a third vibration transmission plate 3, Distribution components, capture components;

[0070] The outlet 11 of the vibration plate 1 is connected to the inlet end of the first vibration transmission plate 2, and a detection component is installed behind the outlet end of the first vibration transmission plate 2;

[0071] The detection component includes jacking module 4, gripper module 5, detection camera module 6, detection component fixing plate 7, jacking module 4 includes jacking cylinder 41, U-shaped tube positioning plate 42, U-shaped tube positioning plate 42 vertical screws are fixed on the top surface of the power output shaft of the jacking cylinder 41, and the upper end of the U-shaped tube positioning plate 42 is processed with an inverted T-shaped positioning frame 421 complementary to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com