Mistake-proofing assembly system and battery PACK assembly mistake-proofing control method and device

An assembly system and control method technology, applied in the field of battery PACK, can solve problems such as wrong selection of bolts, unqualified bolt fastening, and difficulty in automatic installation, so as to achieve the effect of correct selection and improved assembly pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

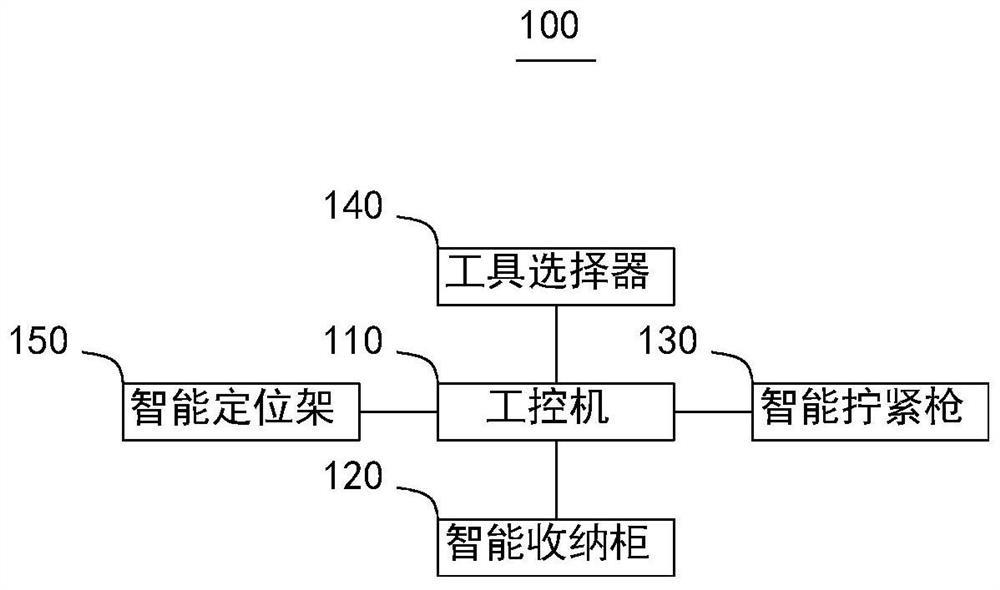

[0039] see figure 1 , figure 1 Shown is a structural block diagram of the error-proof assembly system 100 provided in this embodiment. The error-proof assembly system 100 provided in this embodiment includes an industrial computer 110, an intelligent storage cabinet 120, an intelligent tightening gun 130, a tool selector 140 and an intelligent positioning frame 150, an intelligent storage cabinet 120, an intelligent tightening gun 130, a tool selector 140 and The intelligent positioning frame 150 is electrically connected to the industrial computer 110 respectively.

[0040] The smart storage cabinet 120 is provided with a plurality of storage drawers for respectively storing different types of bolts, that is, a plurality of different types of bolts are respectively placed in the plurality of storage drawers, and the bolt model information corresponding to each storage drawer of the smart storage cabinet 120 Entered in the industrial computer 110.

[0041]The smart tighteni...

no. 2 example

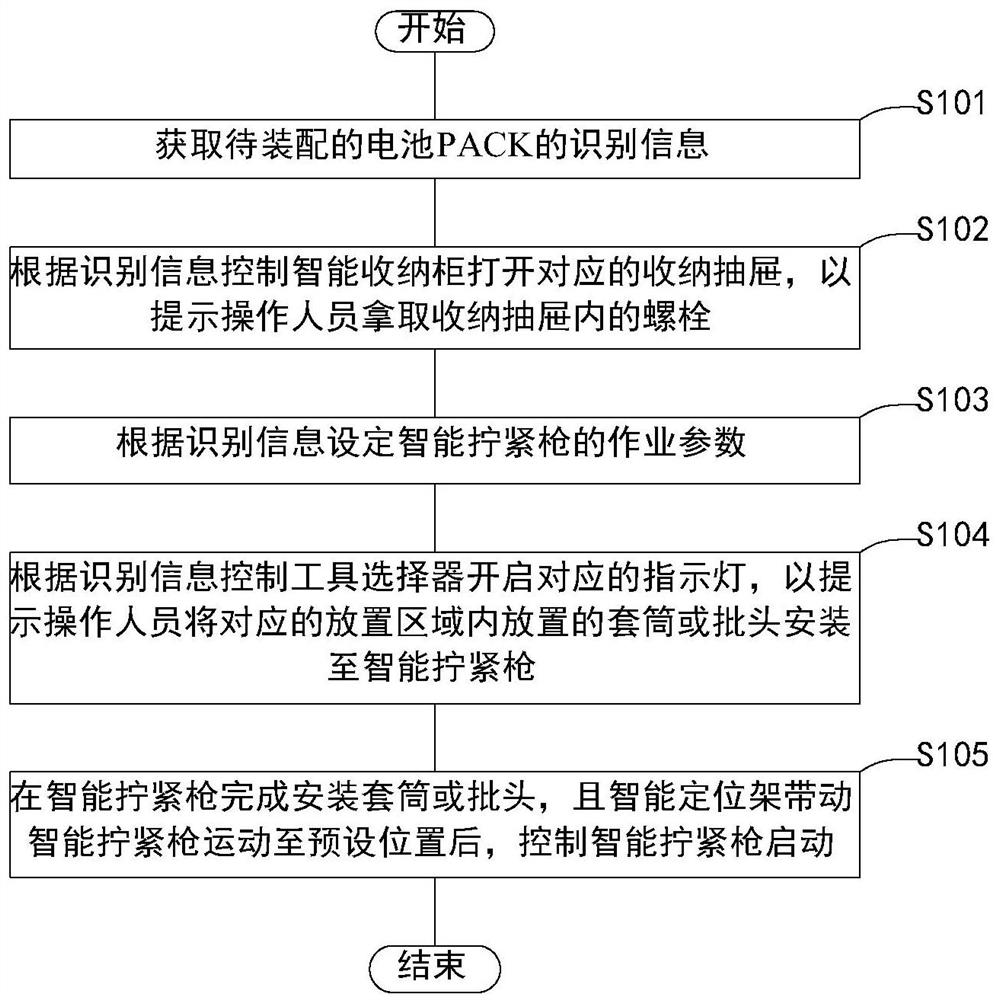

[0051] see figure 2 , figure 2 Shown is a flow chart of the battery PACK assembly error prevention control method provided in this embodiment. The battery PACK assembly error prevention control method is applied to the error prevention assembly system 100 provided in the first embodiment. The battery PACK assembly error prevention control method can prompt the operator to select the corresponding type of bolt and socket or bit according to different battery PACKs. , and by setting the operating parameters of the intelligent tightening gun 130 to ensure that the bolts are tightened in place, the qualified rate of assembly is improved. The battery PACK assembly error prevention control method provided in this embodiment includes the following steps:

[0052] Step S101, acquiring the identification information of the battery PACK to be assembled.

[0053] In practical application, the battery PACK is placed in a fixed position, and the identification code of the battery PACK...

no. 3 example

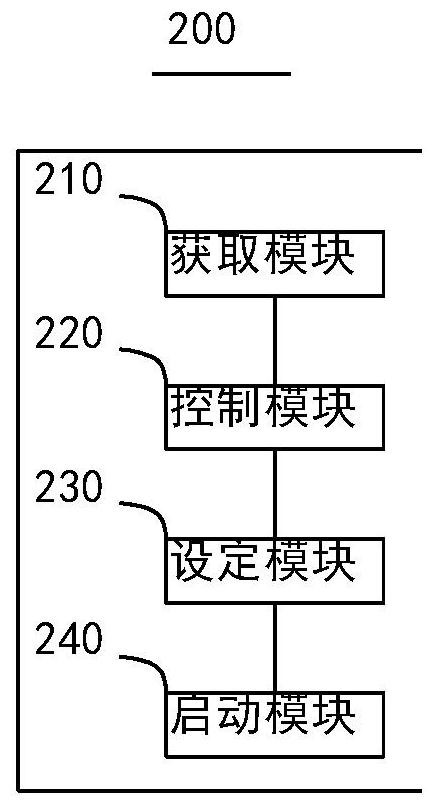

[0065] see image 3 , image 3 Shown is a structural block diagram of the battery PACK assembly error prevention control device 200 provided in this embodiment, and the battery PACK assembly error prevention control device 200 is applied to the error prevention assembly system 100 provided in the first embodiment. The battery PACK assembly error prevention control device 200 includes: an acquisition module 210 , a control module 220 , a setting module 230 and a startup module 240 .

[0066] The acquiring module 210 is configured to acquire the identification information of the battery PACK to be assembled. It can be seen that the acquisition module 210 is used to execute step S101 of the battery PACK assembly error prevention control method provided in the second embodiment.

[0067] The control module 220 is configured to control the smart storage cabinet 120 to open the corresponding storage drawer according to the identification information, so as to prompt the operator t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com