Mechanical photo switch

An optical switch and mechanical technology, applied in the field of optical path switching components, can solve the problems of inaccurate alignment, difficult alignment accuracy, loss of alignment accuracy, etc., to achieve easy control and maintenance, improve assembly pass rate, and easy alignment The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

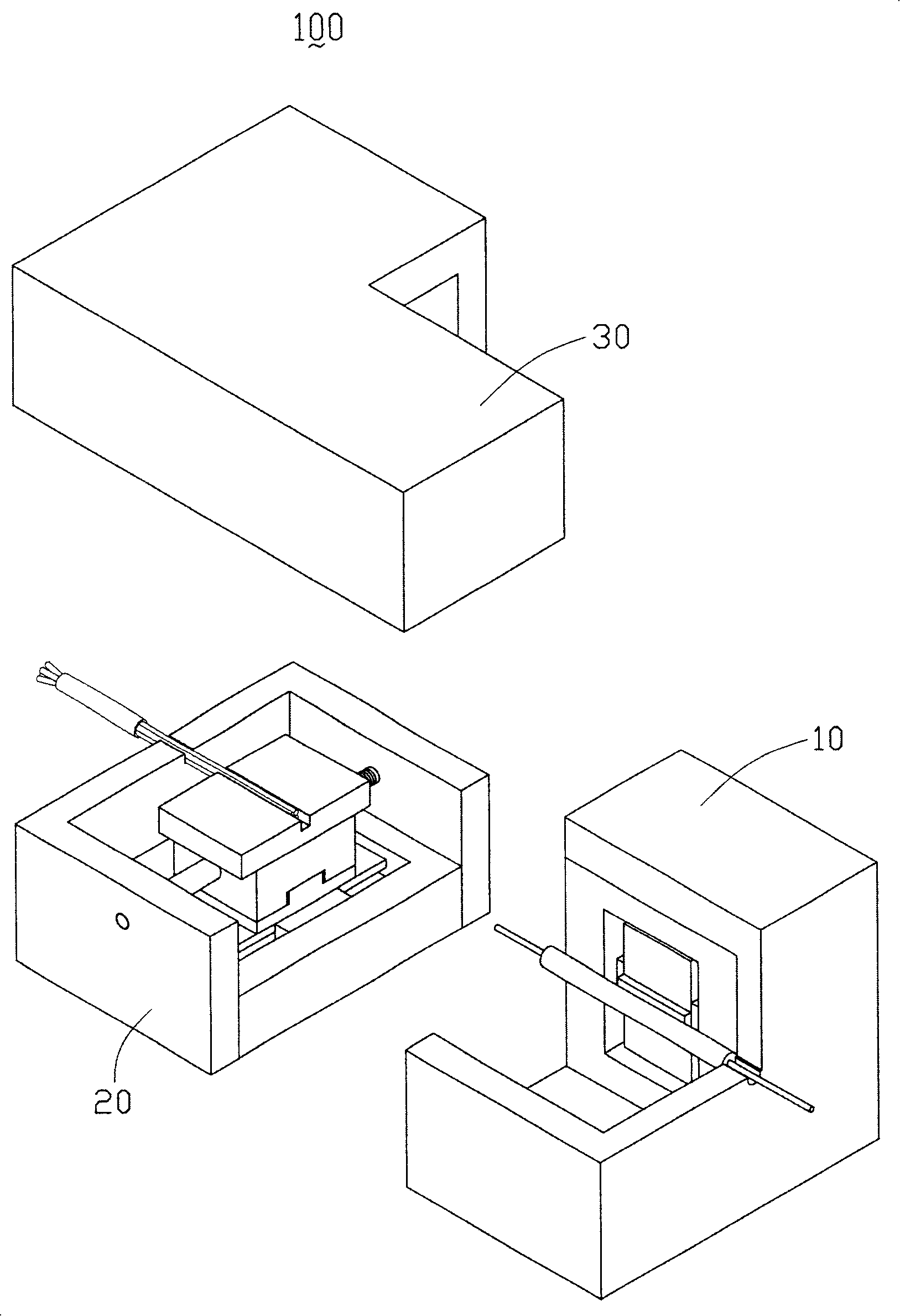

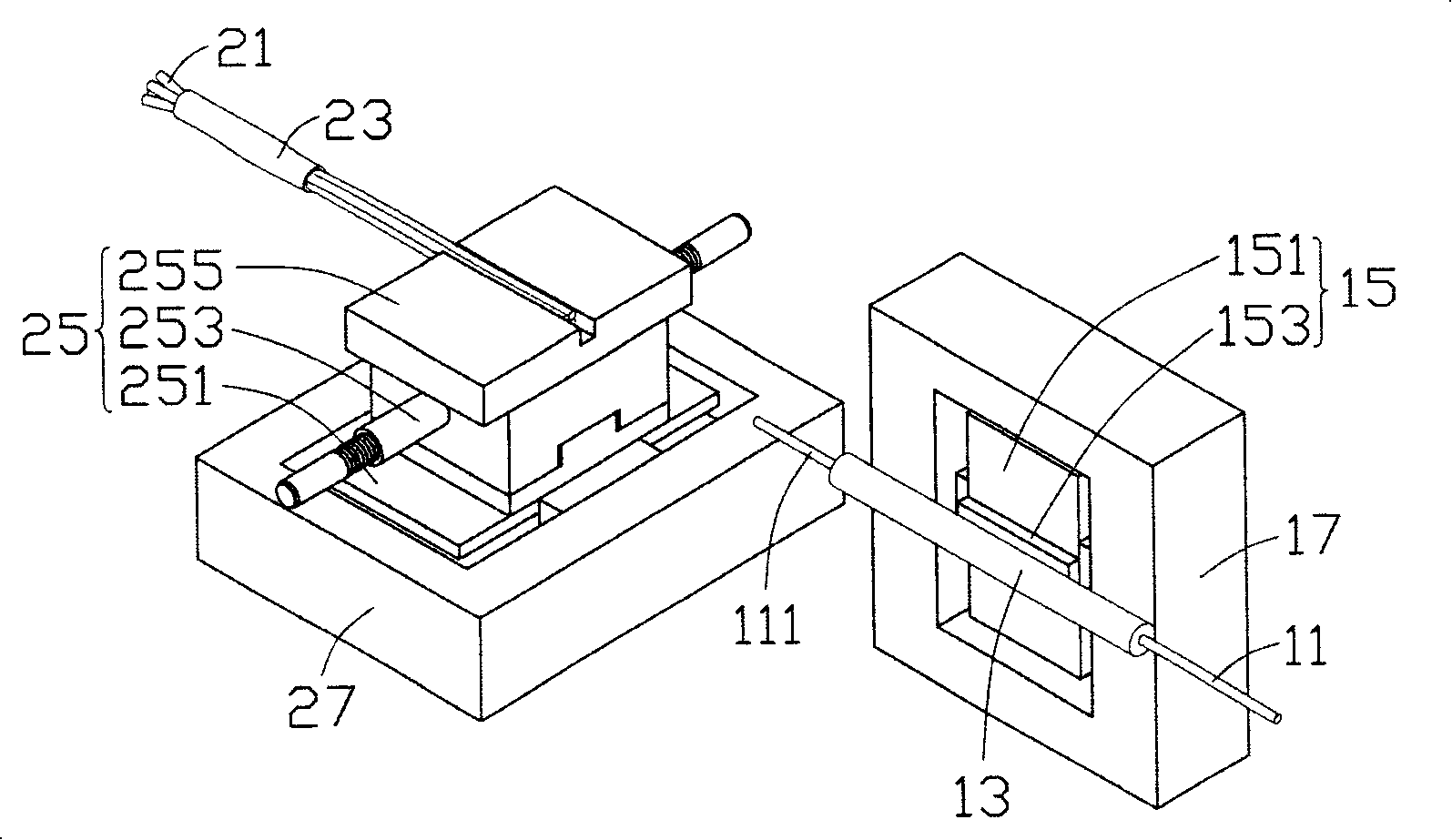

[0043] figure 1 It is a three-dimensional exploded view of the mechanical optical switch of the present invention. The mechanical optical switch 100 includes a first optical fiber module 10, a second optical fiber module 20 and an upper cover 30, wherein the first optical fiber module 10 is an input optical fiber module , the second fiber optic module 20 is an output fiber optic module.

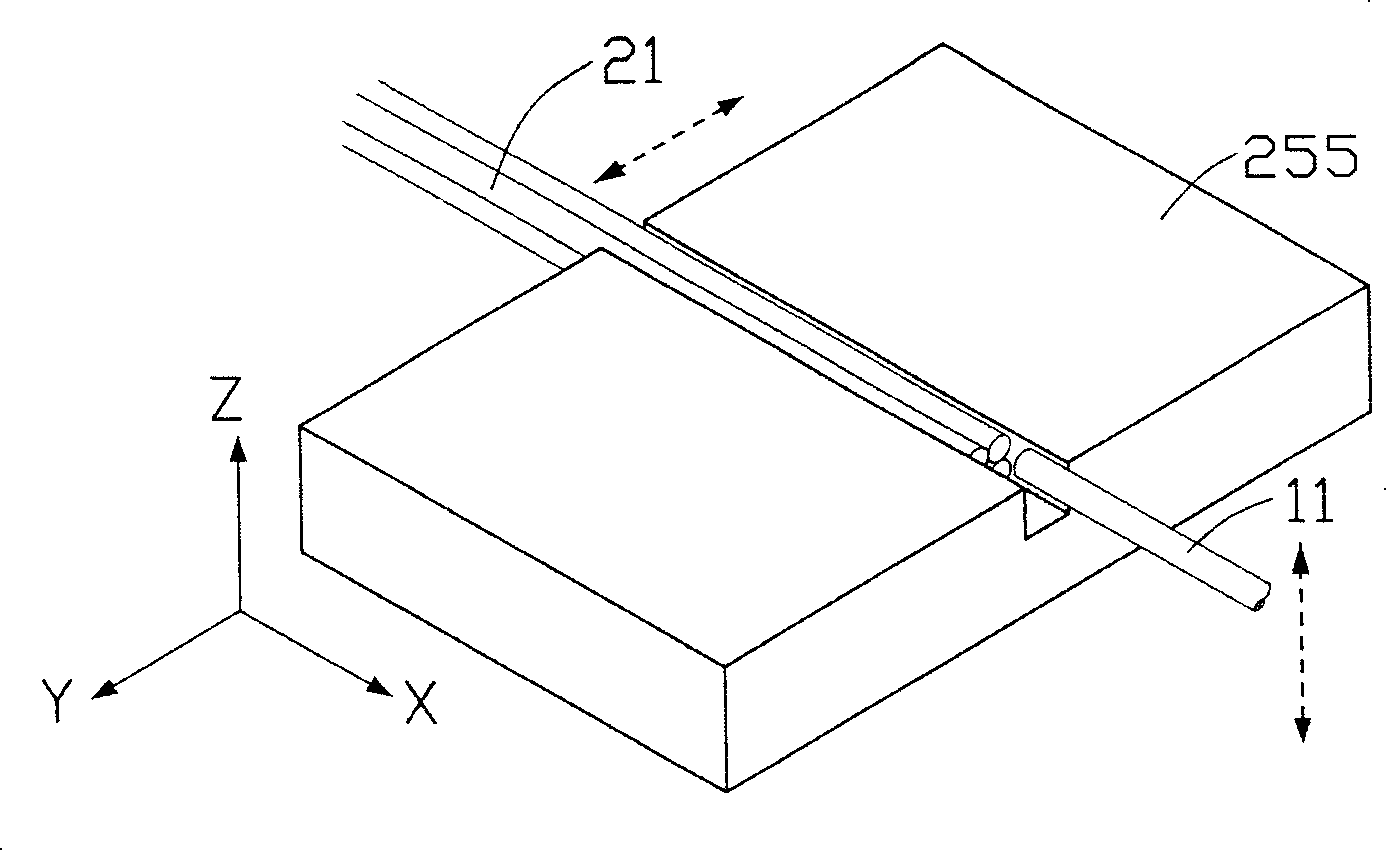

[0044] Please also refer to figure 2 , the first optical fiber module 10 includes a first optical fiber 11 , a ferrule 13 covering the first optical fiber 11 , an optical fiber switching device 15 and a base 17 . Wherein, a relay (not shown) is built in the base 17 , the fiber switching device 15 is accommodated in the base 17 , and the bushing 13 is fixedly installed on the fiber switching device 15 . The fiber switching device 15 includes a swing element 151 and a sleeve fixing element 153, which can drive the sleeve 13 and the first optical fiber 11 to move vertically, and the first opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com