Tubing coupling buckle installation auxiliary device

A technology for connecting joints and installation devices, applied in the field of tooling and fixtures, can solve problems such as low work efficiency, wrong buckle installation, etc., and achieve the effect of high assembly qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

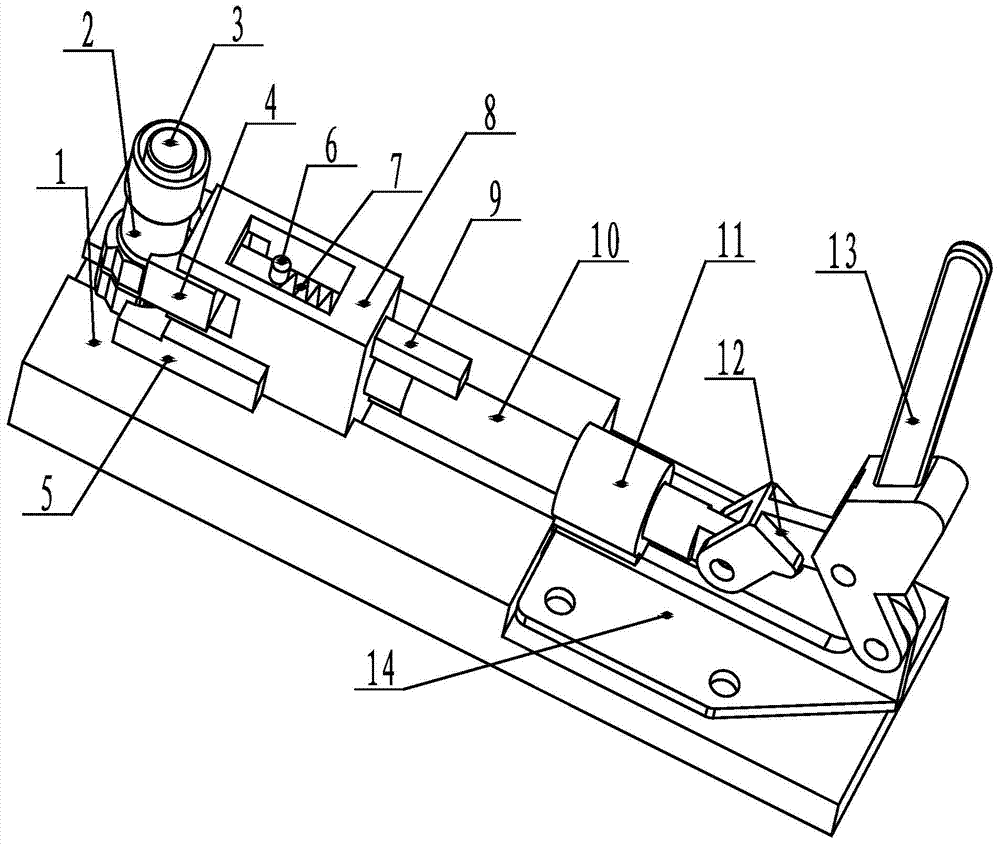

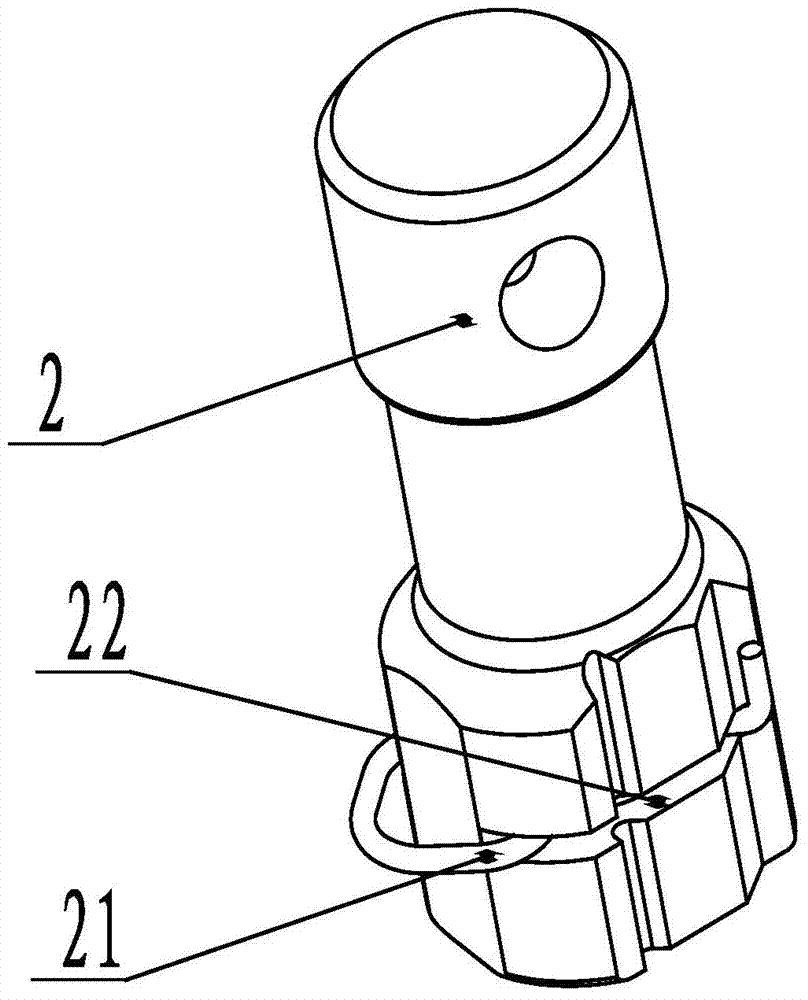

[0016] Such as figure 1 and figure 2 An auxiliary device for installing a buckle 21 of a pipe connecting joint 2, mainly comprising a base 1, a handle 13 and a push rod 10, the handle 13 is connected to the push rod 10 through a connecting rod 12, and the push rod 10 is located at the limit In the position cover 11, the limit cover 11 is connected with the base 1 through the fixed plate 14, the handle 13 is connected with the fixed plate 14 through a hinge, the push rod 10 is fixedly connected with the moving block 8, and the moving block Extrusion block 4 is installed in 8, and buckle placement table 5 and fixed column 3 are fixed on the left side of said base 1.

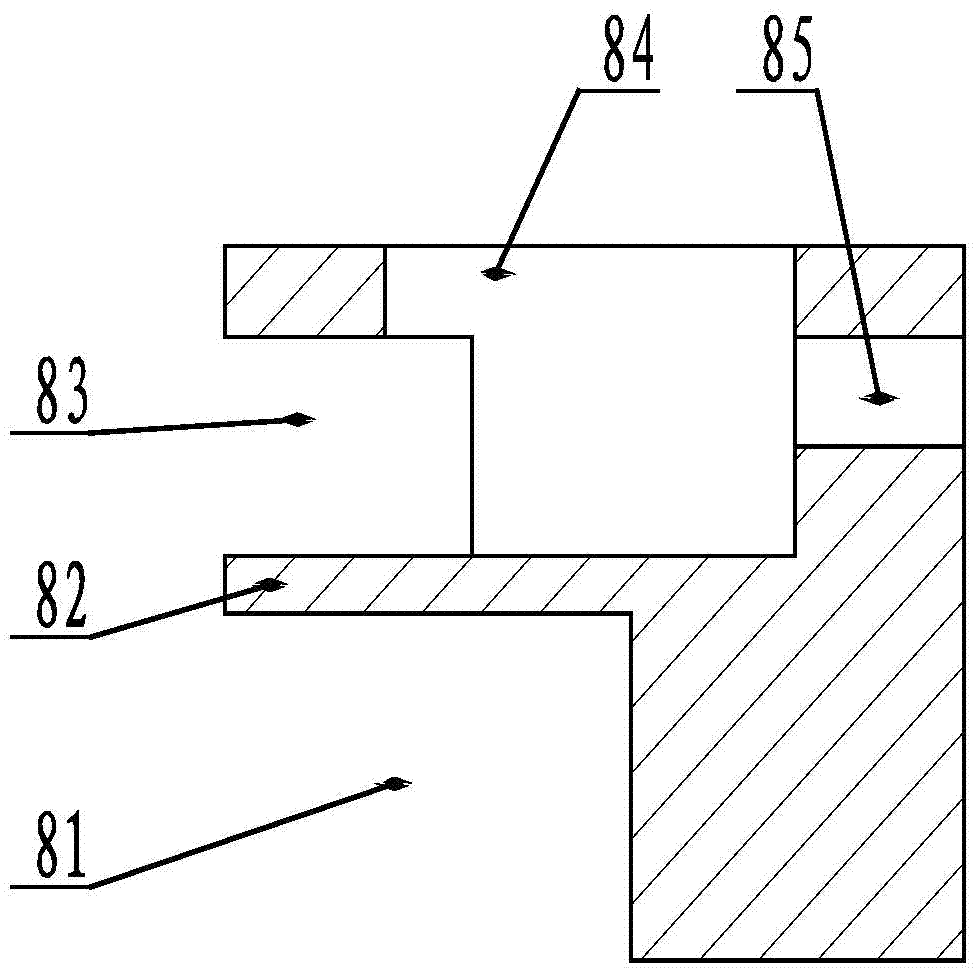

[0017] A guide rod 9 is arranged behind the extruding block 4 , and a spring pin 6 is arranged above the guide rod 9 . The bottom of the left side of the moving block 8 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com