Fixture for machining submersible pump shell blank

A blank processing, submersible pump technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of easy jumping, low processing accuracy of submersible pump body blanks, and difficulty in ensuring reliable contact between clamping jaws and submersible pump pump body blanks, etc. Not easy to jump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

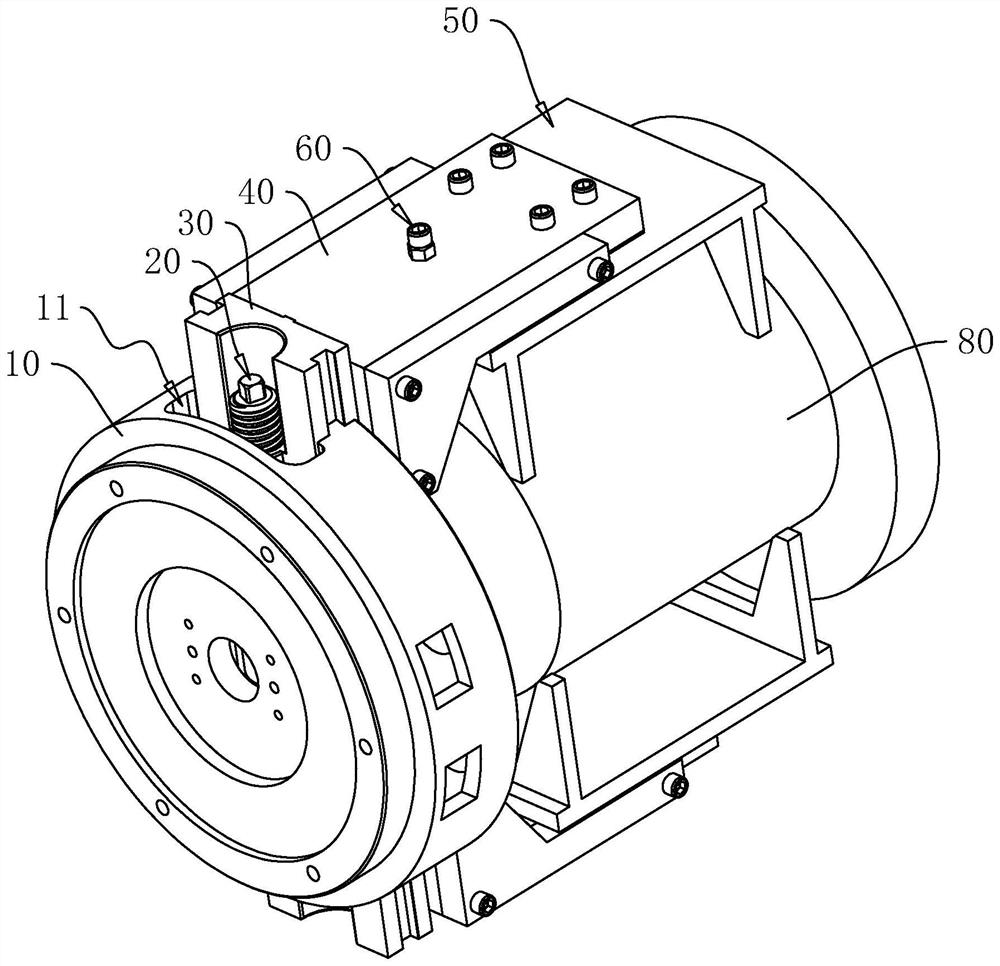

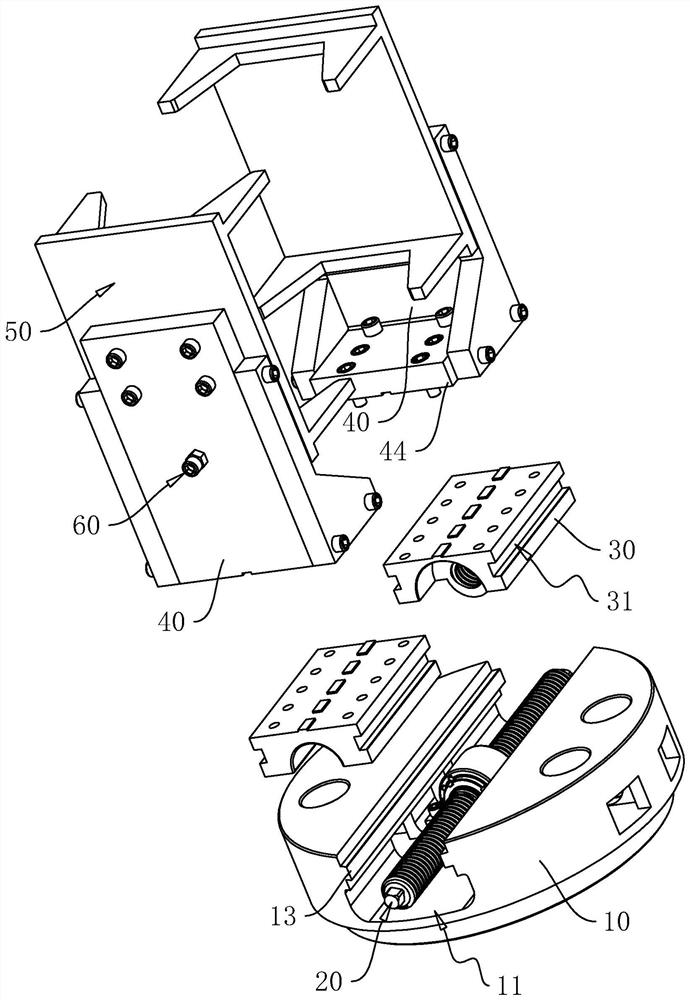

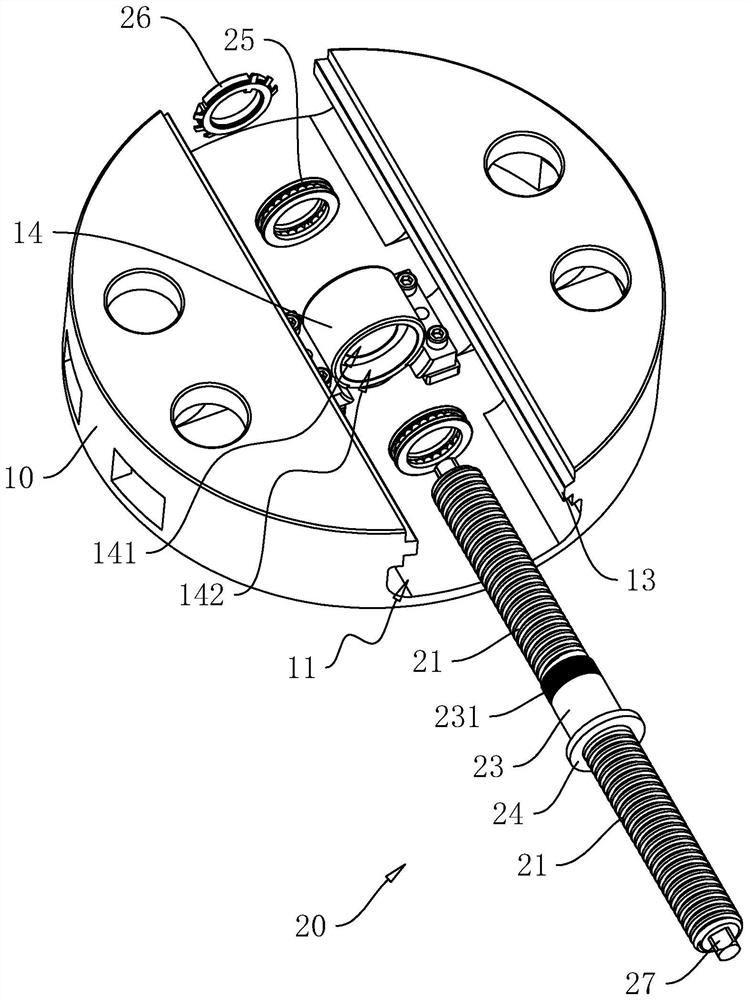

[0044] refer to figure 1, The submersible pump housing blank processing fixture includes a chuck body 10 , a two-way screw 20 , a slider 30 , a support plate 40 and a clamping jaw 50 . The two-way screw 20 is rotatably connected to the chuck body 10 , the two-way screw 20 is fixed relative to the chuck body 10 along its own axial direction, and the slider 30 is slidingly connected to the chuck disc along the radial direction of the chuck body 10 . On the body 10, the two-way screw 20 has two transmission threaded portions 21 with opposite directions of rotation. The two sliding blocks 30 are connected with threads, the supporting plates 40 are fixed on the sliding blocks 30 in a one-to-one correspondence, and the clamping jaws 50 are fixed on the supporting plates 40 in a one-to-one correspondence. Rotating the two-way screw 20 can drive the two clamping jaws 50 to be close to each other to clamp the blank 80 .

[0045] refer to figure 2 and image 3 , the chuck body 10 i...

Embodiment 2

[0058] refer to Figure 5 The difference between this embodiment and the first embodiment is that the support plate 40 provides support for the clamping jaw 50 through the swing column 512 and the swing groove 43 . Specifically, a swing column 512 is fixed on the side of the base plate 51 close to the support plate 40 . The axis of the swing column 512 and the axis of the chuck body 10 are perpendicular to each other. The side of the support plate 40 close to the base plate 51 is provided with a swing slot 43 , two ends of the swing slot 43 penetrate two opposite side walls of the support plate 40 , and the swing column 512 can slide from one end of the swing slot 43 and be inserted into the swing slot 43 to swing. The post 512 rotates relative to the support plate 40 about its own circumference. When the swing column 512 is inserted into the swing slot 43 , there is a deformation gap between the base plate 51 and the support plate 40 .

[0059] The difference between this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com