Die opening method of core shooter

A core shooter and core mold technology, applied in molding machines, casting molding equipment, metal processing equipment, etc., can solve the problems affecting the socket end accuracy of ductile iron pipes, low sand core accuracy, sand core damage, etc., to achieve Reduce the probability of damage, improve accuracy and yield, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

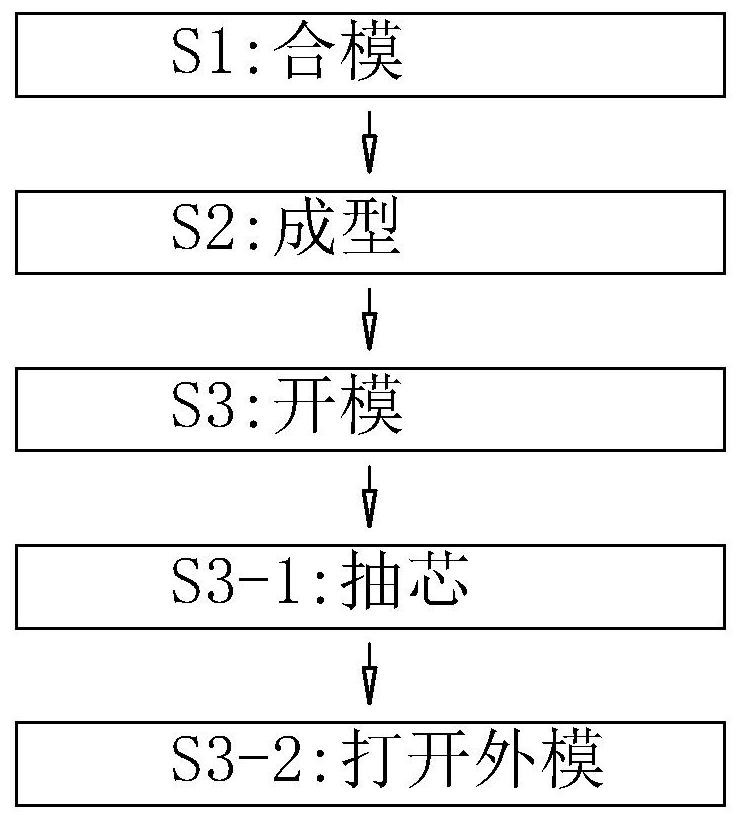

[0053] The embodiment of the present application discloses a mold opening method of a core shooter. refer to figure 1 , the core making and mold opening method of the core shooter includes the following steps:

[0054] S1: Mold closing, splicing the lower mold, upper mold, outer mold and core mold together, forming a cavity between the lower mold, upper mold, outer mold and core mold;

[0055] S2: Molding, spraying the core sand into the mold cavity, and passing triethylamine gas into the mold cavity, the core sand forms strength under the catalysis of triethylamine gas, so that the core sand aggregates into a sand core;

[0056] S3: open the mold, open the upper mold, core mold and outer mold;

[0057] Among them, S3 also includes S3-1: core pulling and S3-2 opening the outer mold;

[0058] S3-1: Core pulling, remove the upper mold and pull out the core mold from the sand core, and both the upper mold and the core mold slide along their own axial direction away from the lo...

Embodiment 2

[0068] The embodiment of the present application discloses a mold opening method of a core shooter. The difference from Embodiment 1 is that in S3-1: core pulling, the upper mold is removed and the core mold is pulled out from the sand core, the upper mold slides along the axial direction of the core mold away from the lower mold, and the core mold All slide along their own axial direction away from the upper die under the guide;

[0069] S3-2: Open the outer mold, the outer mold includes the first half mold, the second half mold, the third half mold and the fourth half mold, the first half mold, the second half mold, the third half mold and the fourth half mold The molds all slide towards the side away from the mandrel along the direction perpendicular to the axis of the mandrel.

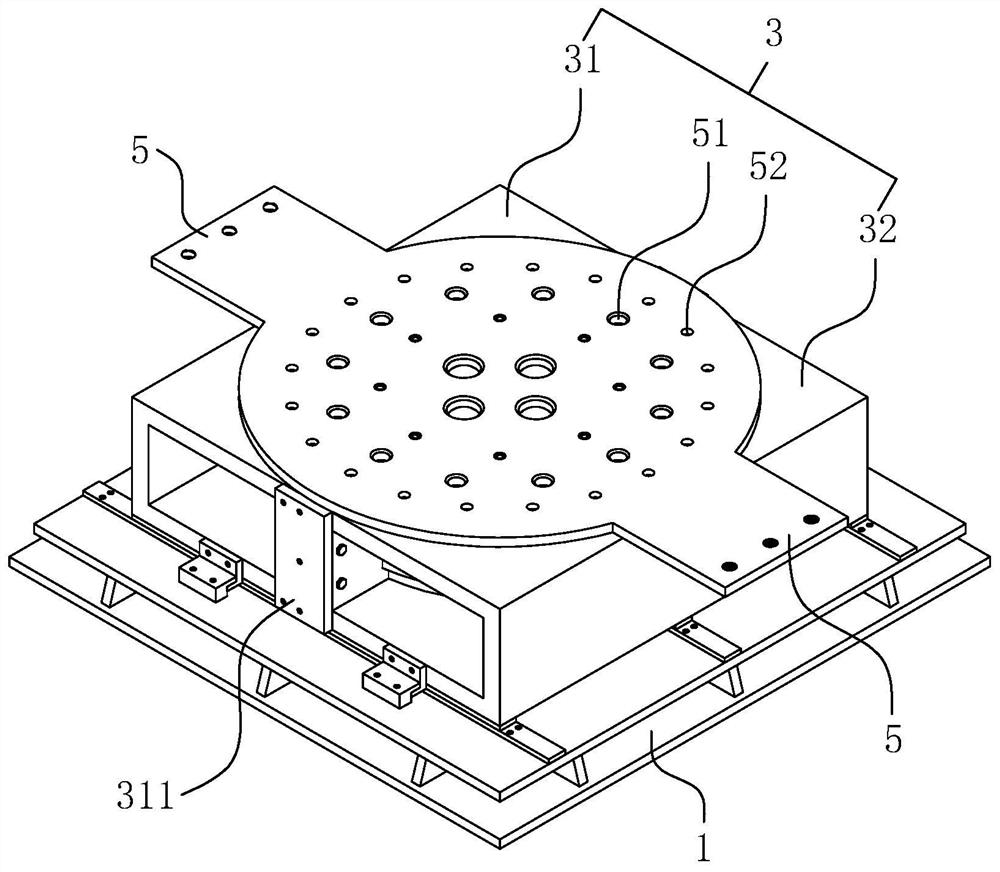

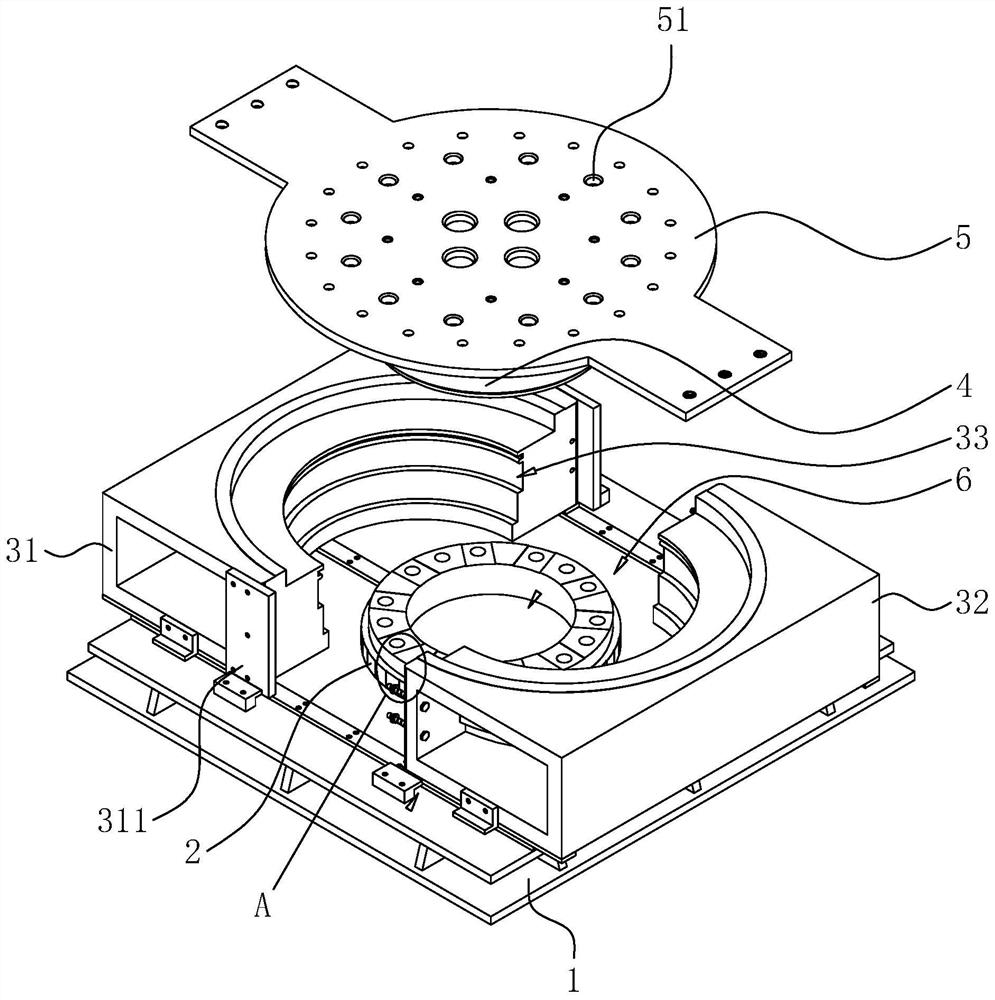

[0070] The embodiment of the present application also discloses a core box using the above mold opening method, referring to Image 6 , The core box includes a base 1, a lower mold 2, an outer mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com