Boiler feedwater sequential control logic optimization system and control method

A logic optimization and boiler technology, which is applied in the control/regulation system, liquid level control, non-electric variable control, etc., can solve the problem that the measurement value jump of the liquid level information is not easy to eliminate, etc., and achieve easy to check on-site management and remote monitoring Good management, good reliability, not easy to jump effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

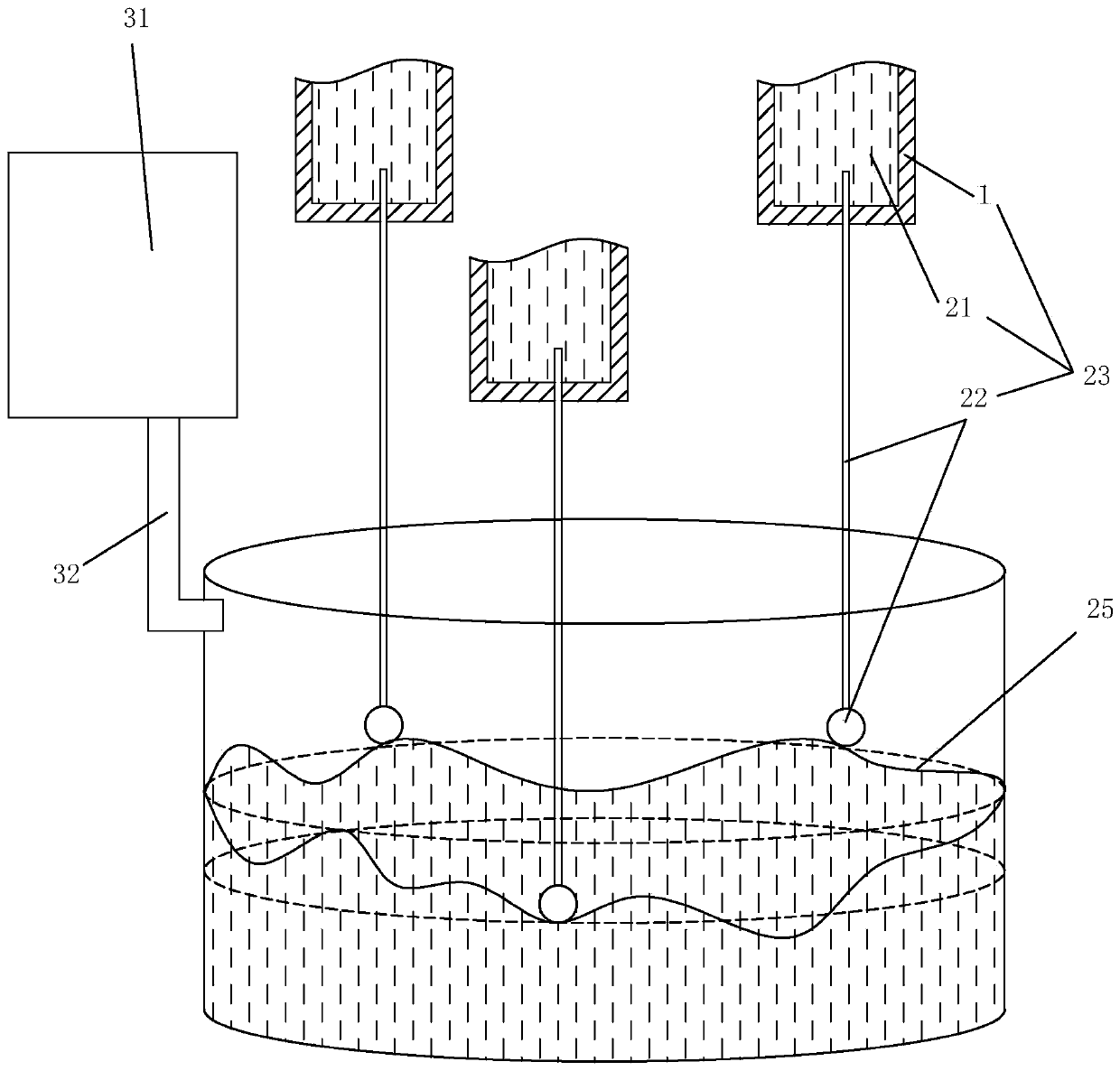

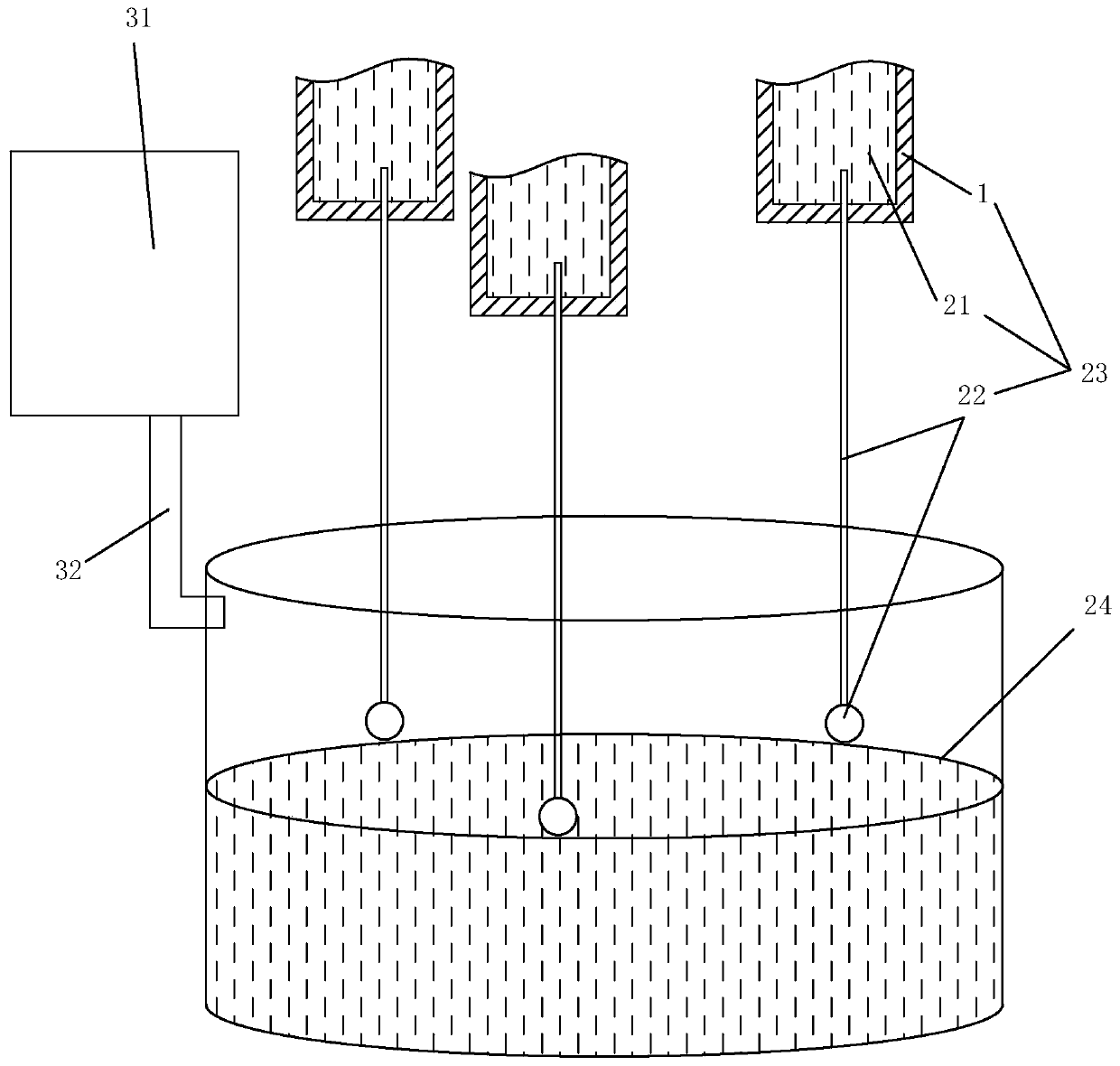

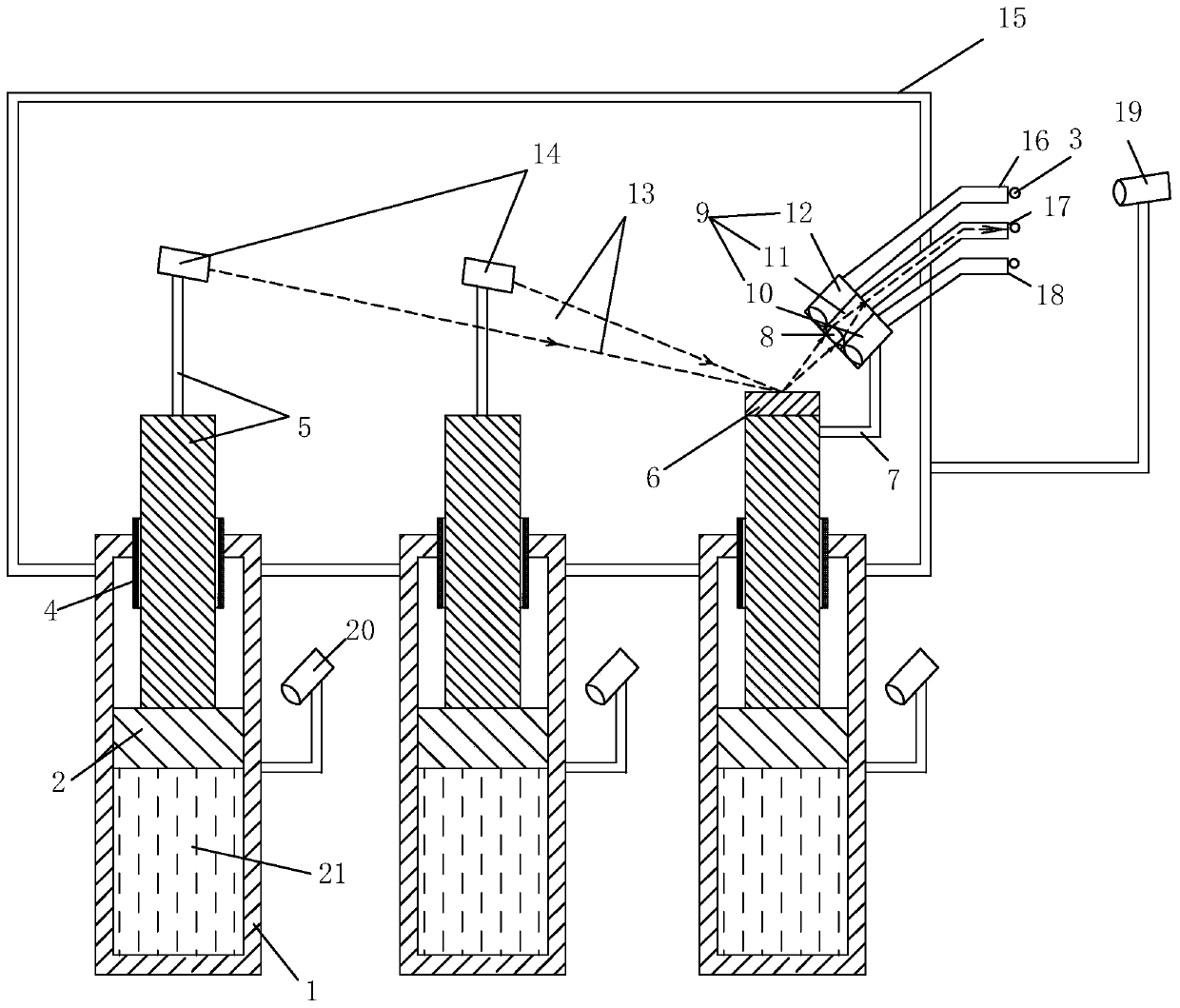

[0039]Embodiment: Boiler feed water sequential control logic optimization system, see Figure 1-Figure 8 As shown, the boiler level gauge body 23 is included, and the boiler level gauge body includes a liquid level display tube 1 equipped with a lifting liquid 21, and a water level line scale is provided on the liquid level display tube; it also includes a water supply tank 31, a controller, Water supply pipe 32, electromagnetic valve 33 arranged on the water supply pipe, shading cover 15 and three light guide columns; there are three boiler liquid level gauge bodies;

[0040] The shading cover is tightly and fixedly connected to the three display tubes through the three bottom cover holes on the lower bottom surface; each liquid level display tube is provided with a lumen connected to the corresponding liquid level display tube on the upper surface. The vertical holes of each liquid level display tube are respectively sealed and fixedly connected with vertical tubes 4, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com