Forming mechanism of blister packaging machine

The technology of a blister packaging machine and a forming mechanism, which is applied in the field of pharmaceutical machinery, can solve the problems of upper mold and lower mold jumping, affecting the quality of blister molding, etc., and achieves the effect of firm and reliable locking, good application effect, and not easy to jump.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

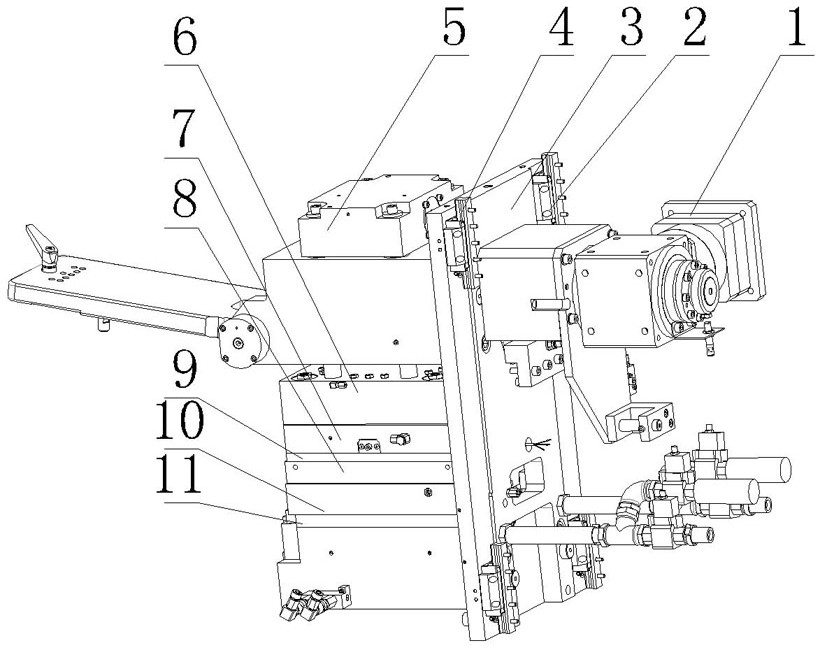

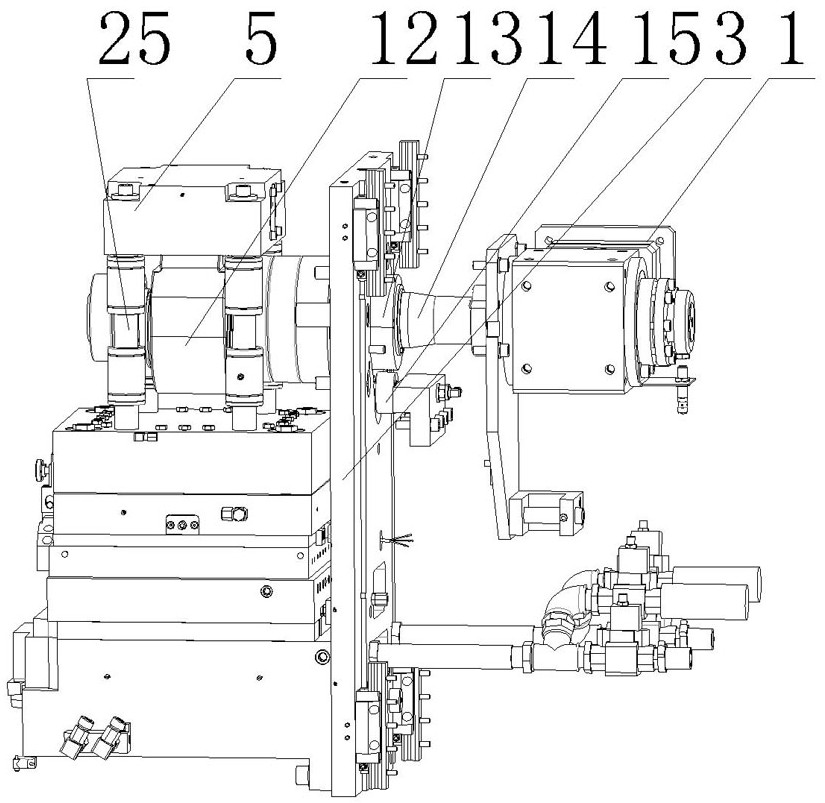

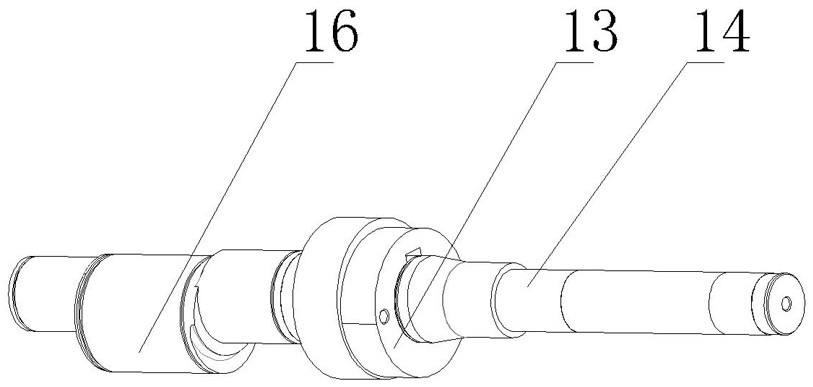

[0021] Referring to the accompanying drawings, the forming mechanism of this blister packaging machine includes an upper forming die 8 and a lower forming die 10, wherein the upper forming die 8 is installed on the upper forming template 9, and the lower forming die 10 is installed on the lower forming template 11. Described lower forming mold 10 is installed on the forming frame 3 by following forming template 11, and described forming frame 3 is equipped with rotatable transmission shaft 14, and crankshaft 16 is arranged on described transmission shaft 14, and on described transmission shaft 14 The eccentric wheel 13 is installed, and the eccentric wheel 13 is in contact with the roller 15 fixed on the forming mechanism frame of the blister packaging machine, and the crankshaft 16 is connected with the moving frame 5 through the axle sleeve 12, wherein the transmission shaft 14 is connected with the driving The motor 1 is connected by transmission. The structure of the cranks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com