Hot-plug fan and its terminal base

A terminal block and hot-swappable technology, applied in the field of hot-swappable fans, can solve the problems of non-replacement, low fan and system assembly margin, poor assembly pass rate, etc., and achieve the effect of improving the assembly margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

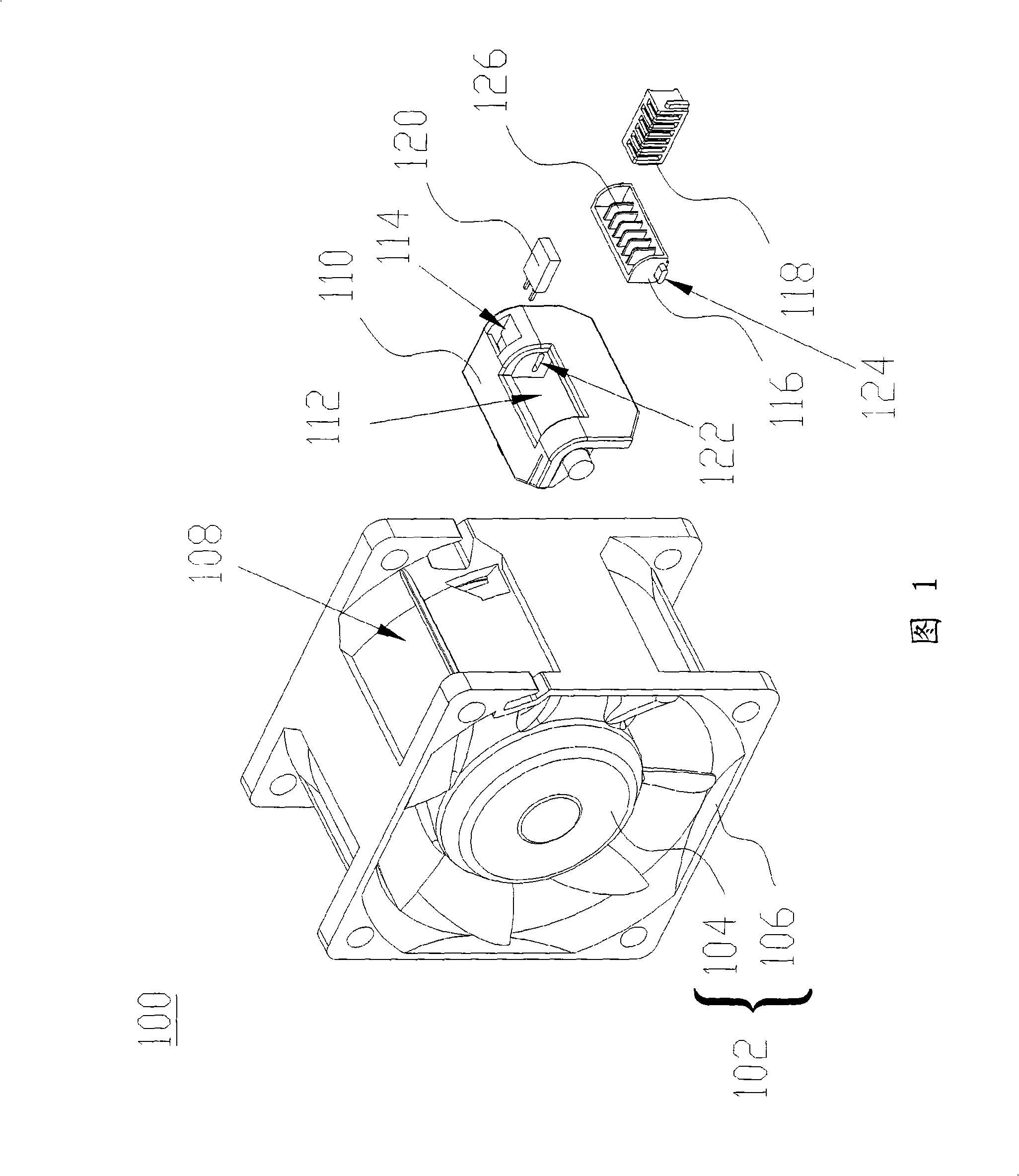

[0020] FIG. 1 is a schematic diagram illustrating a hot-swap fan 100 according to a first preferred embodiment of the present invention. The hot-swappable fan 100 of this preferred embodiment is a fan that can be hot-swapped in a system at any time. The hot-swap fan 100 includes a fan body 102 , at least one first terminal base 110 and at least one second terminal base 116 . The hot-swap fan 100 can be an axial fan or a centrifugal fan.

[0021] The fan body 102 has at least one impeller 104 and at least one fan frame 106 . The impeller 104 is accommodated in the fan frame 106 , and the fan frame 106 has at least one accommodating groove 108 around its periphery. The fan body 102 can have a control circuit board to control the operation of the impeller 104 . In addition, the control circuit board may not be required, and the impeller 104 is electrically connected to the system (or external device) via the terminals of the second terminal base 116 to receive signals from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com