Lock cylinder installing machine

A lock cylinder and rack technology, applied in the field of lock assembly equipment, can solve the problems of shell errors, affecting product qualification rate, and time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0131] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

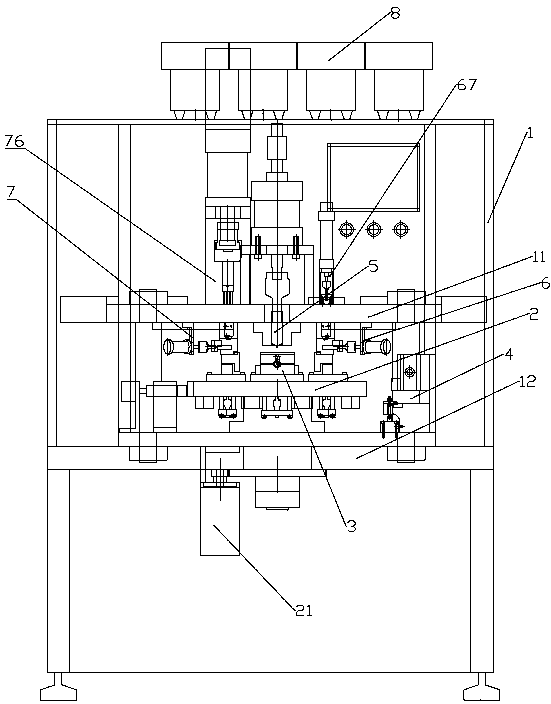

[0132] As shown in the figure, a lock cylinder installation machine includes:

[0133] Frame 1 is provided with an ingot rack 11 and a stand 12 installed from top to bottom;

[0134] A rotary table 2, which is installed on the platform 12 and is provided with a driving device 21 that can drive it to rotate and a plurality of clamping devices 3 arranged along the circumferential direction;

[0135] Tooth stain reading device 4, which is installed on a corner of the stand 12;

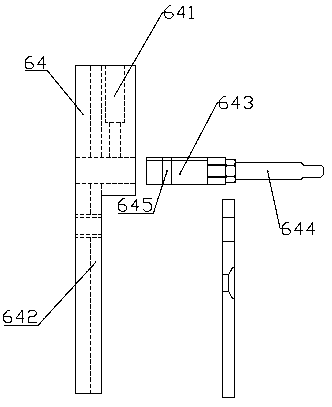

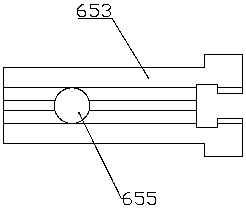

[0136] The positioning mechanism 5, the warhead flat head loading device 6 and the spring bead loading device 7 are fixedly installed on the ingot rack 11 in sequence, and all correspond to the clamping device 3 below;

[0137] The feeding device 8 is fixedly installed on the upper end of the frame 1 and communicates with the warhead flat head loading device 6 and the spring bead load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com