Mechanical arm mounting device used for gear frame

An installation device and manipulator technology, which is applied to manipulators, chucks, manufacturing tools, etc., can solve the problems of missing installation and low efficiency of gear box assembly, and achieve the effect of ensuring installation accuracy, improving production quality and workpiece assembly qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

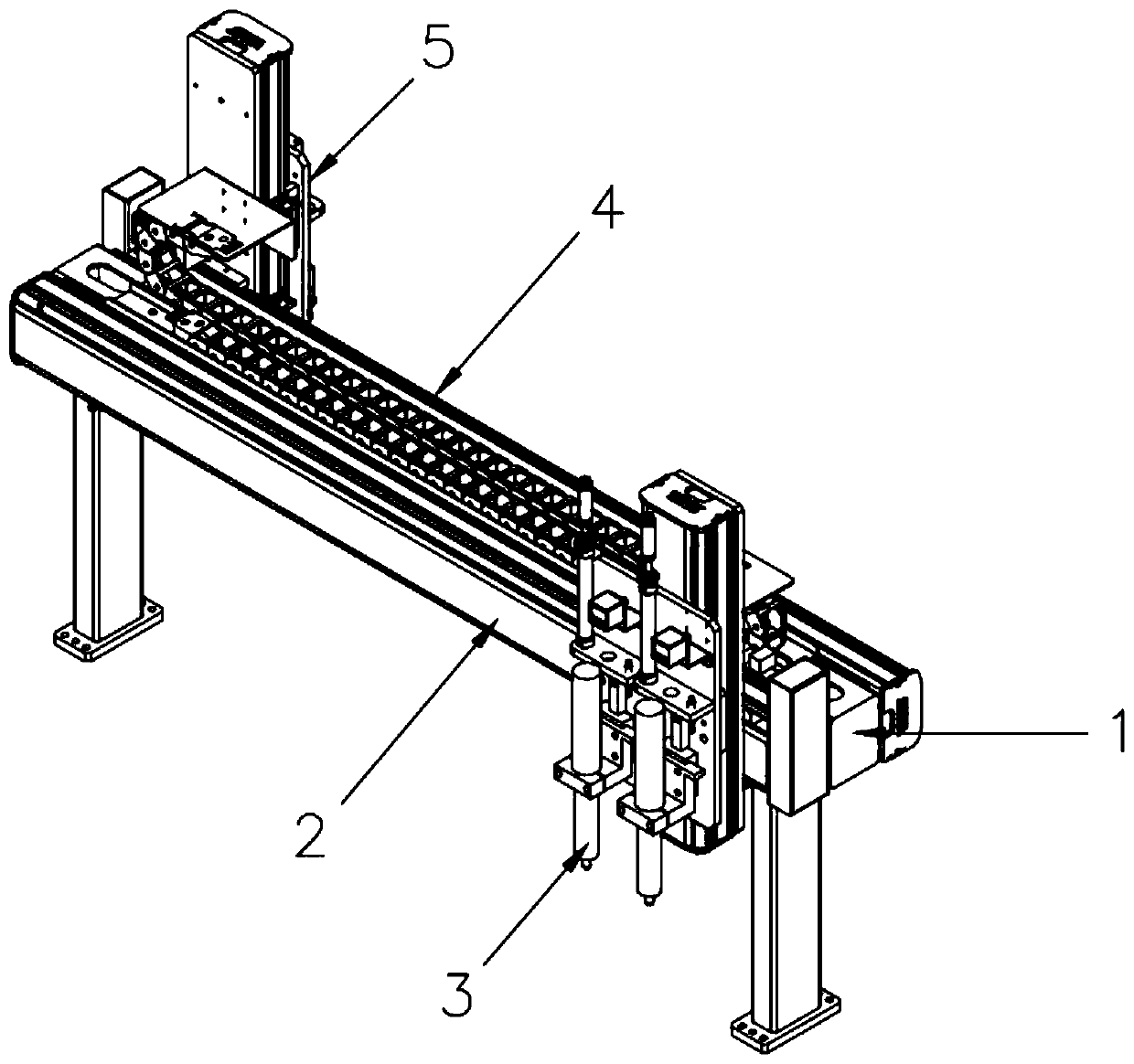

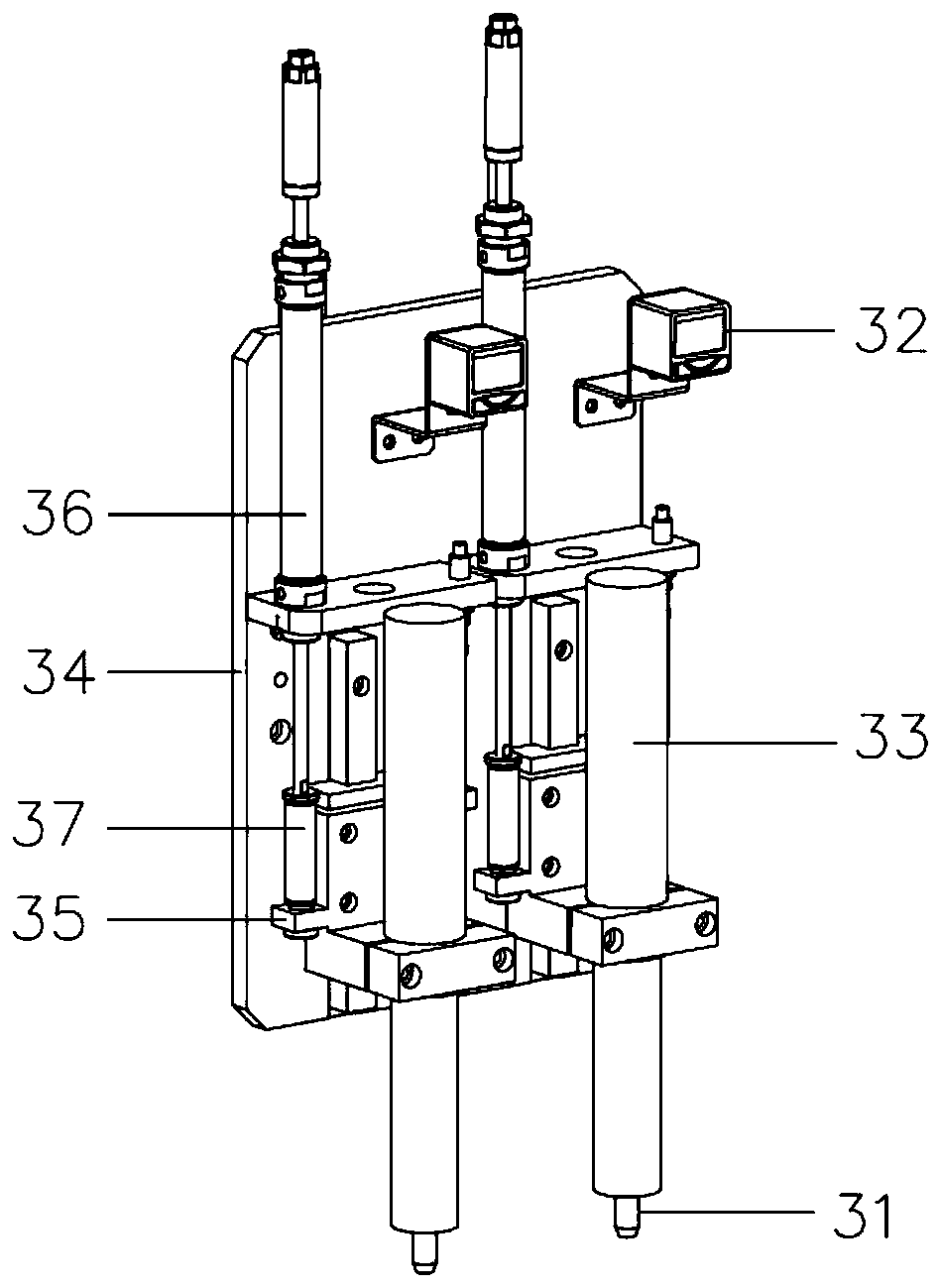

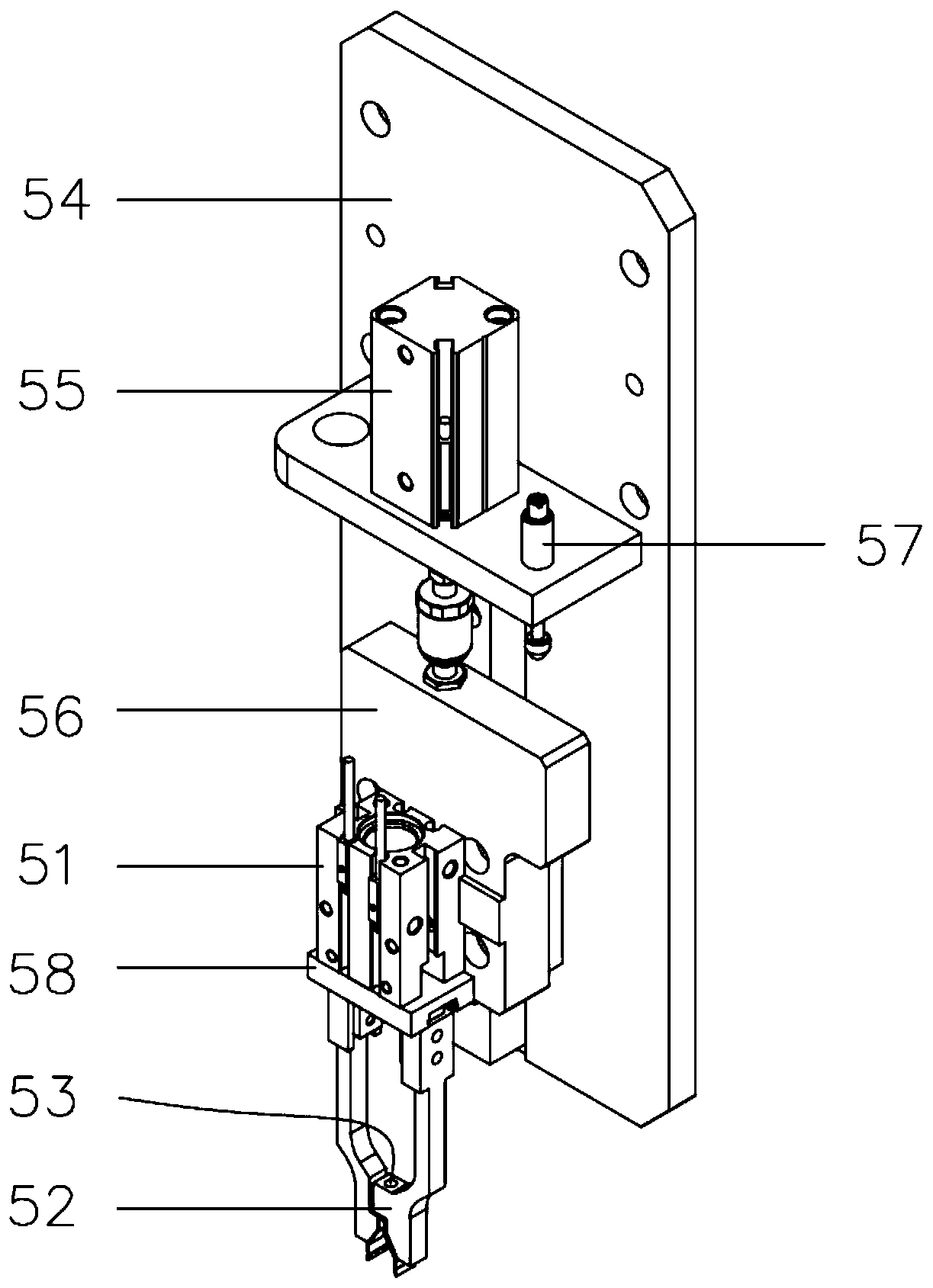

[0032] see Figure 1 to Figure 5 , a manipulator installation device for the gear frame of the present invention, comprising a beam 1, a first slide rail 2, a first manipulator assembly 3, a second slide rail 4 and a second manipulator assembly 5;

[0033] The first slide rail 2 and the second slide rail 4 are respectively arranged on both sides of the crossbeam 1, the slide rails extend along the length direction of the crossbeam 1, and the first manipulator assembly 3 is slidably connected to the first slide rail 2, so that The second manipulator assembly 5 is slidably connected to the second slide rail 4;

[0034] The first manipulator assembly 3 is used to pick up external scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com