Crank arm box seal ring assembly clamp

A technology for assembling fixtures and crank boxes, which is applied in the direction of hand-held tools and manufacturing tools, can solve problems such as inability to install, reduce work efficiency, and improper installation of sealing rings, so as to prevent wear or skew, improve assembly pass rate, The effect of meeting the requirements of dynamic sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

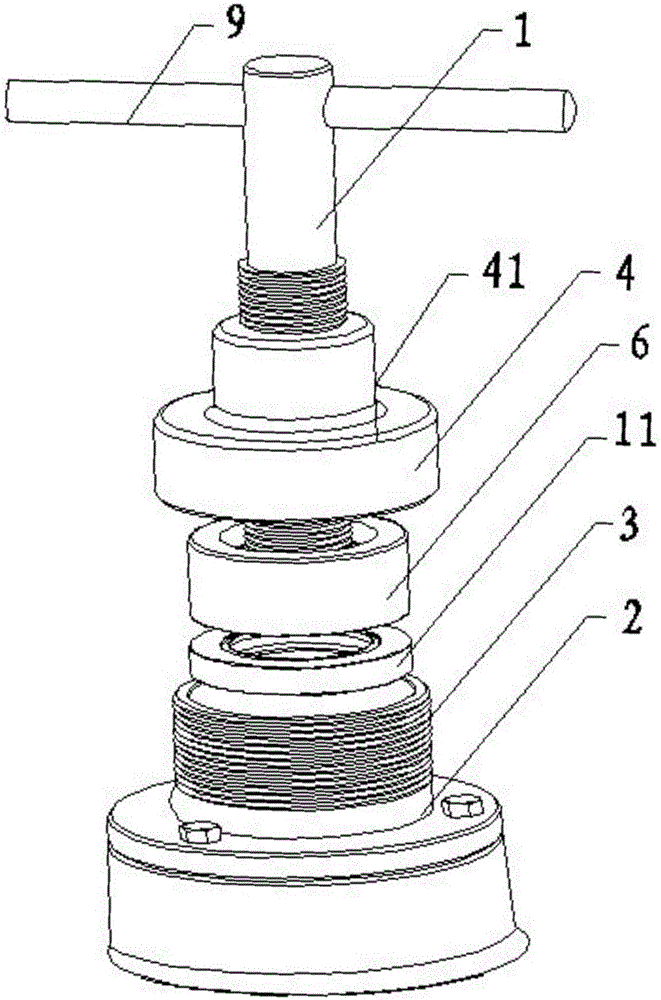

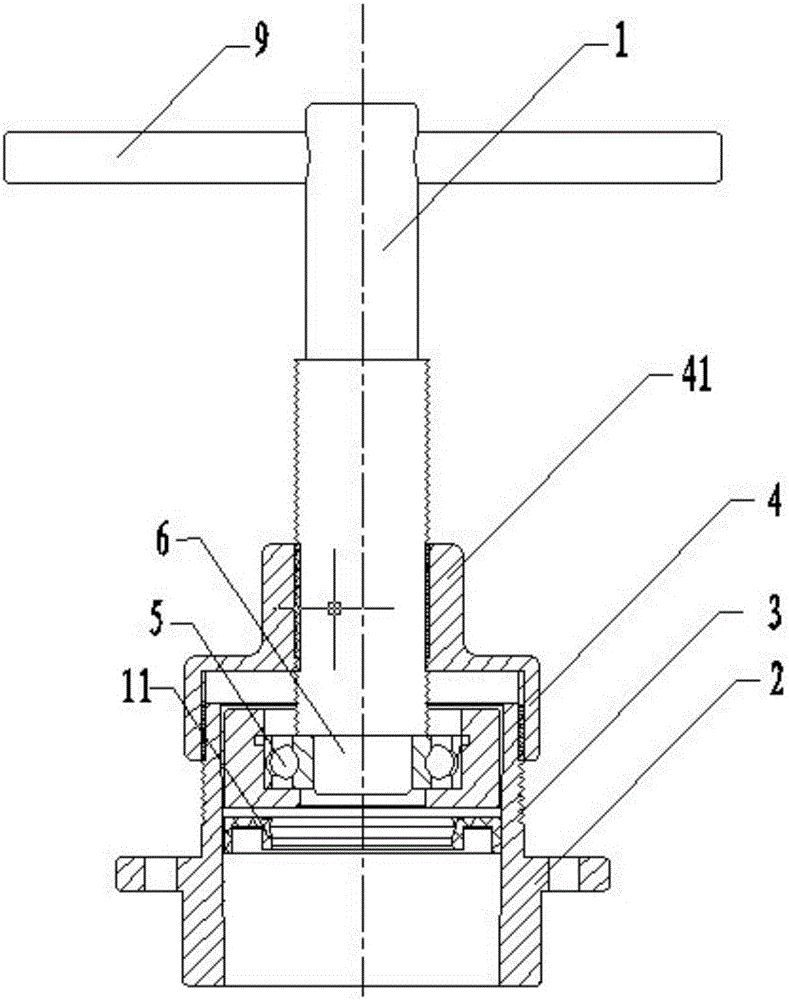

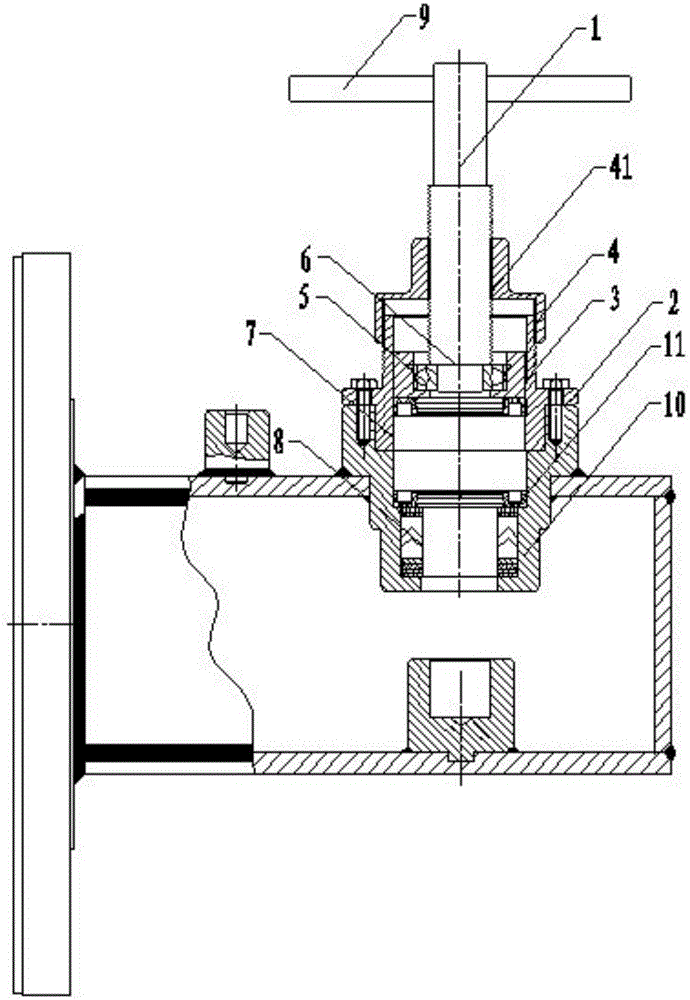

[0012] see Figure 1-3 The jig box sealing ring assembly jig shown includes a screw rod 1 and a flange 2. The flange 2 is arranged in the middle of the connecting sleeve 3, and the outer surface of the upper part of the connecting sleeve 3 is provided with external threads. A tapered through hole is arranged inside, and the diameter of the tapered through hole is large at the top and small at the bottom. A threaded sleeve 4 is connected to the upper external thread of the connecting sleeve 3. The upper end of the threaded sleeve 4 is provided with a screw connecting sleeve 41. The screw connecting sleeve 41 is provided with an internally threaded through hole that is threadedly connected with the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com