Pressing device capable of aligning lens with lens barrel and pressing method thereof

A technology of pressing device and lens, applied in installation, optics, instrument and other directions, can solve the problems of reducing assembly accuracy, assembly failure rate, pressing alignment deviation, etc., and achieve the effect of improving assembly pass rate and precise assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make your examiners make a further understanding of the present invention, hereby give a preferred embodiment and cooperate with the drawings, the description is as follows:

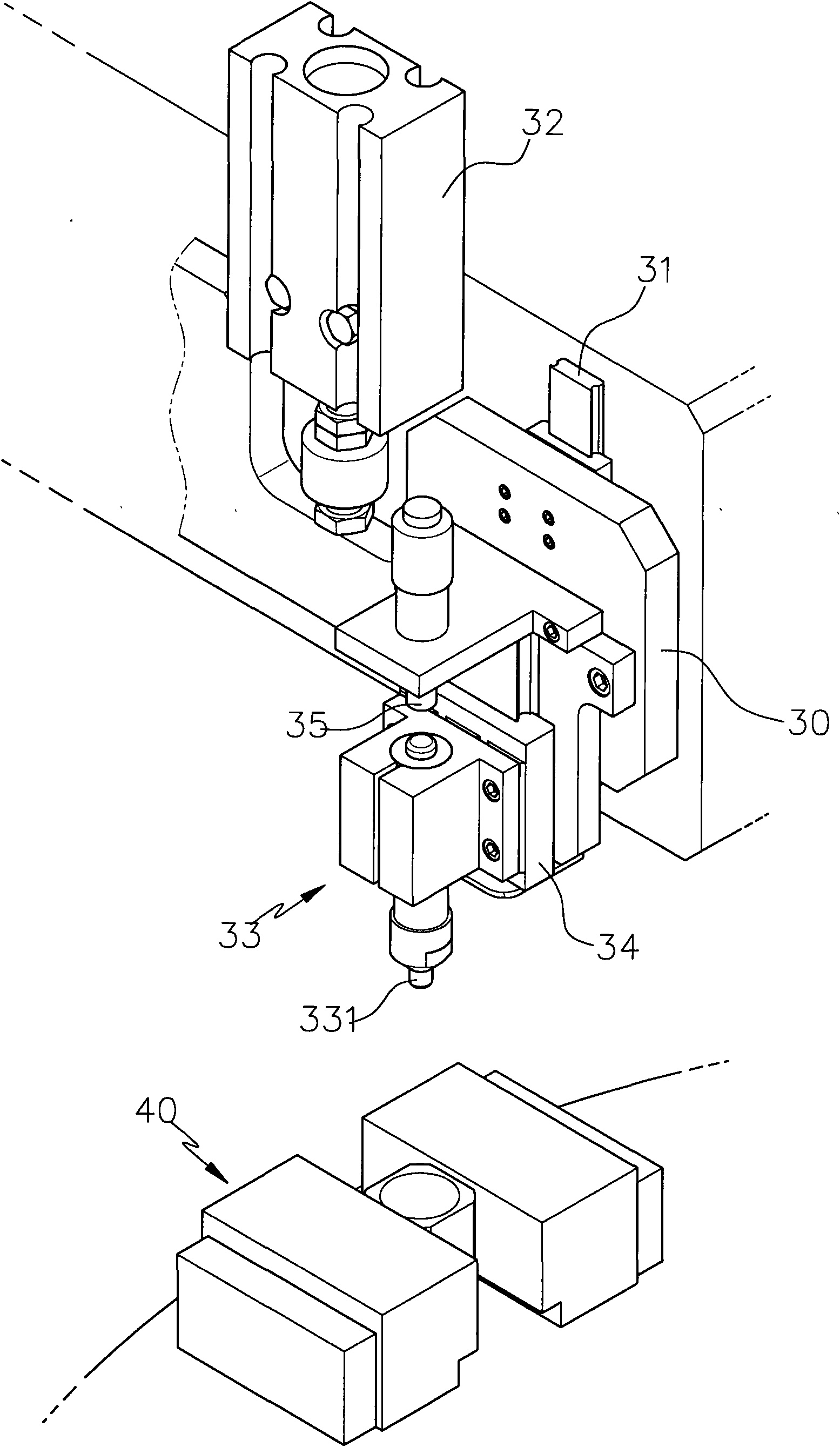

[0036] see image 3 , Figure 4 As shown, the present invention is provided with a sliding seat 30 connected with a lifting mechanism. The lift driving source 32 of the seat 30 is used to drive the sliding seat 30 to perform a lifting action, wherein the lifting driving source 32 can be a pressure cylinder, and a pressing group 33 is installed on the sliding seat 30, so the The pressing group 33 is provided with a pressing head 331 which can be used as a lens pick and place device, and a floating mechanism is arranged between the pressing group 33 and the sliding seat 30. The floating mechanism is to connect the pressing group 33 to another sliding rail group 34. It is slidably arranged on the sliding seat 30, so that the pressing head 331 of the pressing group 33 can move up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com