Pressing mechanism capable of accurately assembling lens

A pressing mechanism and lens technology, applied in installation, optics, instruments, etc., can solve problems such as low assembly efficiency and achieve the effect of improving assembly pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make your examiner further understand the present invention, hereby give a preferred embodiment, and cooperate with the drawings to describe in detail as follows:

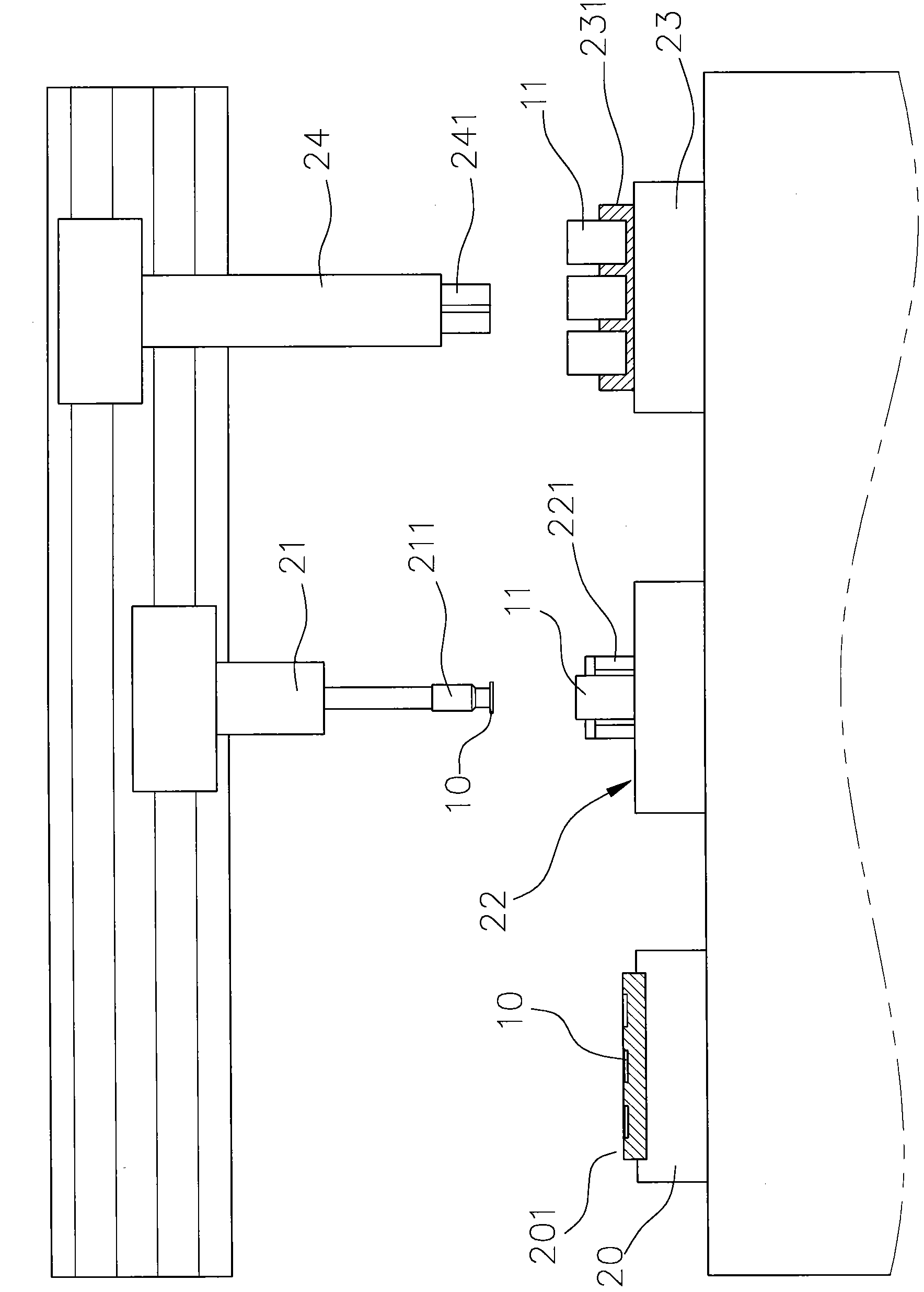

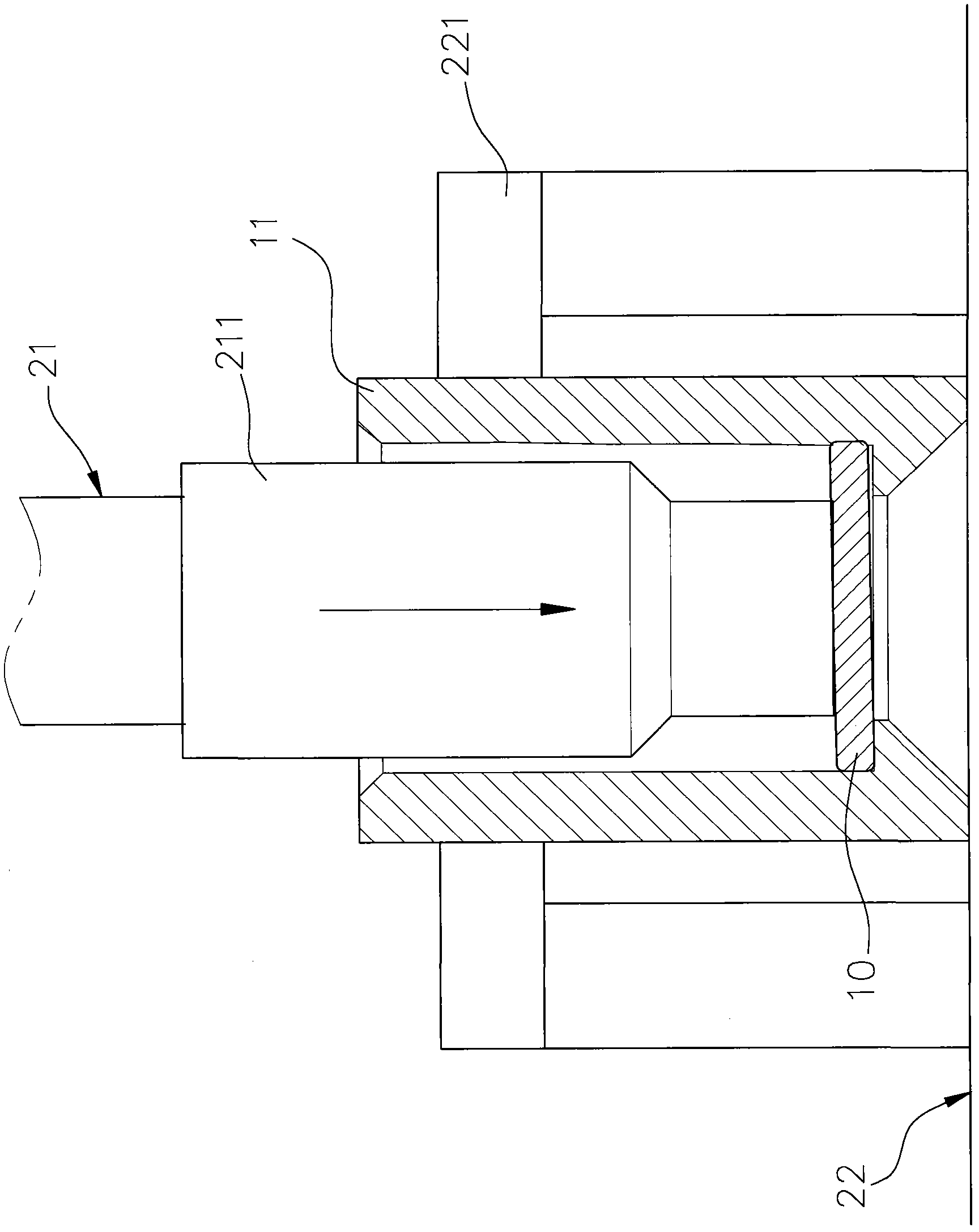

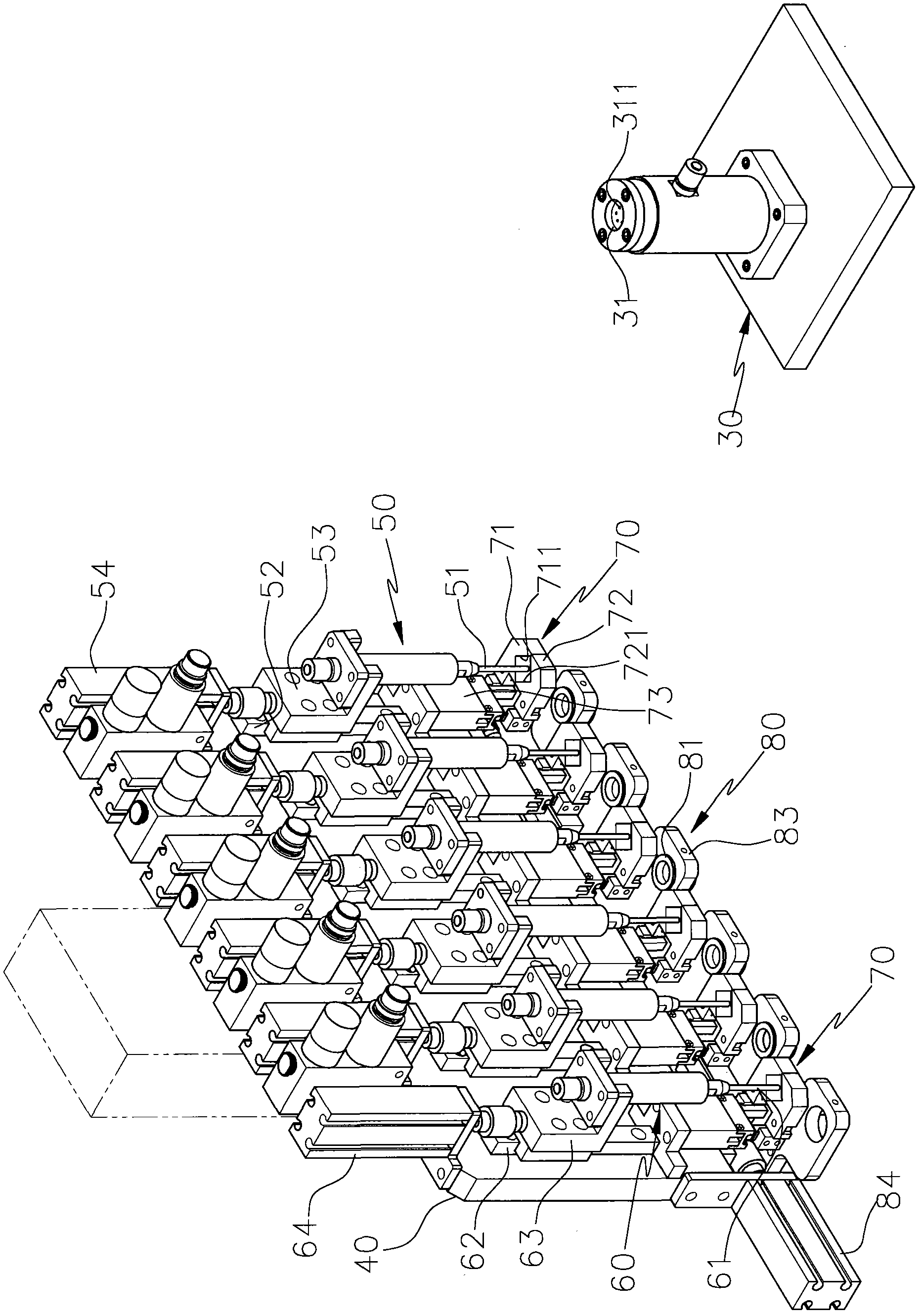

[0039] see image 3 , Figure 4As shown, the press-fit device of the present invention includes an assembly base 30, a board base 40, a lens pick-and-place device 50, a lens barrel pick-and-place device 60, a clamping group 70, and a press-fit jig 80; The housing part 31 is used to accommodate the lens barrel. There is a gap between the housing part 31 and the lens barrel, so that the lens barrel can be slightly displaced in the housing part 31, and the housing part 31 is connected with a negative Press the pipeline 311 for positioning the lens barrel; the plate base 40 is connected and installed on a transfer mechanism, so that the plate base 40 can be driven for three axial displacements; one side of the plate base 40 is equipped with Multiple sets of lens pick-and-place devices 50, the multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com