Self-protection type bottle cap assembly machine

An assembly machine and protective technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inaccurate screwing, inaccurate assembly, and low production efficiency, and achieve accurate assembly, high efficiency, and bottle Effect of cover quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

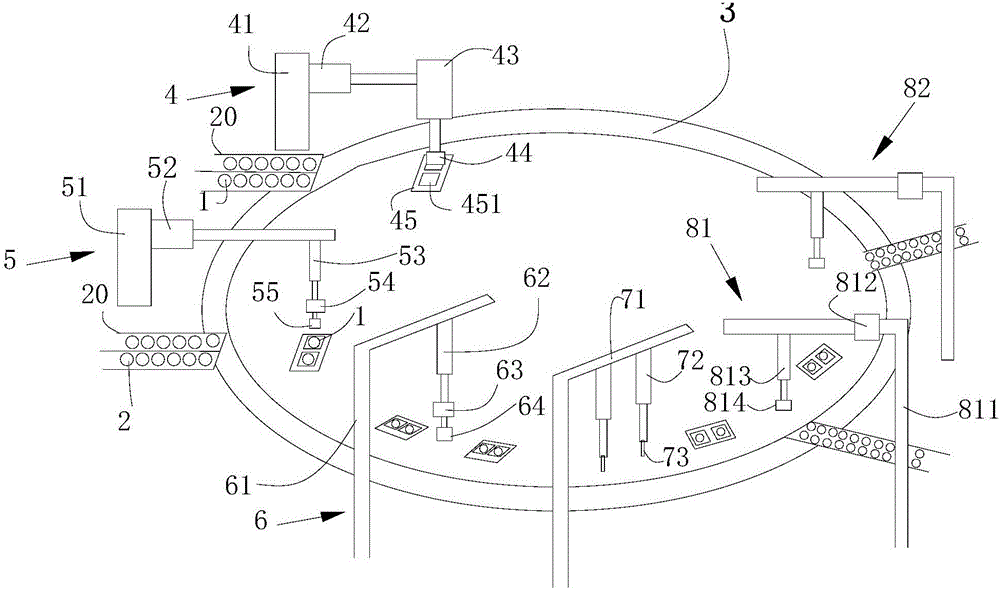

[0018] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

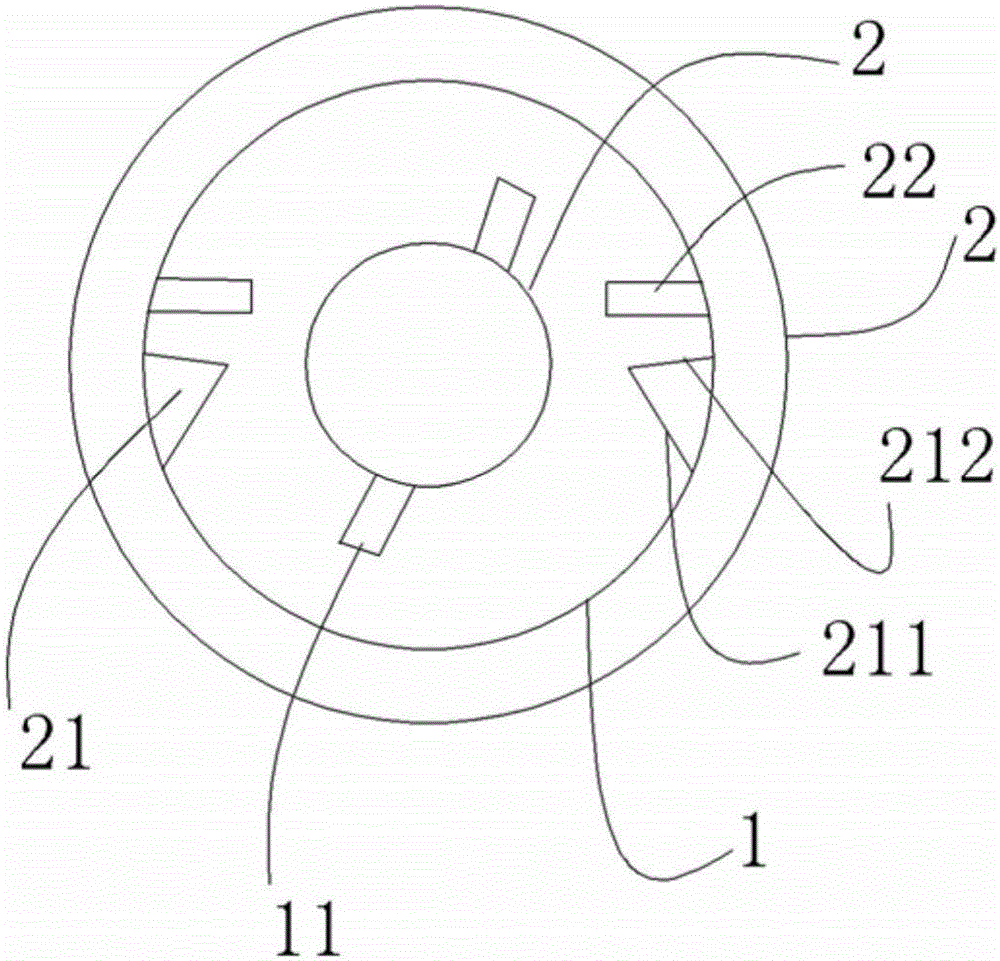

[0019] Bottle cap assembling device of the present invention is preferably suitable for such as figure 2 As shown in the bottle cap, the bottle cap includes a cap mouth 1 and an upper cover 2, and the inner circumference of the middle cap mouth 1 is provided with a plurality of limit protrusions 11 at intervals, wherein the inner surface of the upper cap 2 is spaced apart from each other. The protrusion is provided with at least one first protrusion 21, and the side of each first protrusion 21 is provided with a second protrusion 22 at intervals, and the distance between the first protrusion 21 and the second protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com