Product movable attachment and assembly mechanism

An assembly mechanism and attachment technology, which is applied to workpiece clamping devices, workbenches, manufacturing tools, etc., can solve problems such as leaving fingerprints, affecting product quality, and not being able to touch products, achieving rapid assembly and a wide range of applications , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

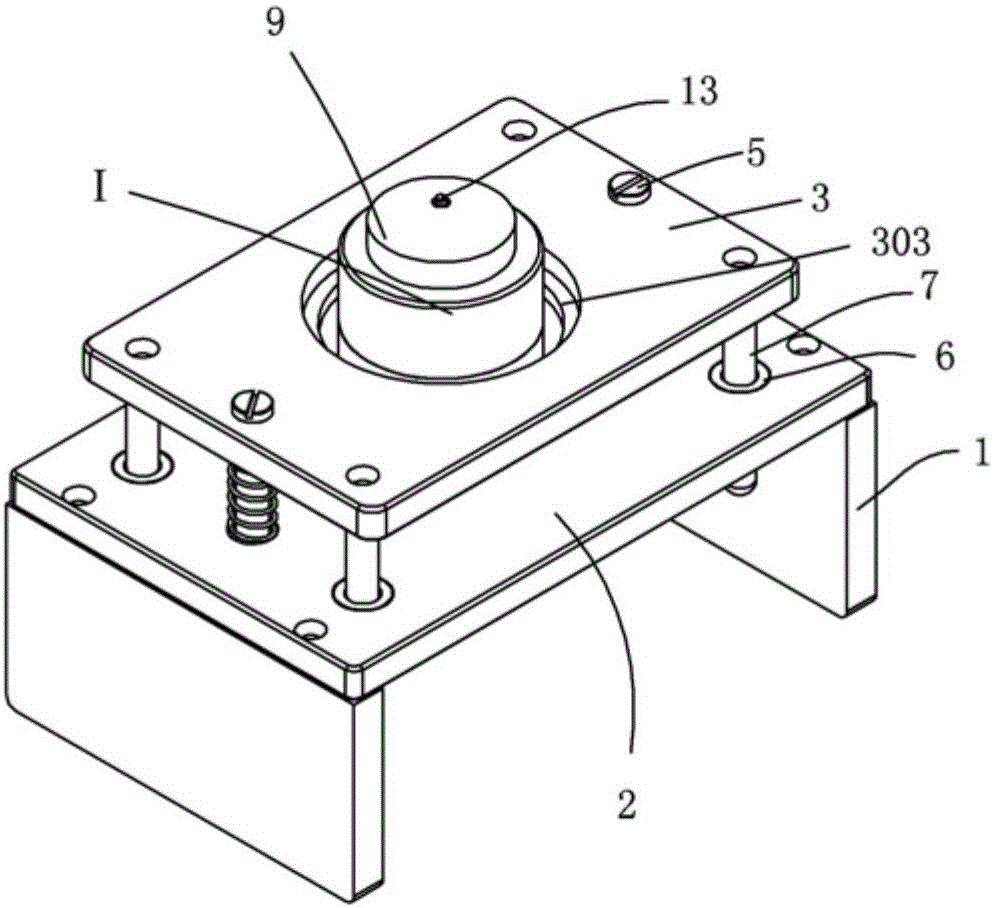

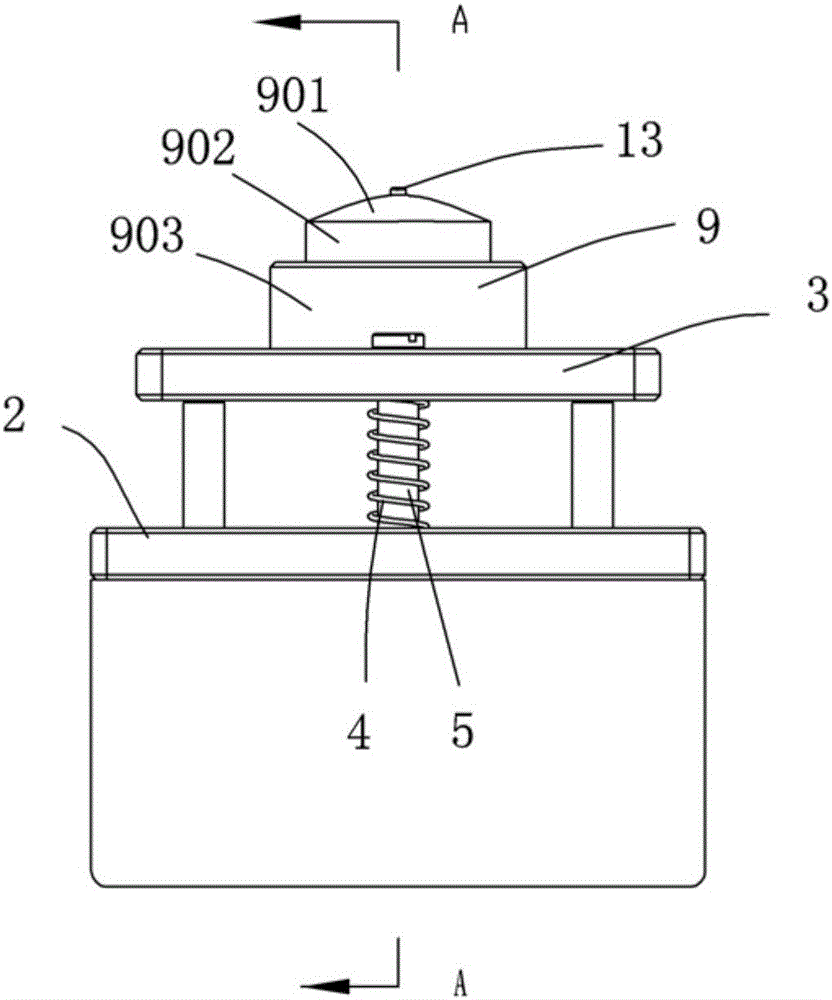

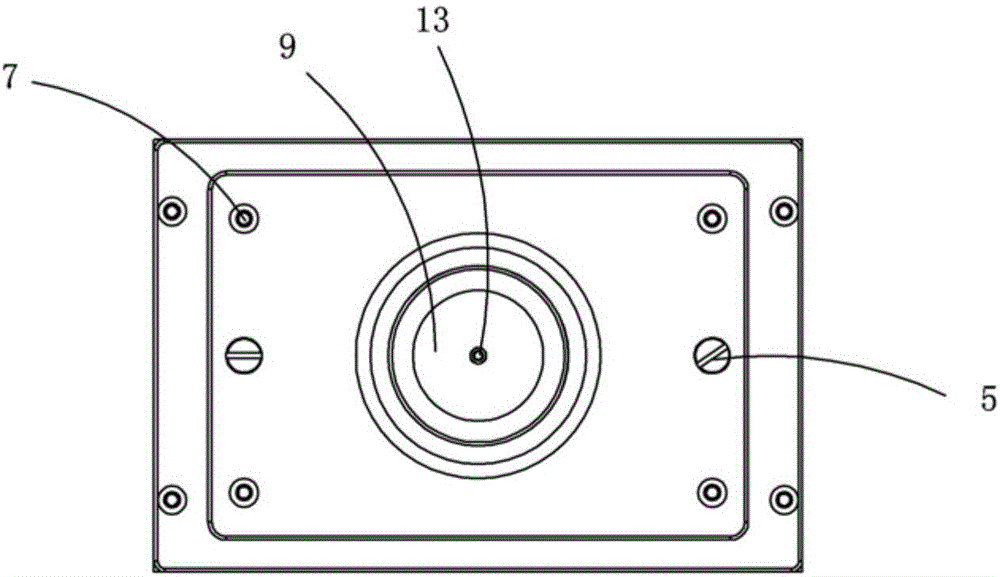

[0023] Examples, see attached Figure 1-6 , a product activity attachment assembly mechanism, including a fixed mounting plate 2 mounted on a support plate 1, the support plate has two groups, the two groups of support plates have the same structure, and are symmetrically and vertically installed under the fixed mounting plate respectively. The mounting plate is a flat plate structure, and the fixed mounting plate is installed horizontally, and the two sets of support plates are installed vertically. Fixing the support plate on the manipulator or on the plane can make the present invention fixed as a whole, which is convenient for the operation of the mechanism.

[0024] The fixed mounting plate is equipped with a carrier floating plate 3 through a guide assembly, and the carrier floating plate and the fixed mounting plate are connected together by a contour screw 5 covered with an elastic member a4. For products that need to be attached and assembled, in this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com