Optical fiber connector

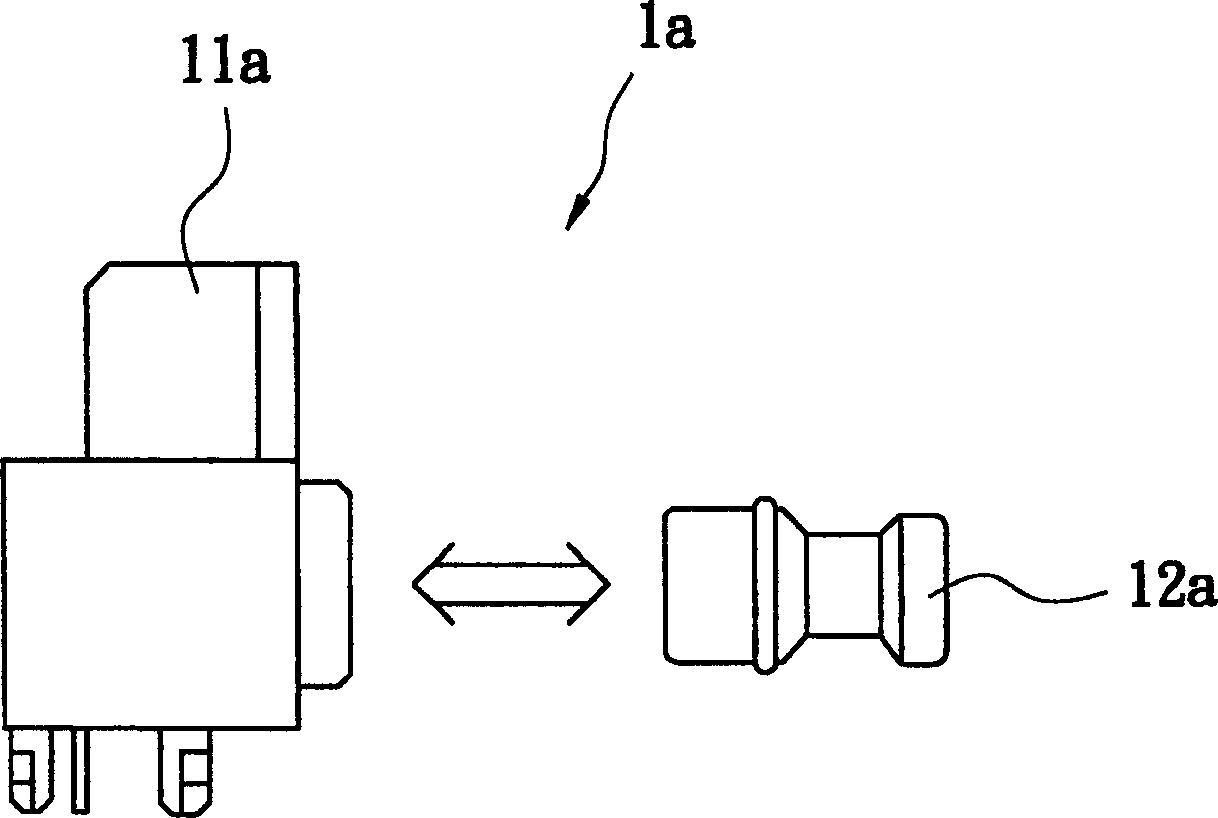

A technology of optical fiber connectors and optical fiber joints, applied in the coupling of optical waveguides, etc., can solve the problems of inability to achieve optical coupling of optical components, formation of guide groove extension, and insertion of optical fiber joints 6a, so as to improve the efficiency of assembly and testing, and strengthen the control system. Accurate, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

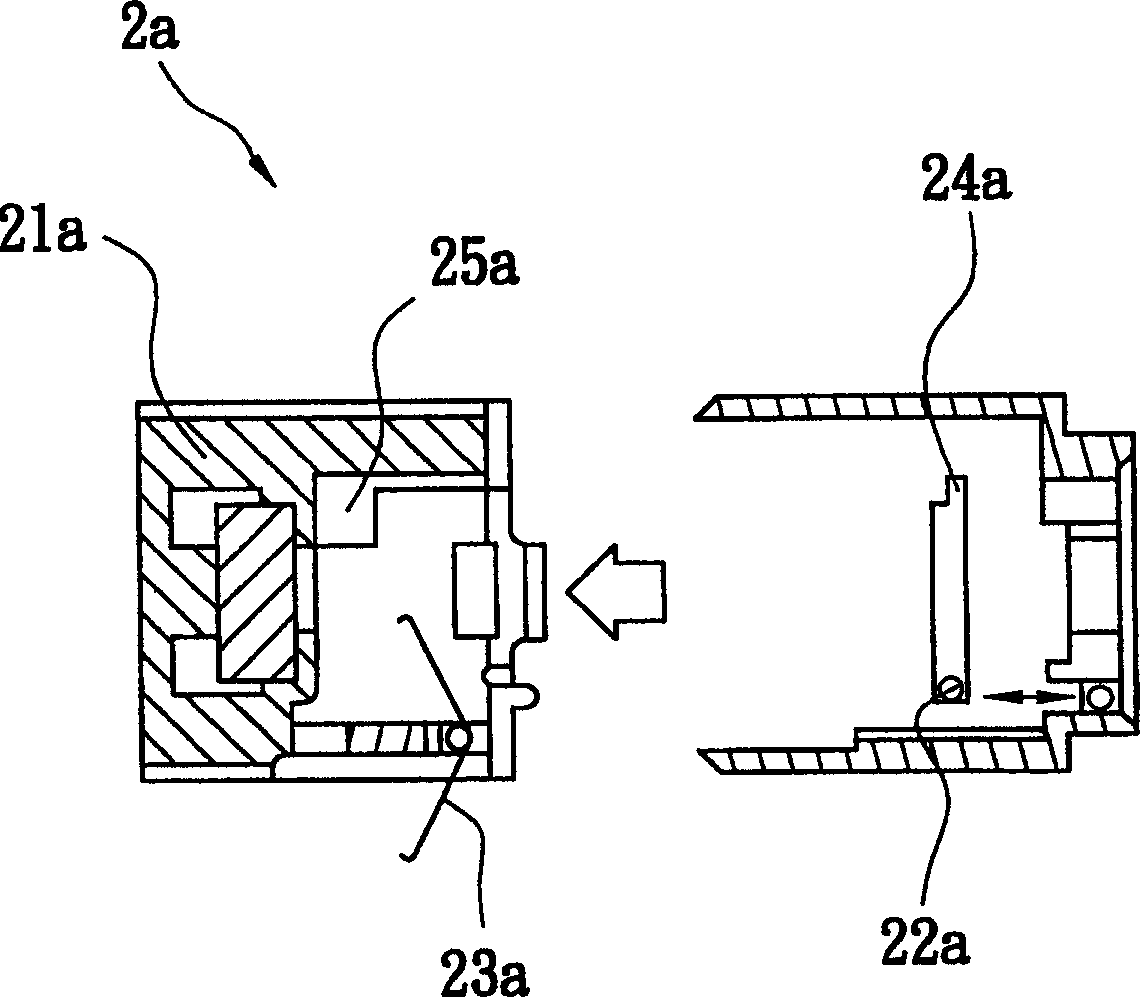

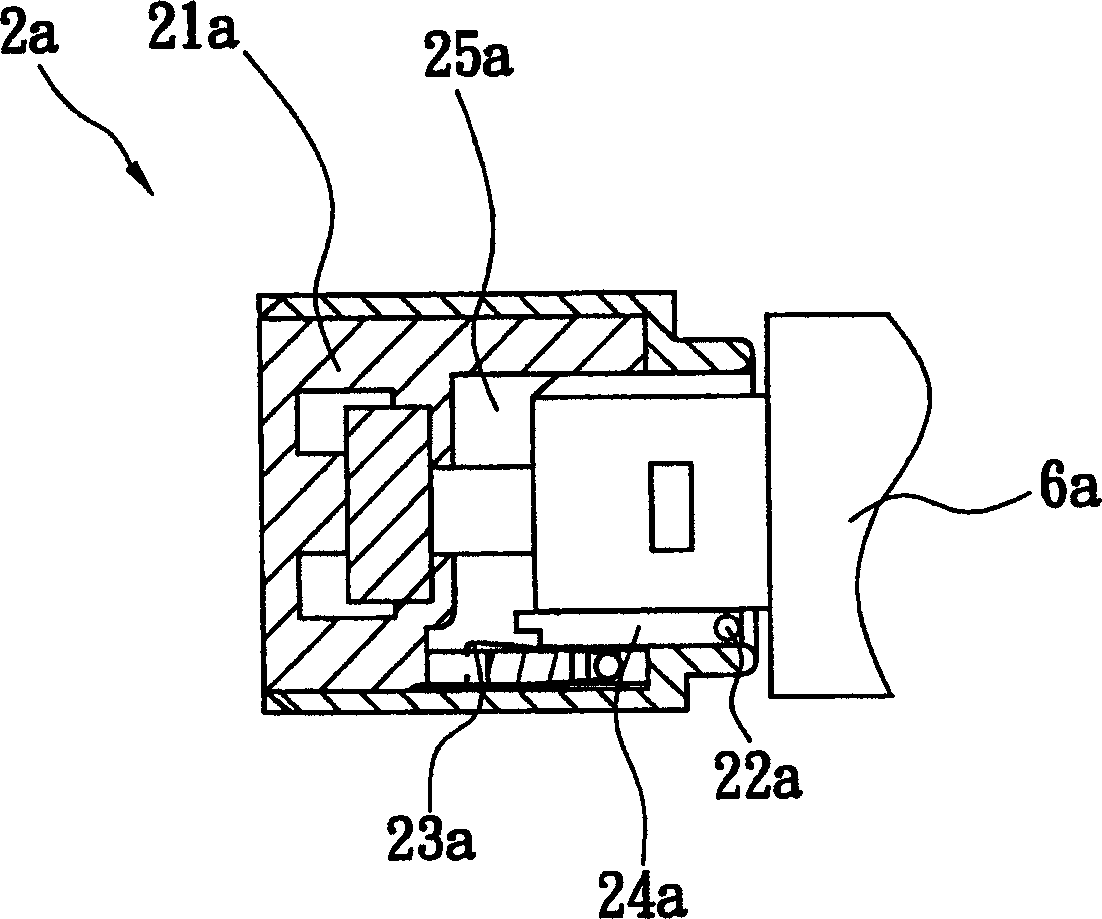

[0055] The present invention provides an optical fiber connector, which uses a U-shaped cover to cover the main body, and inserts the left and right side plates of the U-shaped cover with the card slots provided on the upper and lower edges of the main body. The type cover has a socket portion extending downwards from its top edge to integrally form a dustproof cover, and the two side plates have abutting surfaces that closely fit the card slot along the upper and lower edges; thereby, the main body and the The cover can be combined into an optical fiber connector with the dustproof cover. Its structure is simple and strong, and it is convenient to use and test. It can improve the efficiency of assembly and testing, reduce the cost, and avoid the assembly steps caused by the separate dustproof cover. Complicated to avoid the danger of children eating by mistake.

[0056] Please refer to Figure 6A to Figure 6C , the present invention provides an optical fiber connector 7 , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com