Spliced flower box

A splicing, flower box technology, applied in horticulture, botany equipment and methods, container cultivation, etc., can solve problems such as easy damage, printed patterns, and difficult splicing of flower boxes, achieving stable and reliable connection, convenient and accurate assembly, The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

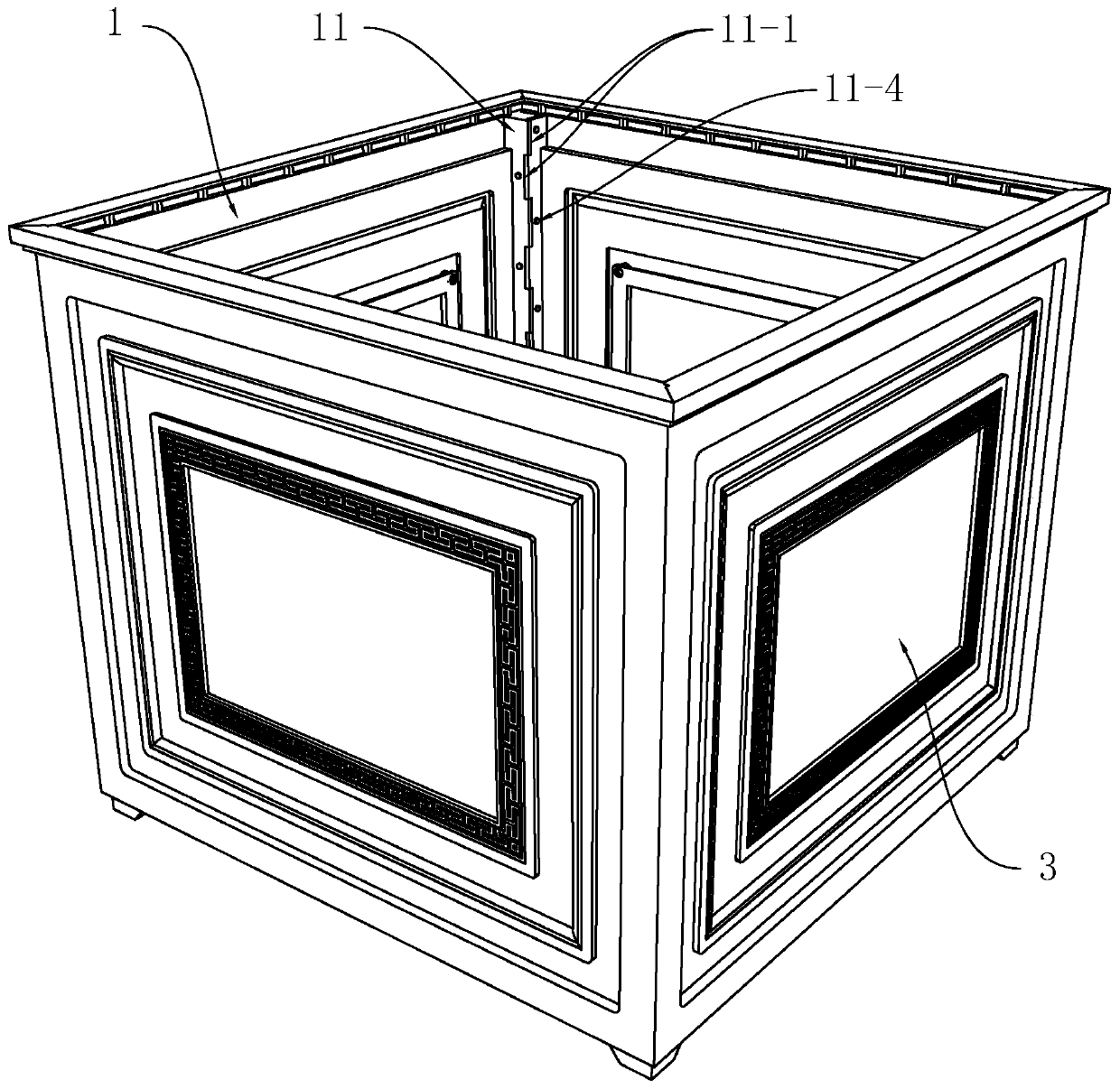

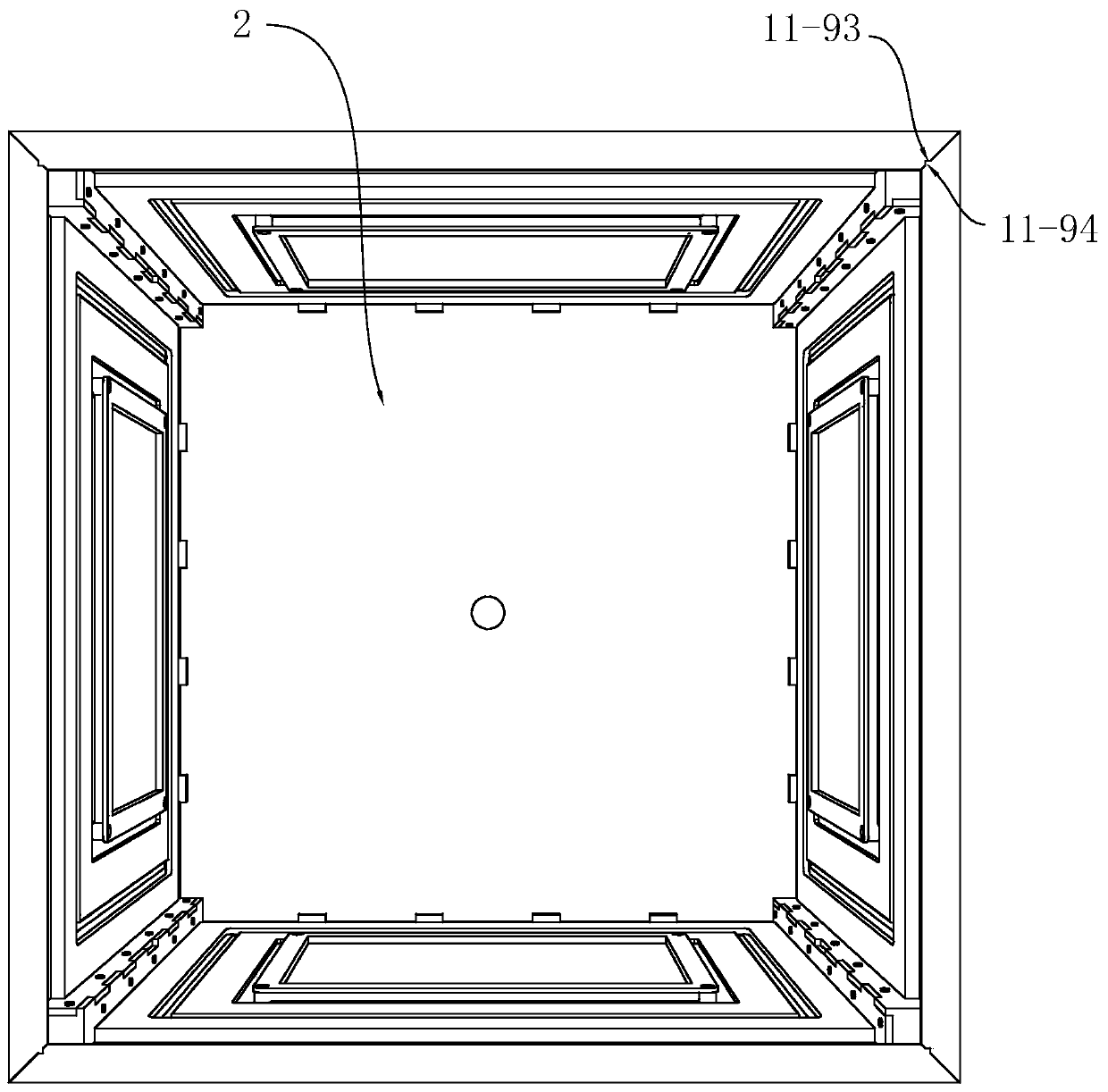

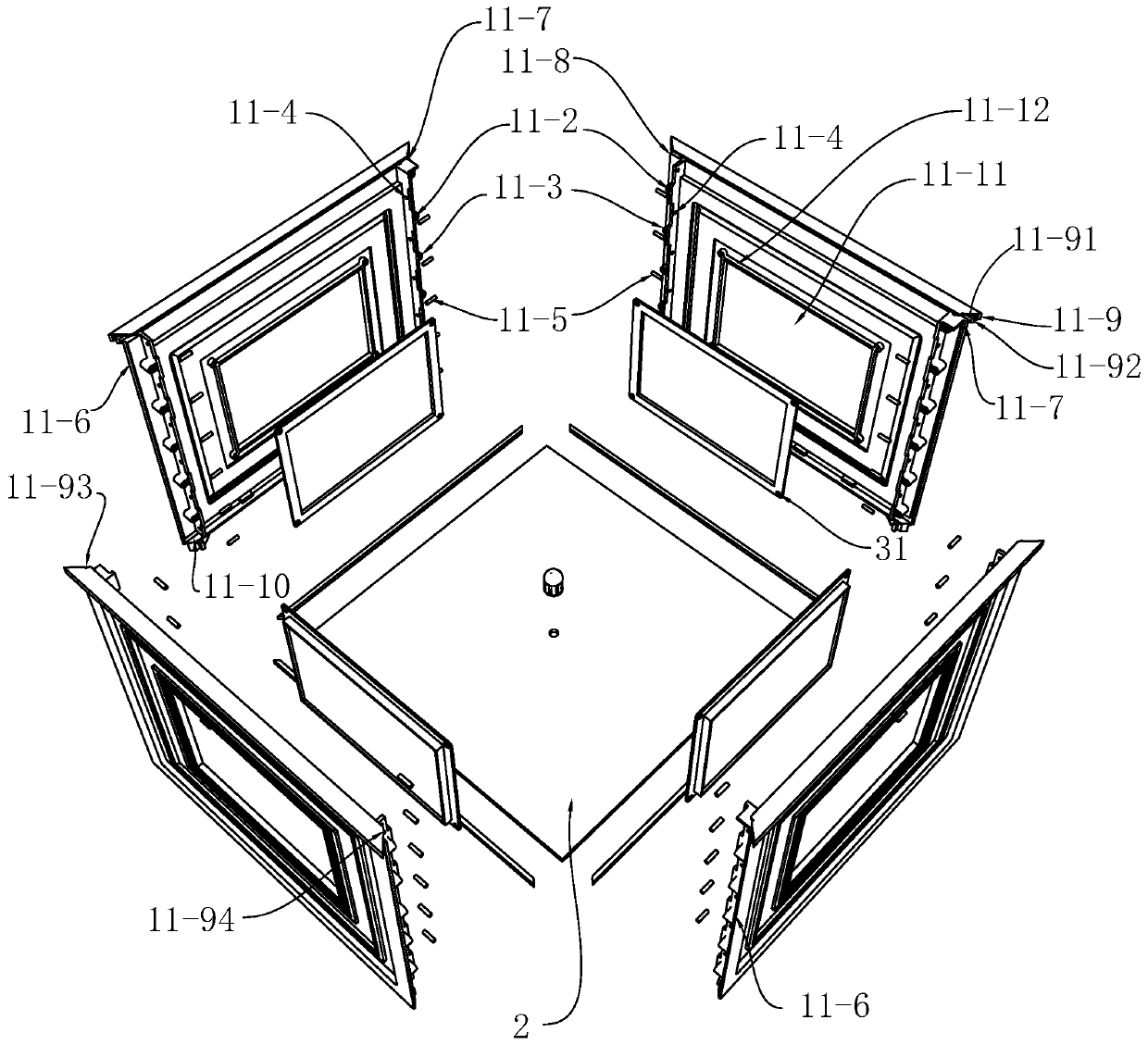

[0028] Example: such as Figure 1-7 As shown, the spliced flower box includes a side plate 1 and a bottom plate 2 formed by a polymer material mold. An integrally formed vertical connecting portion 11, the vertical connecting portion includes splicing edges 11-1 arranged at intervals of bayonet sockets, and hole columns 11-3 with pin holes 11-2 are arranged at intervals outside the splicing edges; adjacent side plates During splicing, the square-wave bayonet sockets on the splicing side are misplaced and inserted, and a bolt 11-5 passes through the through hole 11-4 on the splicing side and inserts into the pin hole 11-2 of the adjacent side plate.

[0029] The flower box involved in this technical solution adopts side panels and bottom panels made of polymer materials (such as glass fiber reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com