Method and device for highway safe transportation of super-long components of railway high-speed turnout

A transportation method and transportation device technology, applied in the direction of transportation and packaging, transportation objects, vehicles used for freight, etc., can solve the problems of shortening the construction period, construction costs, transportation turning difficulties, rail bending deformation, etc., to achieve good protection effect and conception Ingenious, avoid distortion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] A method for safely transporting super-long components of railway high-speed turnouts on roads, comprising the following steps:

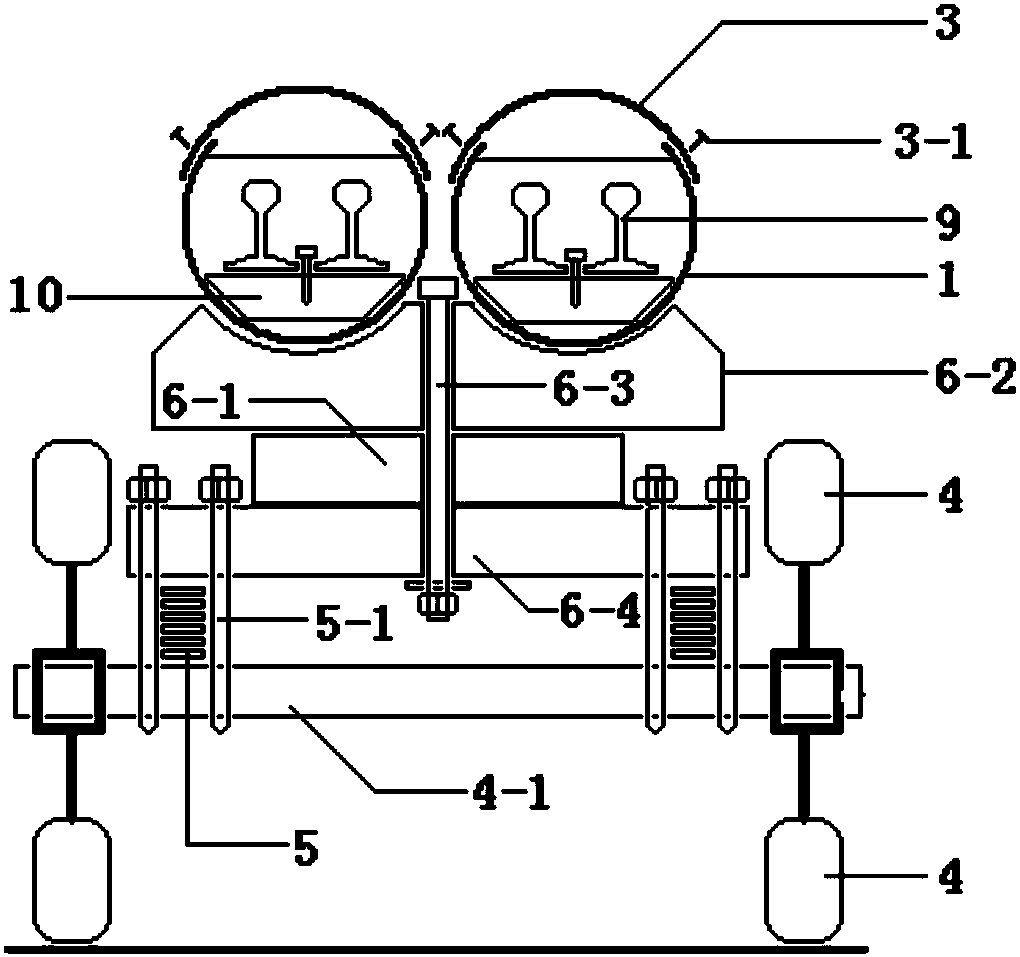

[0032] Step 1, fixing the two super-long turnout assemblies 9 on the skid 10 under the rail, and the skid 10 under the rail is provided with spikes for isolating the two super-long turnout assemblies 9;

[0033] Step 2, put the skids 10 under the rails and the turnout extra-long assembly 9 into the C-shaped steel channel 1, and fill the gap in the C-shaped steel channel 1 with sand;

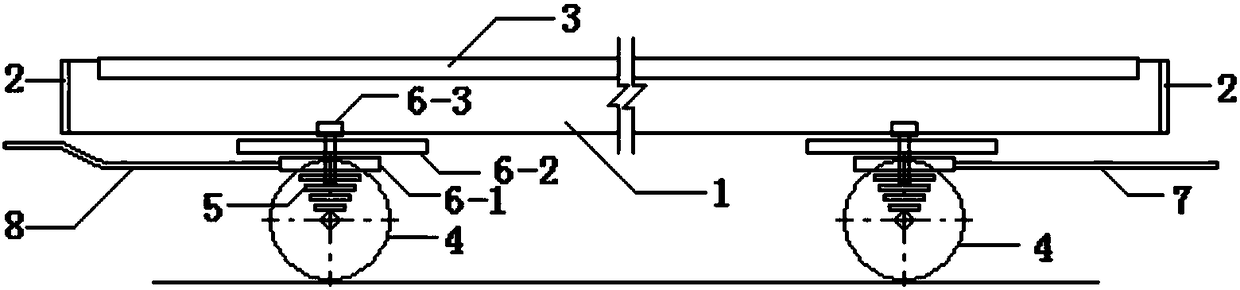

[0034] Step 3, fixing the ends of the steel plate 2 at both ends of the C-shaped steel channel 1, covering the arc-shaped steel cover plate 3 on the C-shaped steel channel 1, and fixing and connecting it with bolts to form a closed circular section;

[0035] Step 4: Fix the C-shaped steel channel 1 on the tractor with the shock-absorbing steel plate 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com