Mixing valve element automatic assembly line

A technology of mixing valve and assembly line, which is applied in the field of automatic assembly line of mixing valve core, can solve the problems of cumbersome installation work, consumption, and many manpower, and achieve the effects of reducing labor costs, increasing production efficiency, and increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings.

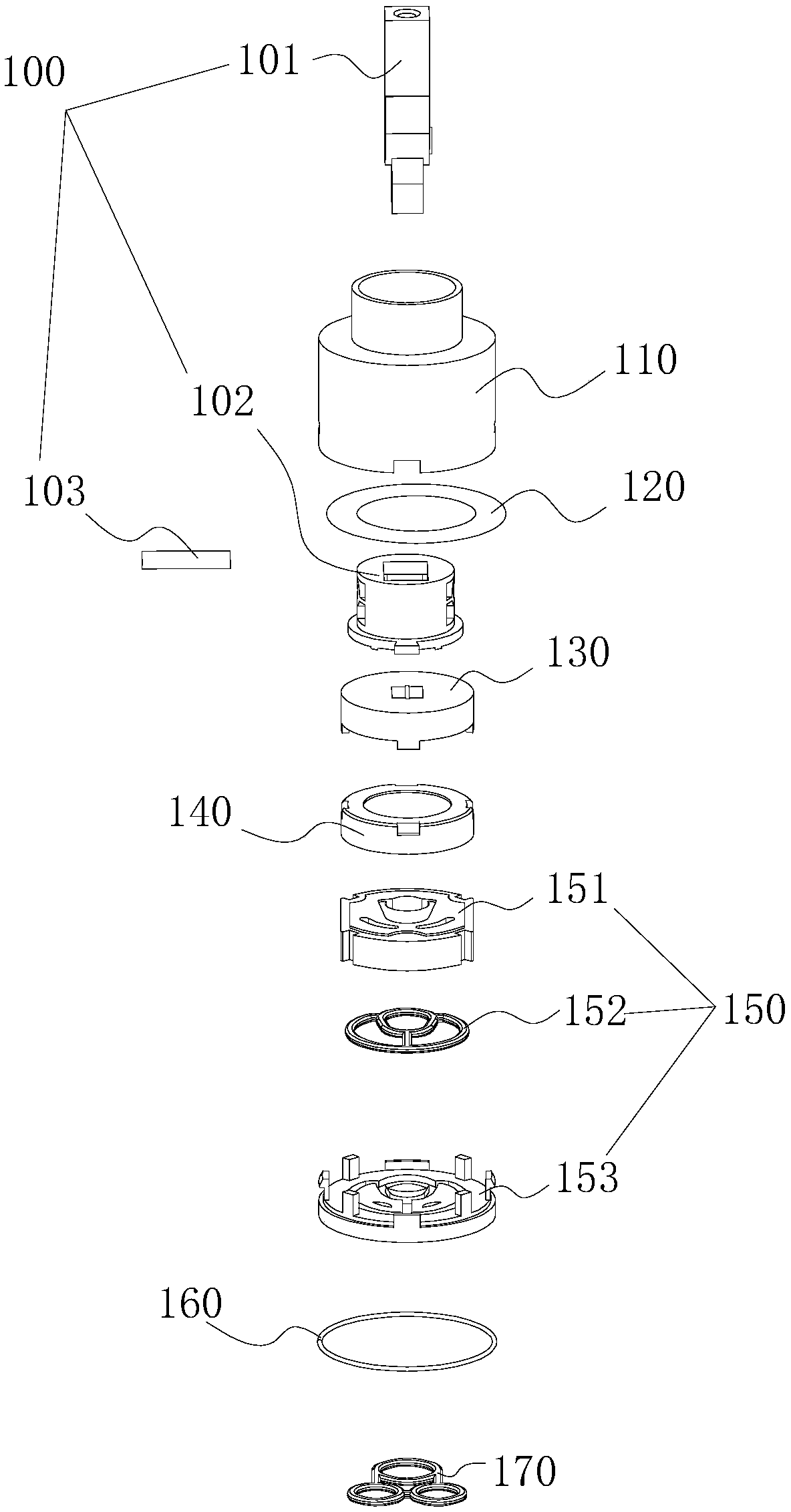

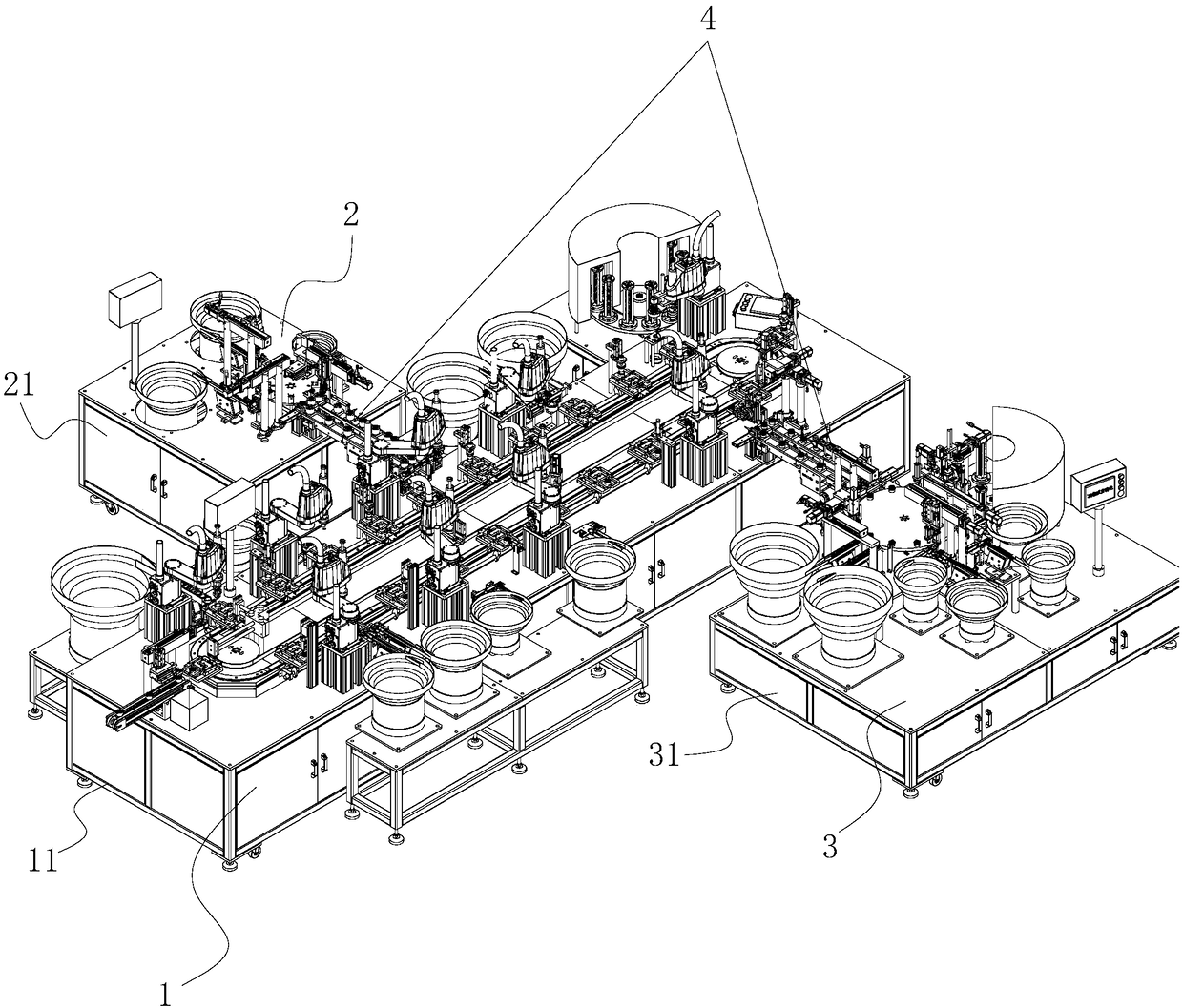

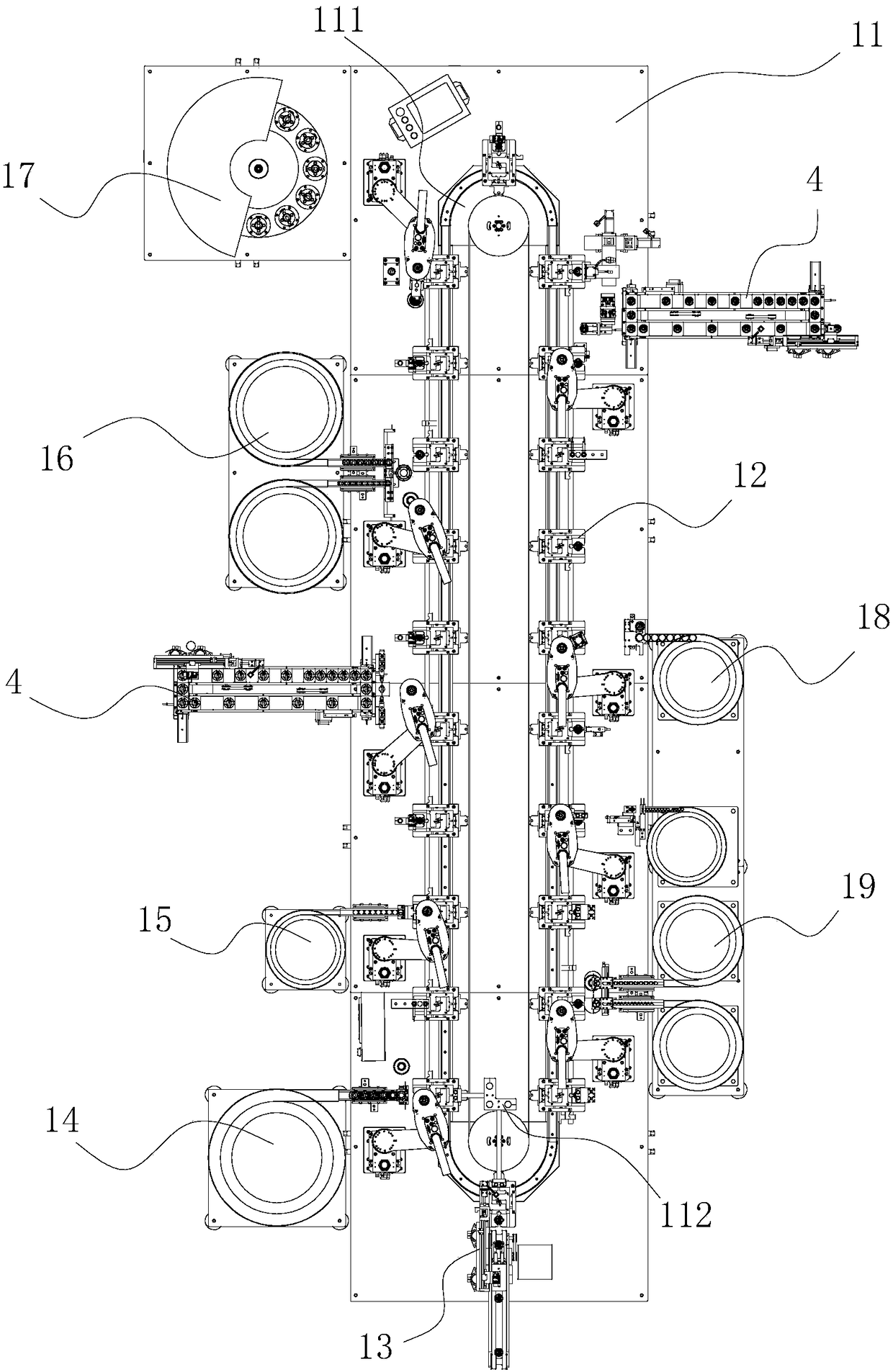

[0047] A hybrid spool automatic assembly line, such as figure 2 As shown, it includes the first auxiliary assembly line 2 for assembling the lever 101, the bracket 102 and the rotating shaft 103 together to form the valve stem assembly 100 in sequence, and the first auxiliary assembly line 2 for assembling the base 153, the inner O-ring 152 and the static ceramic plate 151 Assembled together in turn to form the second auxiliary assembly line 3 of the end cap assembly 150 and for the valve body 110, the gasket 120, the valve stem assembly 100, the dial 130, the moving ceramic piece 140, the end cap assembly 150, the large O The ring 160 and the outer O-ring 170 are assembled together in turn to form a complete assembly line 1 of the mixing valve core, wherein, between the first auxiliary assembly line 2 and the final assembly line 1 and the second auxiliary a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com