Method for improving bearing capacity of truss girder bridge through external prestressed tendons

An external prestressing and prestressing tendon technology, applied in the erection/assembly of bridges, bridges, bridge maintenance, etc., can solve the problems of less application, increase construction time and construction cost, and achieve convenient prefabrication and installation, easy design connection, The effect of shortening construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, the present invention is further described:

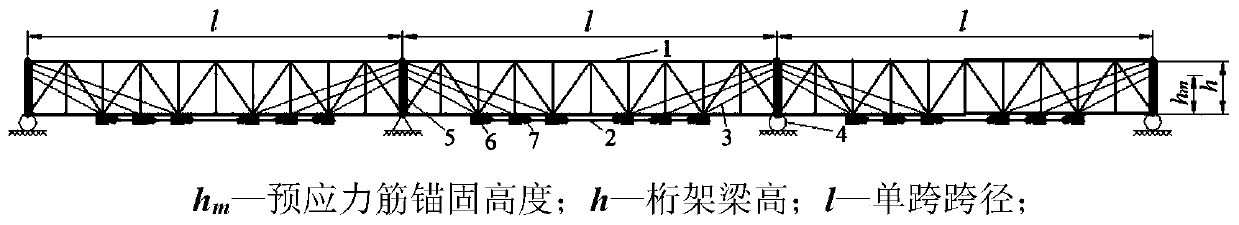

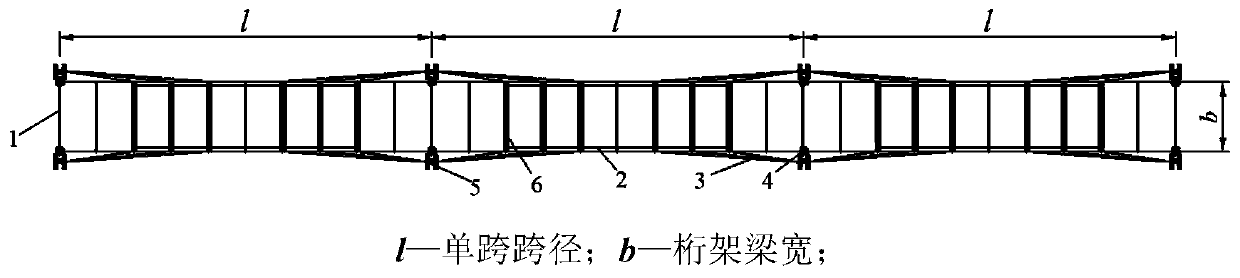

[0027] Such as Figure 1-Figure 4 As shown, a method of using external prestressed tendons to improve the bearing capacity of truss girder bridges. The specific implementation is as follows:

[0028] Step 1. After the construction of the substructure of the bridge is completed, the truss main girder 1 is erected and assembled. For bridges with large spans, temporary supports can be erected to reduce the mid-span bending moment of the main girder.

[0029] Step 2. After assembling the truss girder 1, install the prefabricated I-shaped side column 5 on the bridge pier, and bolts are used between the side column 5 and the bridge pier.

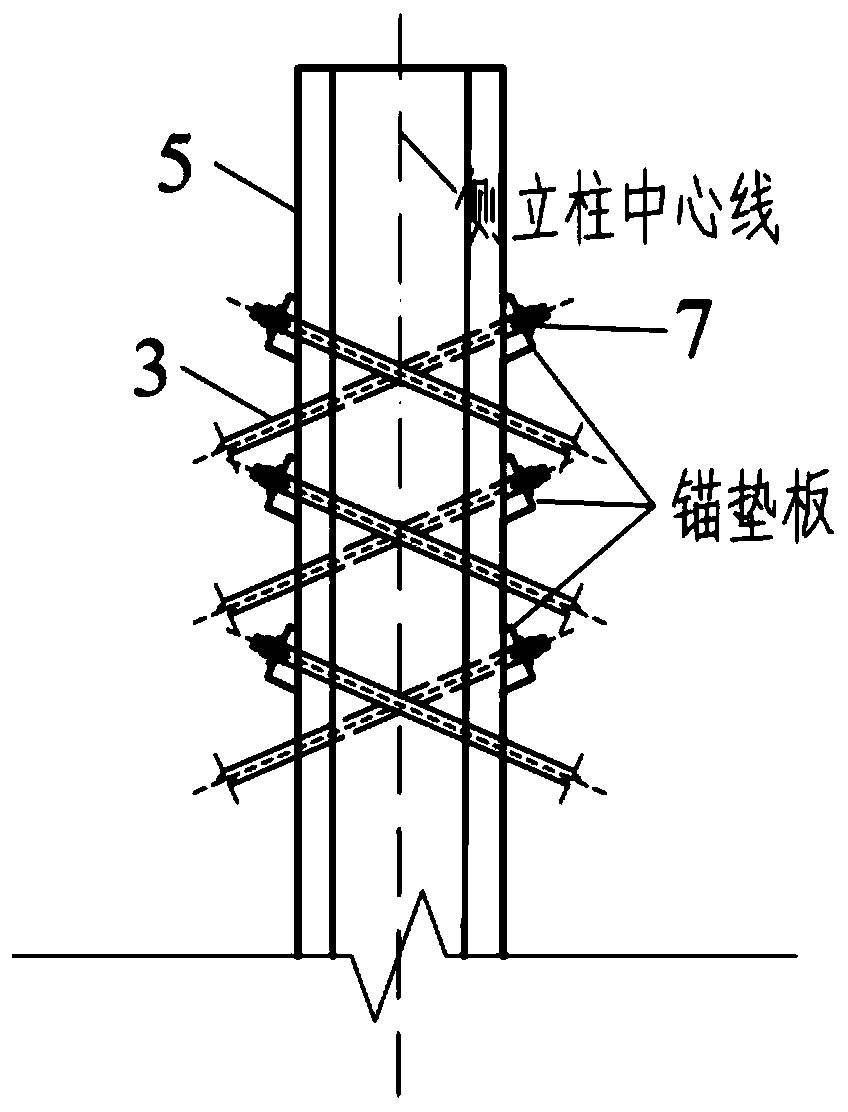

[0030] An inclined anchor backing plate is set at the corresponding position outside the flange plate of the I-shaped side column 5, such as image 3 Shown, in order to adapt to the tension direction of oblique prestressed tendon 3. Some stiffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com