Large-cantilever prestressed-cover-beam support device and construction method

A support device and prestressing technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of affecting the pouring quality of cover beams, large deformation, and small investment in steel consumption, so as to solve the contradiction of cast-in-place construction, The effect of safe construction and less steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

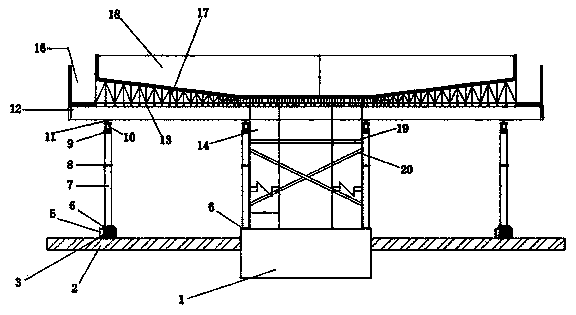

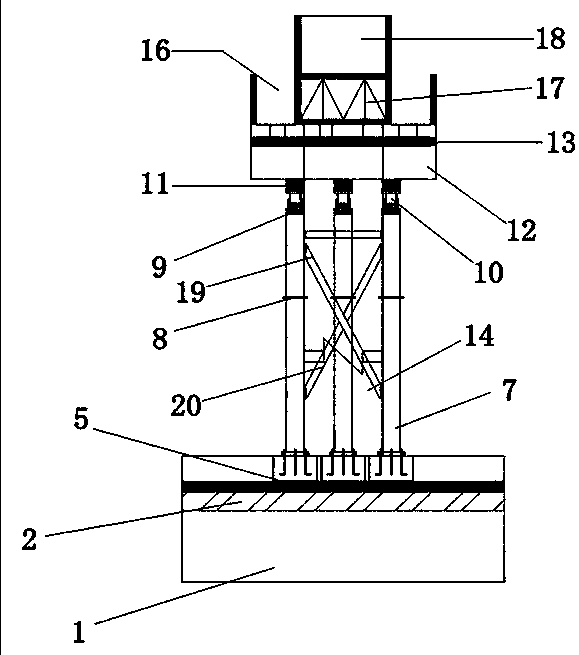

[0026] Such as figure 1 , 2 As shown, a large cantilever prestressed cover beam support device includes a middle support column supported on the cantilever root of the cover beam 18, and the middle support column is symmetrically arranged on both sides of the cover beam 18 piers 14, and the bottom of the middle support column It is supported on the cap 1 where the pier column of the cover beam 18 is located; it also includes an end support column supported on the cantilever end of the cover beam 18, the bottom end of the end support column is supported on the ground by reinforced concrete 5, and the middle part The upper ends of the support column and the end support column support the load-bearing beam, and the load-bearing beam supports the slope adjustment truss beam 17, and the slope adjustment truss beam 17 supports the bottom mold of the cover beam 18 on the upper end. Vehicles can pass between the middle support pillar and the end support pillar. The middle support co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com