Method for cast-in-place of ferrocement panel by spliced net frame suspension template

A technology of steel wire mesh and cement board, which is applied in truss structure, processing of building materials, joists, etc., can solve the problems of not being able to meet the production requirements of steel wire mesh cement board on-site pouring, not much utilization, unfavorable transportation, etc., and achieve weight Lightweight, good heat insulation effect, good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] Due to the great difference between the prefabricated production process and the on-site production process, we can find out after analysis that if the steel mesh cement board given in the national standard GB / T16308-2008 wants to use the on-site production process, it is mainly subject to the following technical bottlenecks:

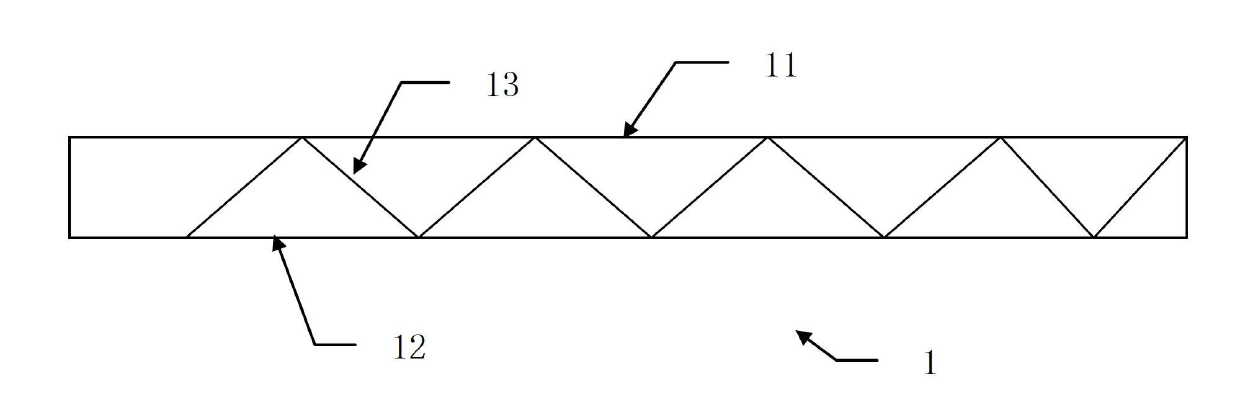

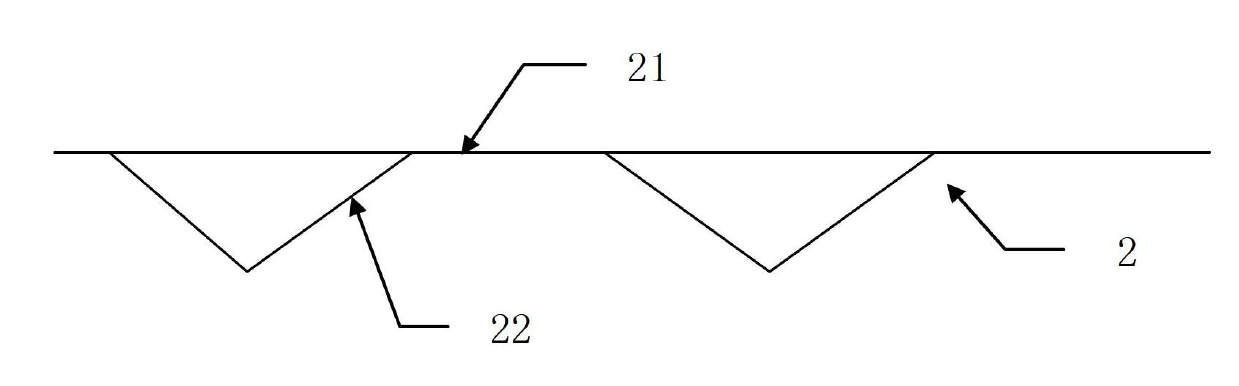

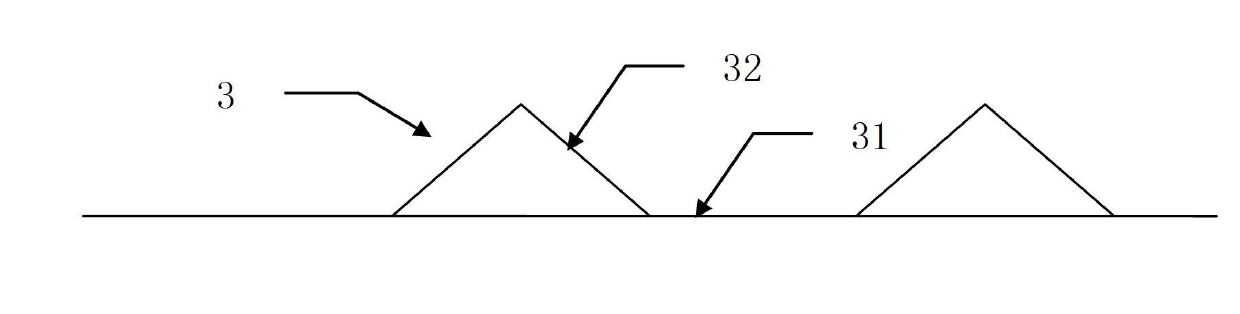

[0047] 1. Template making

[0048] The steel wire mesh cement board given in the national standard GB / T16308-2008 has high requirements for the formwork, which is determined by its own small cross-section characteristics. The accuracy requirements for the formwork are much higher than those made on site. Factory prefabrication uses steel molds and steam curing methods to increase the turnover rate of templates, which is difficult to achieve on site, even if it is done, the cost will be much higher than the cost of the board itse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com