Pulling and erecting method of truss girder

A truss girder, hauling technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of great influence of environmental factors, great influence by wind, increase operation danger, etc., so as to reduce aerial work and water work, The effect of shortening the construction period and being conducive to safe construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

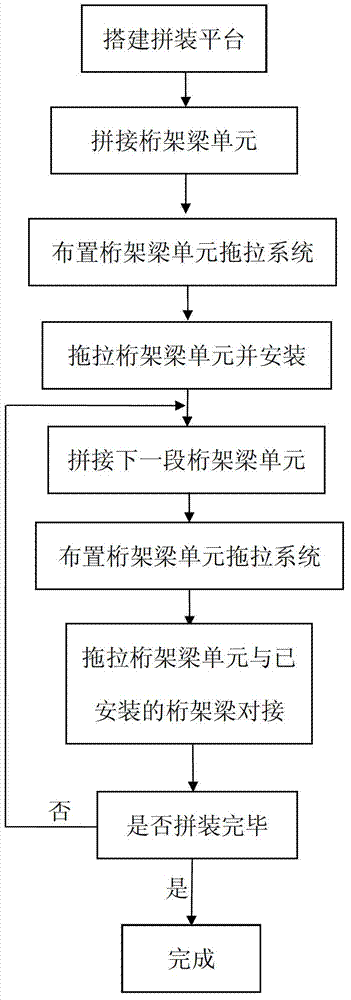

[0048] In this embodiment, the truss beam is divided into 11 truss beam units, such as figure 1 The drag-and-drag erection method of the truss girder shown is to divide the truss girder into several sections according to the shape of the bridge in the actual project, and ensure that the truss girder segments obtained after the truss girder segments are connected in turn meet the design requirements as a whole;

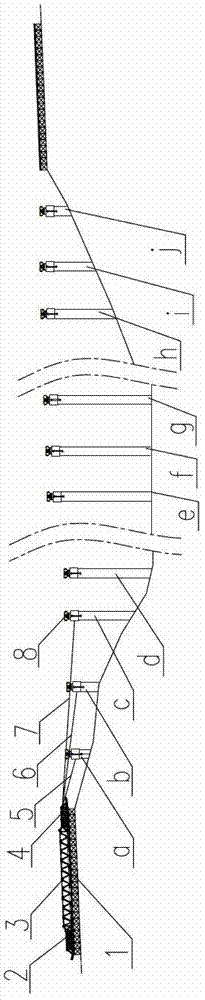

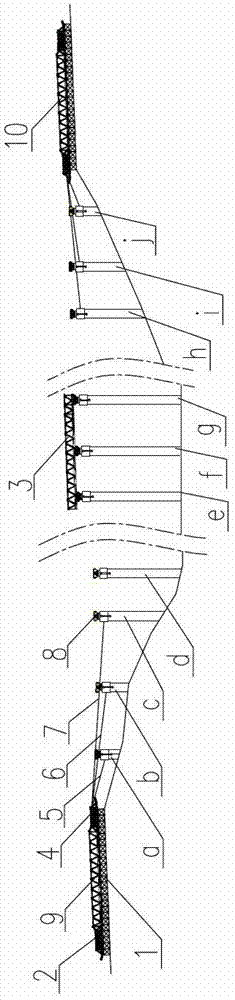

[0049] like figure 2 As shown, the assembly platform 1 of the truss beam unit is respectively built on the two banks corresponding to the bridge pier, and a slideway is set on the platform of the assembly platform 1, and the first section of the truss beam unit 3 is spliced on the assembly platform 1 according to the segmental requirements, and then Place it on the slideway, install the front guide beam 2 and the rear guide beam 4 at both ends of the truss beam unit 3, and then arrange a set of continuous jacks on each auxiliary truss beam unit, and arrange steel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com