Prestress aluminum-concrete combined truss beam and construction method thereof

A technology of combining trusses and truss girders, which is applied to truss girders, truss bridges, truss structures, etc., can solve problems that are difficult to think of, difficult to overcome prejudices, and no occurrences, and achieve the effects of light weight, shortened installation period, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

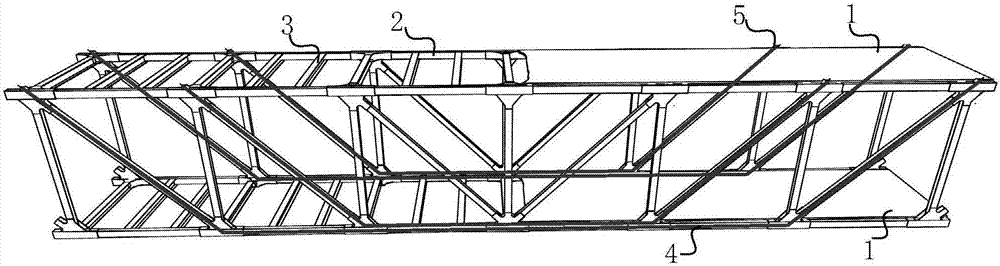

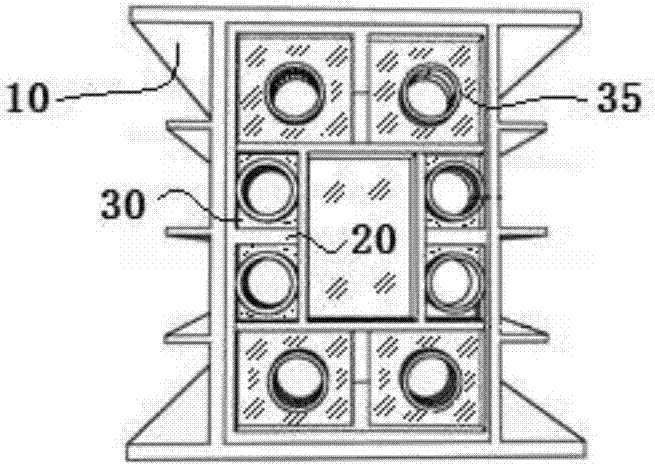

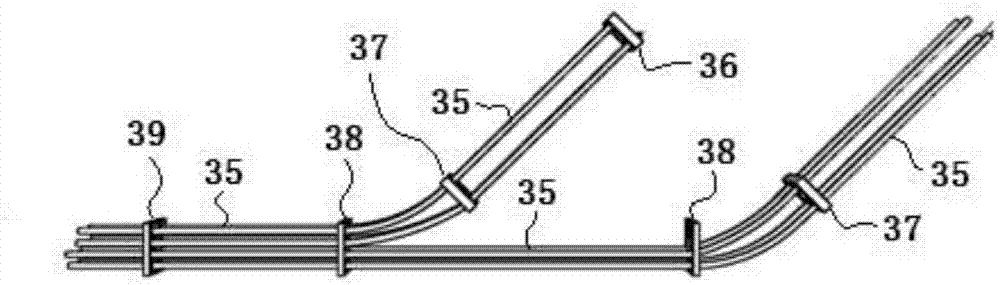

[0026] According to an embodiment of the present invention, such as Figure 1-5 As shown, the prestressed aluminum-concrete composite truss beam mainly includes: panel system 1, aluminum alloy main truss 2, cross brace 3, prestressed tendon 4, and prestressed tendon anchorage system 5, wherein the panel system 1 can be a steel panel or For concrete panels, etc., double-layer or single-layer panel structure system 1 can be set on the upper and lower main trusses 2 according to requirements, and form a reliable connection with the main truss 2, such as welding, to improve the integrity of the truss structure system; If the main truss 2 is designed as a box-shaped section or a tubular section, concrete is poured inside; if the main truss 2 is designed as an I-shaped or channel-shaped section, it is covered with concrete to form a composite structure, which can work together under external loads and can Improve the bending, shearing and torsional rigidity of the compression main t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com