Upside-down type supporting system of floor support plate

A support system and floor deck technology, applied in the direction of floor slabs, pillars, formwork/formwork/work frames, etc., can solve the problems of cumbersome binding of steel bars, occupation of vertical transportation time of cranes, long construction period and other problems, and achieve reduction Labor and equipment costs, reducing overall construction costs, and speeding up the overall construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

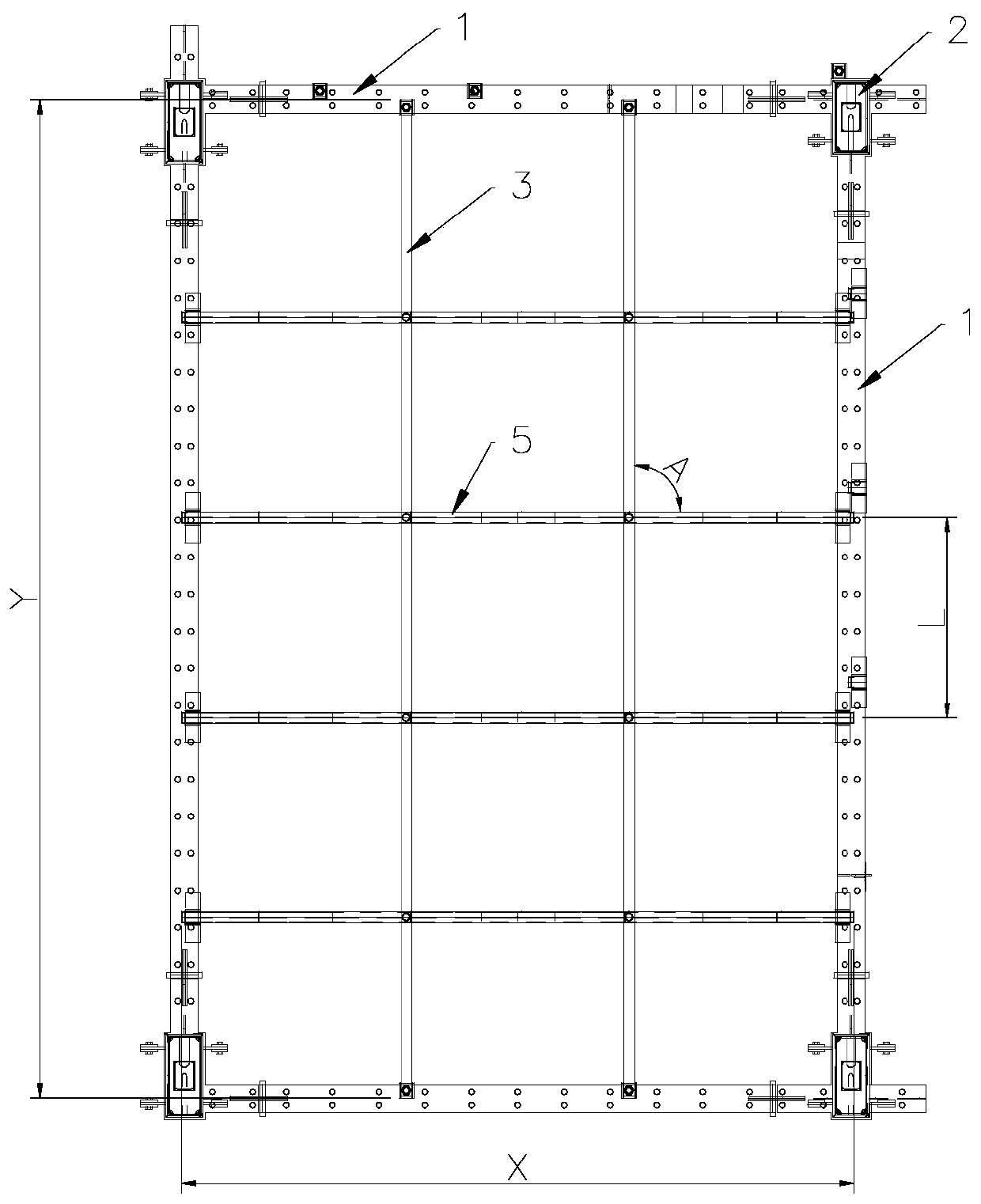

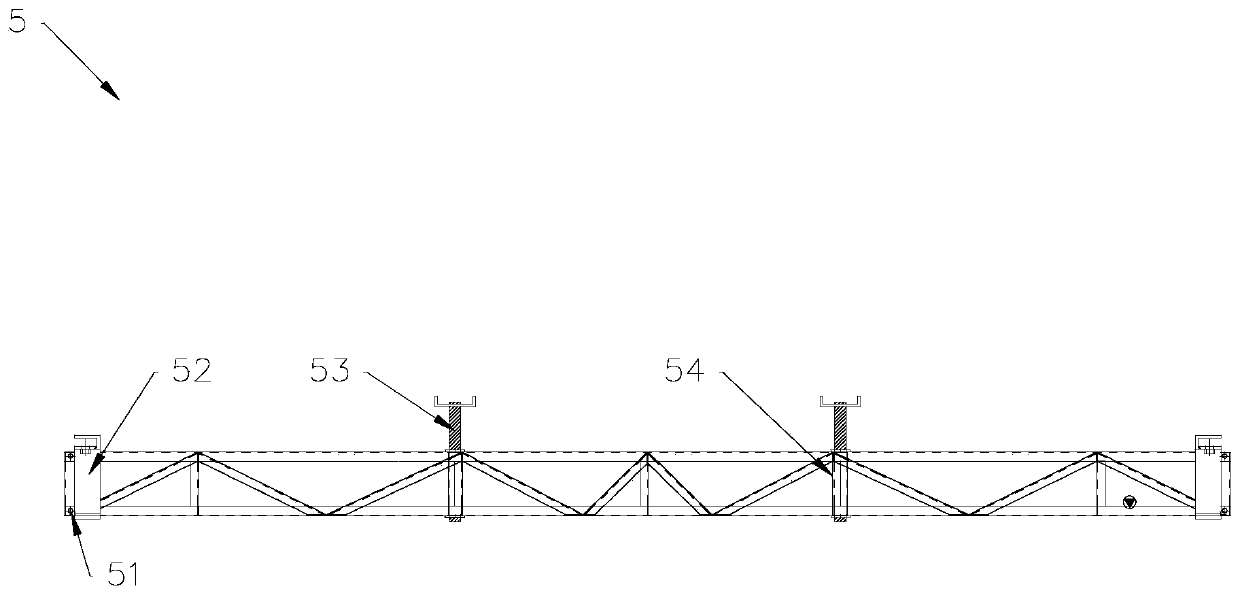

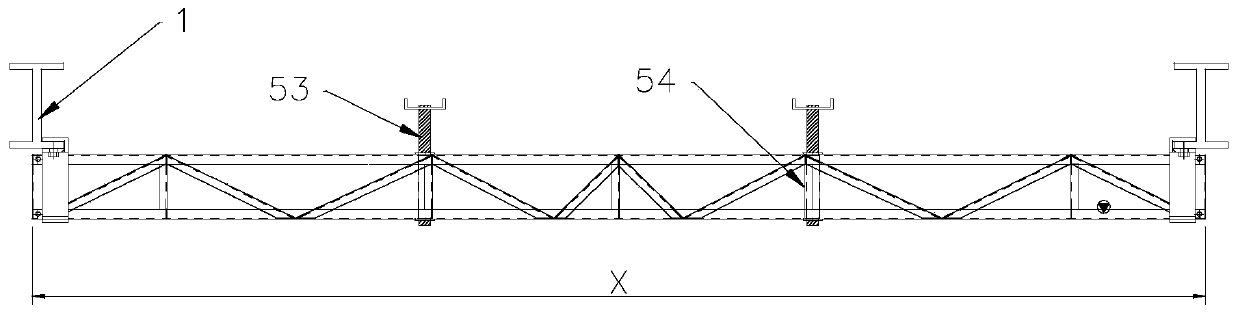

[0025] Such as Figure 1-Figure 7 As shown, an upside-down support system for a floor deck is assembled on a frame structure formed by connecting an I-shaped steel beam 1 and a steel column 2. The I-shaped steel beam 1 is a rigid structure in the prior art. It includes a rigid member composed of an upper flange, a web and a lower flange; the upside-down support system includes a plurality of truss beams 5 and a plurality of wooden corrugations 3 for supporting the floor deck, and the main body of the truss beam 5 It is welded by angle steel and is relatively light; the span Y of the corrugated 3 can be set according to needs; wherein figure 1 It is only a part in the present embodiment, and its length, width and area can be set according to the length, width and area of the residential building. Both ends of the truss beam 5 are provided with a bayonet hanger 52 for hanging on the lower flange, and the lower flange of the I-beam 1 is snapped into the bayonet hanger 52. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com