Aluminum alloy part surface paint removing treatment device and method

A technology for aluminum alloy parts and processing devices, which is applied in the field of paint removal treatment, can solve the problems of no application in the aircraft industry, and achieve the best paint removal effect, fast paint removal speed, and high paint removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

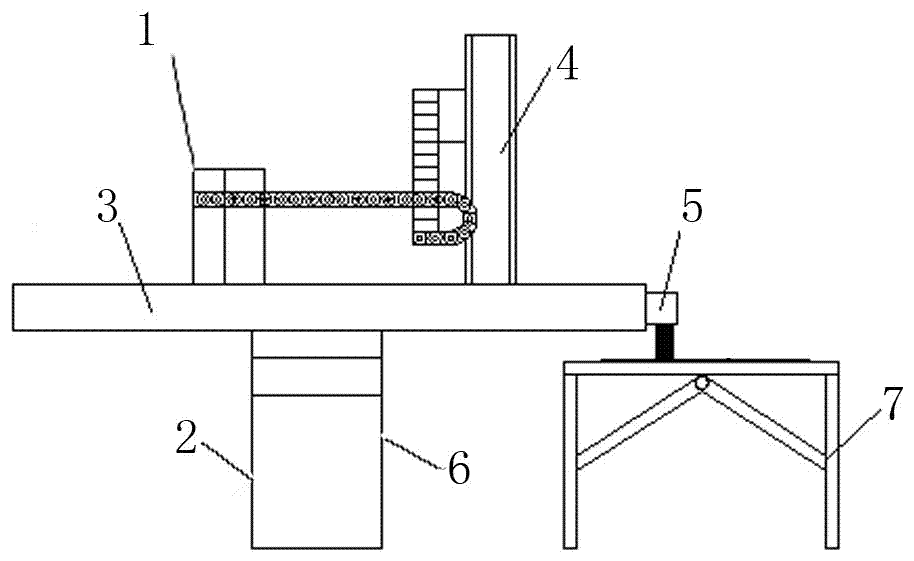

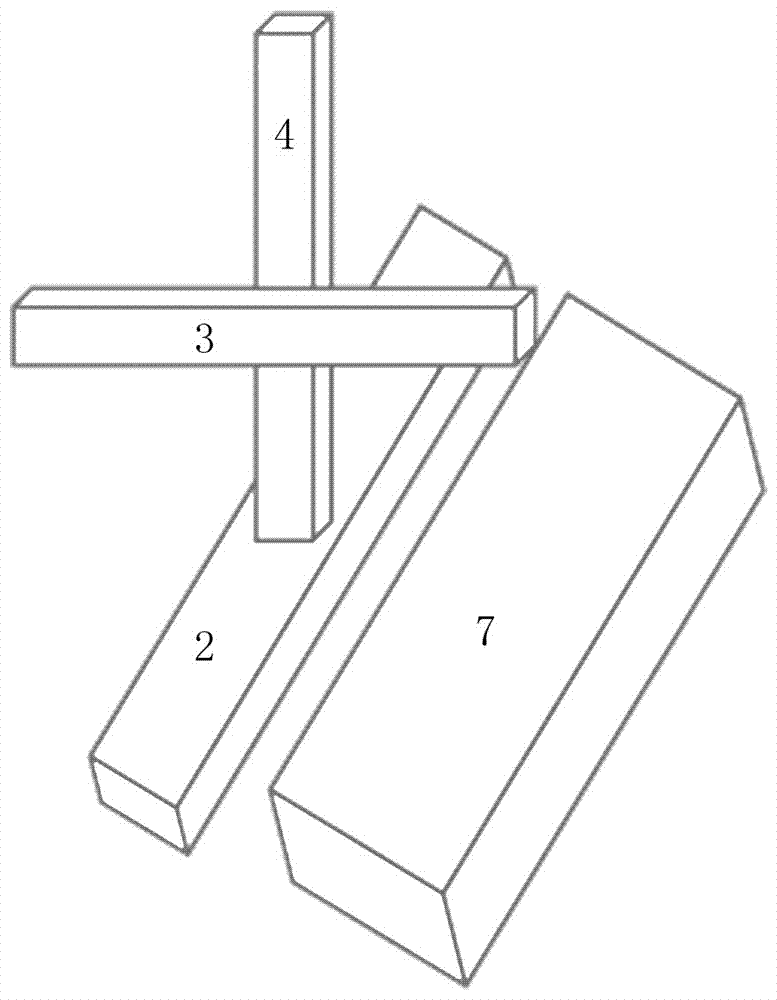

[0033] The surface paint removal treatment device for aluminum alloy parts of the present invention includes a workbench 7, a three-dimensional truss 6, a laser, a laser scanning device 5 and a control system 1, wherein the three-dimensional truss 6 includes an X-axis truss 2, a Y-axis truss 3 and a Z-axis truss. The axis truss 4; the workbench 7 is set parallel to the horizontal plane, and the X-axis truss 2 is set on the same level parallel to the workbench 7, wherein the X-axis truss 2 is located at the bottom of the entire three-dimensional truss 6, and its top is provided along the X-axis direction. Z-axis truss 4 slides in the chute on the top of X-axis truss 2; Y-axis truss 3 is connected to Z-axis truss 4 through a slider, wherein the slider slides along the Z-axis direction, and the Y-axis truss moves along the Y-axis The direction is connected with the sliding block; the laser is fixed on the Y-axis truss 3, and the laser scanning device 5 is fixed on the laser outlet...

Embodiment 2

[0041] This embodiment also includes a dust remover 3 connected to the control system 1, the dust remover 3 is provided with two air suction pipes, both of which are arranged on the Y-axis truss 3, and are respectively symmetrically arranged on the laser scanning device 5 The distance between the air suction port of the dust remover 3 and the focusing plane of the laser in the laser is 30-50mm. In this embodiment, when the laser is started, the control system 1 starts the dust remover, and the suction port of the dust remover moves with the laser, 30-50mm. This distance can effectively suck away the smoke and paint flake dust produced by laser paint removal in time, and can prevent The smoke and dust pollution field mirror absorbs the smoke and particles generated during the paint removal process simultaneously, and is filtered and collected by the dust collector to achieve pollution-free operation, thereby achieving the purpose of clean production and green manufacturing.

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1 or 2, except that this embodiment also includes a water-cooling device connected to the control system 1, the water-cooling device includes a refrigerator and a circulation pipe loop, and the circulation pipe loops are respectively sleeved External to the laser and control system 1.

[0044] In this embodiment, the circulation pipe circuit of the water cooling device is used to cool the laser and the control system 1 to avoid equipment damage due to excessive temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com