Device and method for improving surface quality of selective laser melting (SLM) forming piece through integrated double-type laser light

A technology for surface quality and molded parts, which is applied in the field of devices integrating dual-type lasers to improve the surface quality of SLM molded parts, can solve problems such as spheroidization and metal powder melting, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

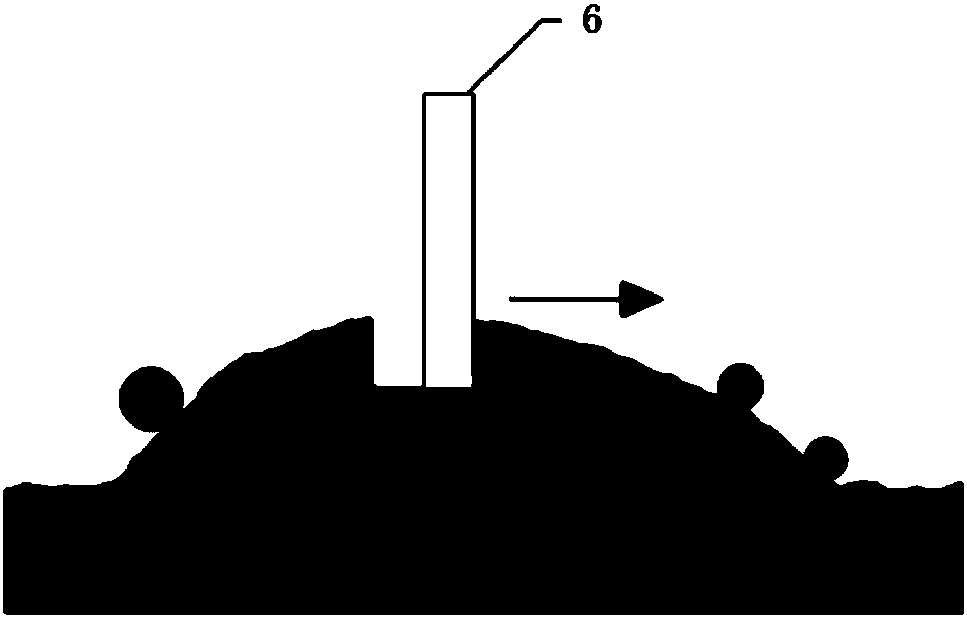

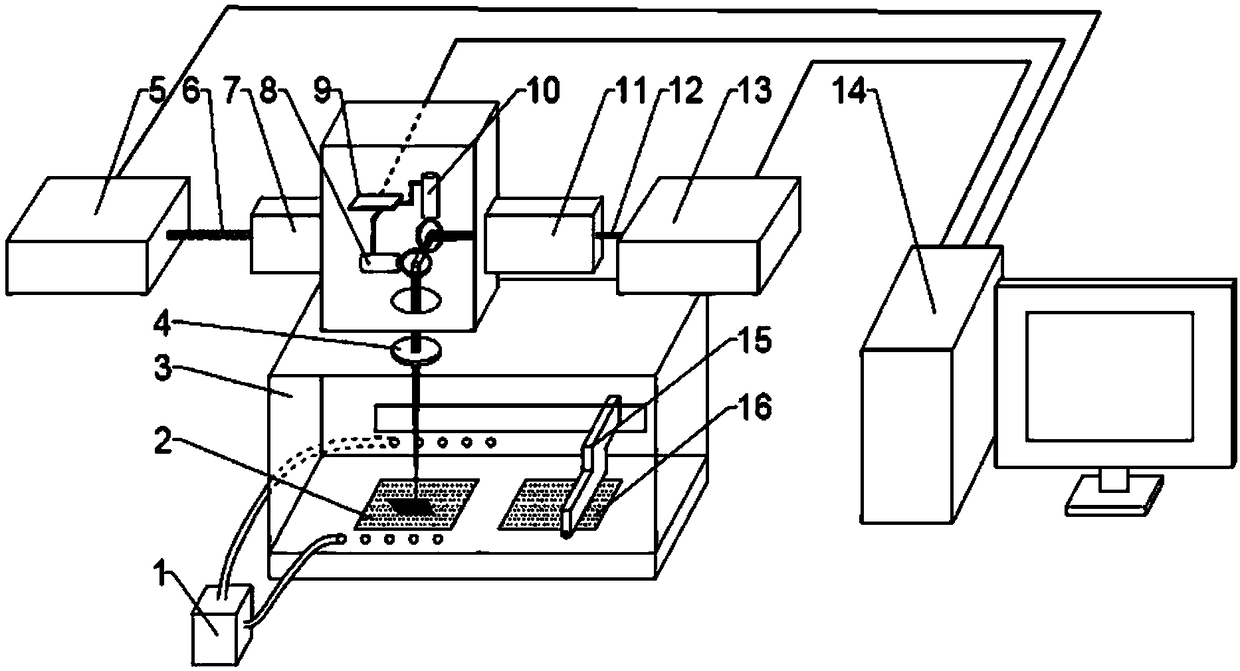

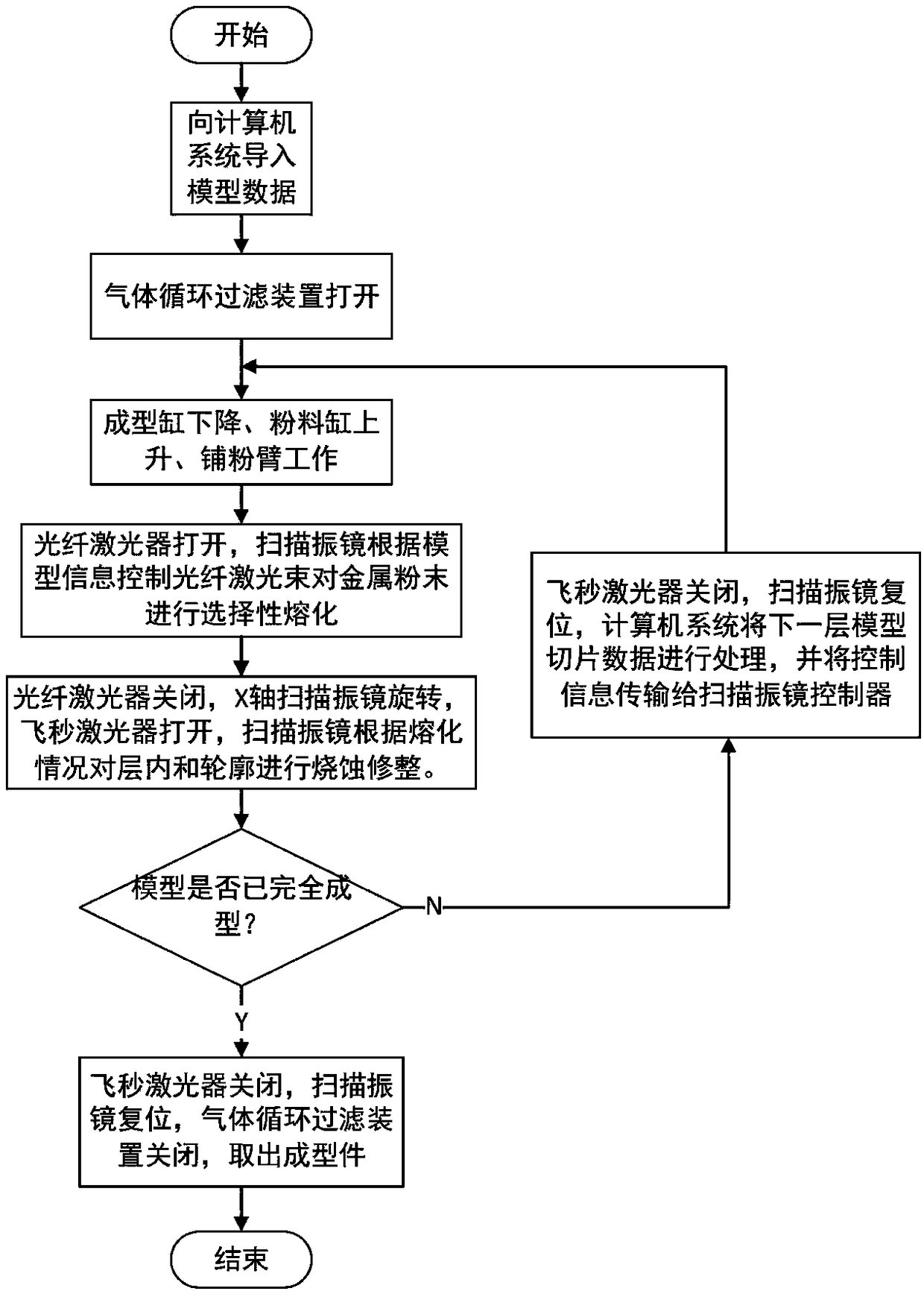

[0037] Such as Figure 1-3 shown. The invention discloses a device for improving the surface quality of SLM molded parts by integrating dual-type lasers, including a computer system 14, a femtosecond laser 5, a fiber laser 13, a femtosecond laser beam expander and collimator 7, and a fiber laser beam expander and collimator 11. Y-axis scanning vibrating mirror 8, X-axis scanning vibrating mirror 10, X-Y scanning vibrating mirror controller 9, lens 4; said femtosecond laser 5 and fiber laser 13 are connected to computer system 14 by telecommunication respectively; X-axis scanning vibrating mirror 10 and the Y-axis scanning vibrating mirror 8 are respectively connected to the computer system 14 through the X-Y scanning vibrating mirror controller 9; the lens 4 is an f-θ lens.

[0038] The X-Y scanning vibrating mirror controller 9 controls the rotation of the X-axis scanning vibrating mirror 10 and the Y-axis scanning vibrating mirror 8;

[0039] The optical path connection se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com