All-fiber pulsed laser

A pulsed laser and all-fiber technology, which is applied in the field of laser technology and nonlinear optics, can solve the problems of cumbersome adjustment steps, large insertion loss, and difficult manufacturing process, and achieve reduced manufacturing cost and process difficulty, high pulse energy, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

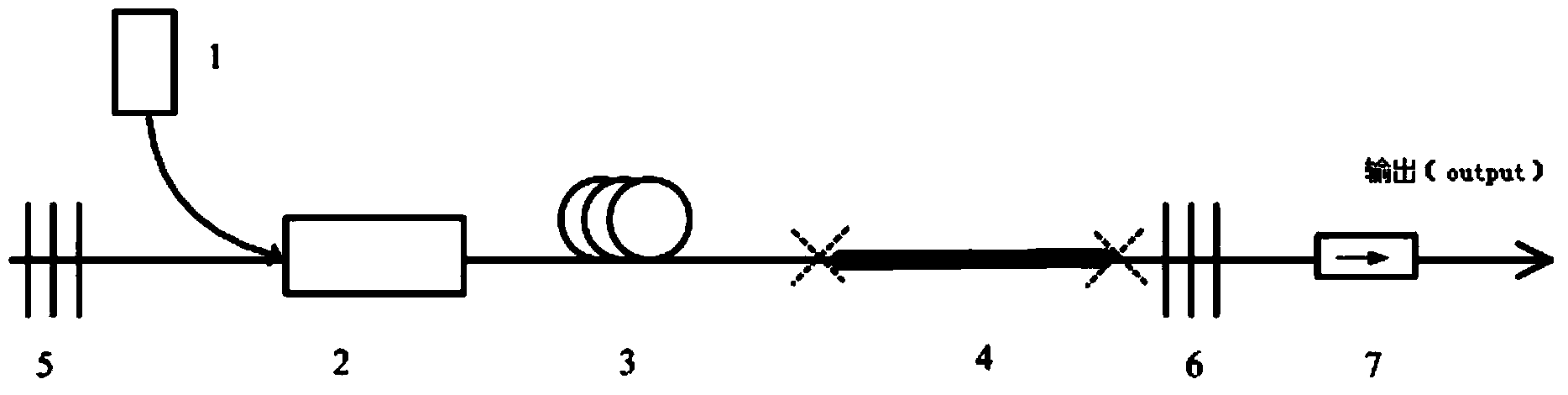

[0025] An all-fiber pulsed laser structure such as figure 1 shown. 1 in the figure is the pump source, which can be a semiconductor laser diode with a center wavelength of 976nm; 2 is a fiber beam combiner, and a (2+1)×1 pump signal beam combiner can be used, such as 6 / 125 or 20 / Type 125; 3 and 4 are rare-earth-doped optical fibers, and high-performance ytterbium-doped optical fibers produced by Nufern Company in the United States can be selected; 5 and 6 are reflective fiber Bragg gratings, which can be either full-reflection or partial reflection gratings, and the reflectivity is R. Among them, 0<R<1; 7 is an optical isolator, an optional polarization-independent optical isolator.

[0026] The pumping light enters the first gain fiber 3 through the pump end of the fiber combiner 2, then reaches the second gain fiber 4 that can absorb saturably, and then reaches the second reflective fiber Bragg grating 6, whose reflectivity is R (0<R<1), the light at the central wavelengt...

Embodiment 2

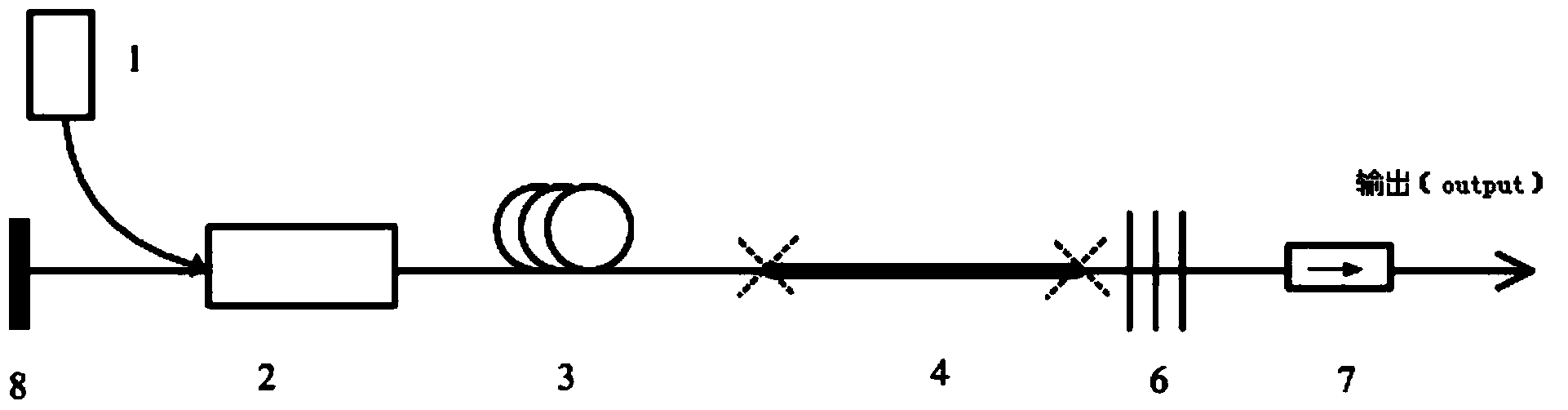

[0028] An all-fiber pulsed laser structure such as figure 2 shown. The only difference from Embodiment 1 is that the reflective fiber Bragg grating 5 is replaced by a total reflection mirror 8 . It is also possible to replace the second reflective fiber Bragg grating 6 with a total reflection mirror.

Embodiment 3

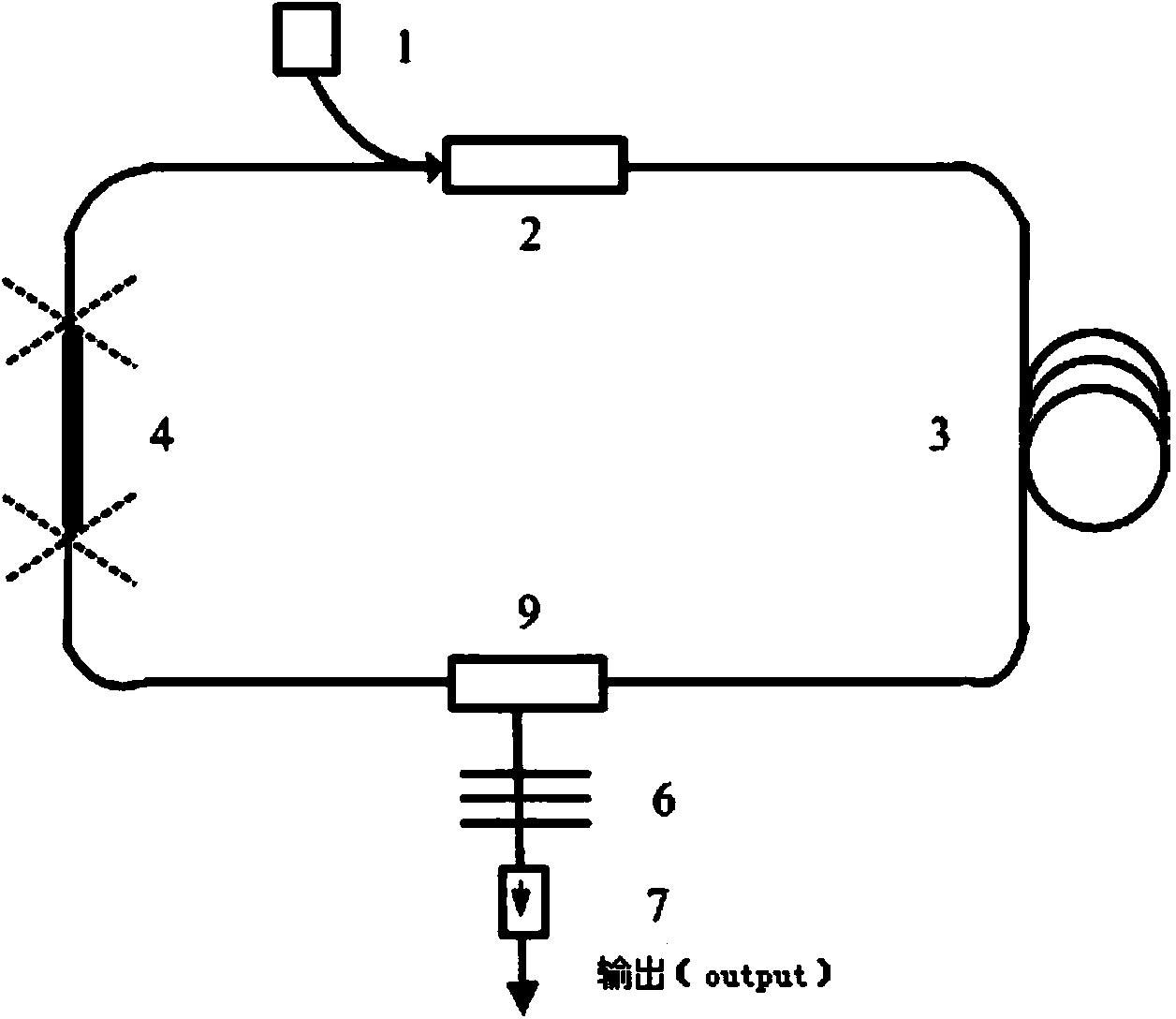

[0030] An all-fiber pulsed laser structure such as image 3 shown. 1 in the figure is the pump source, which can be a semiconductor laser diode with a center wavelength of 976nm; 2 is a fiber beam combiner, which can be a (2+1)×1 pump signal combiner, such as 6 / 125 or 20 / Type 125; 3 and 4 are rare-earth-doped optical fibers, and high-performance ytterbium-doped optical fibers produced by Nufern Company in the United States can be selected; 6 is a reflective fiber Bragg grating, which can be selected from full-reflective or partially reflective gratings, and its reflectivity is R (0 <R<1); 7 is an optical isolator, an optional polarization-independent optical isolator.

[0031] The pumping light enters through the pump end of the fiber combiner 2, passes through the first gain fiber 3, and enters from the incident end of the circulator 9. The working direction of the circulator is the incident end→common end→exit end, the direction is irreversible, and the common The end is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com