Collapsible lattice beam, truss and construction including such a beam

A technology of truss beams and structures, which is applied to truss structures, elongated structural members for load-bearing, truss beams, etc., and can solve the problems of large volume of pre-assembled parts, space loss, and increased installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

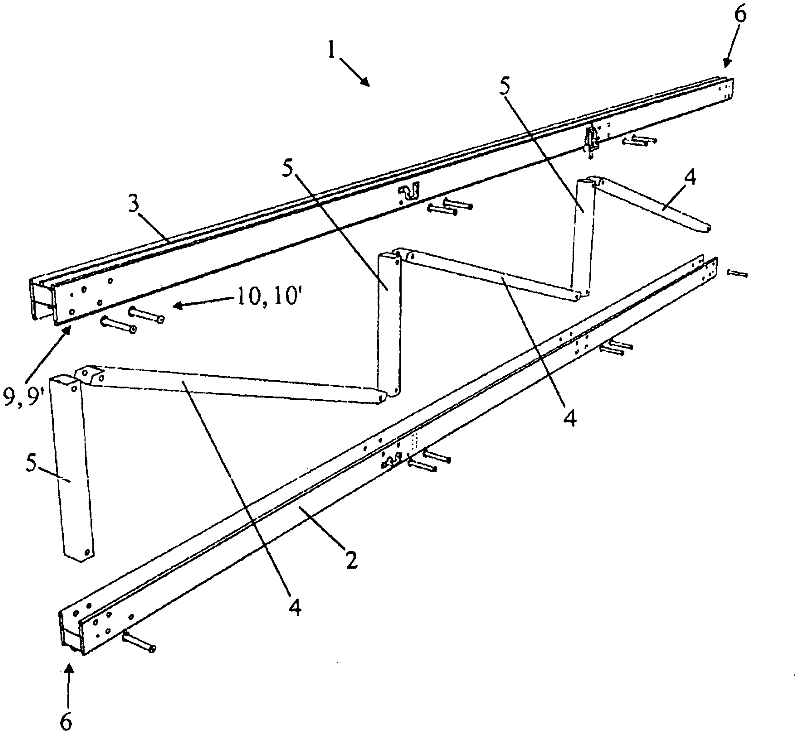

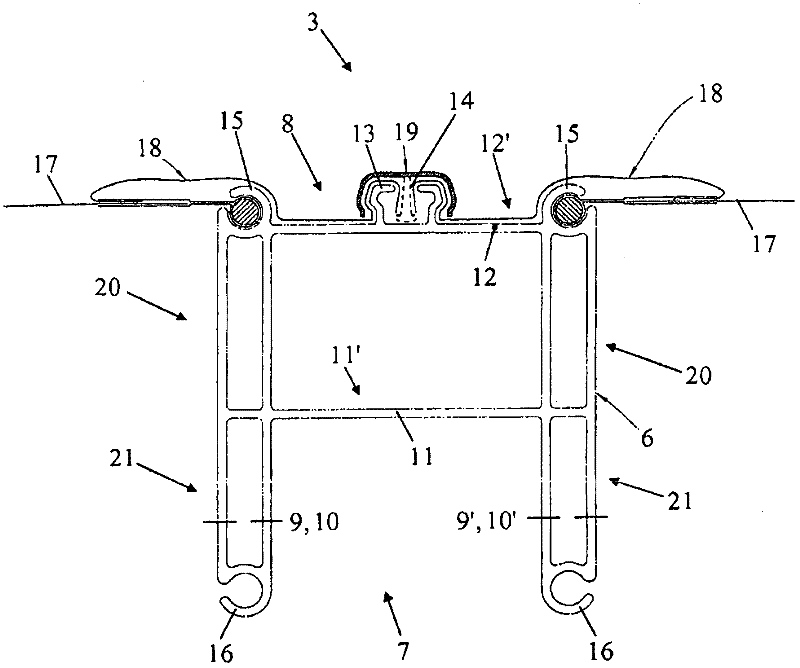

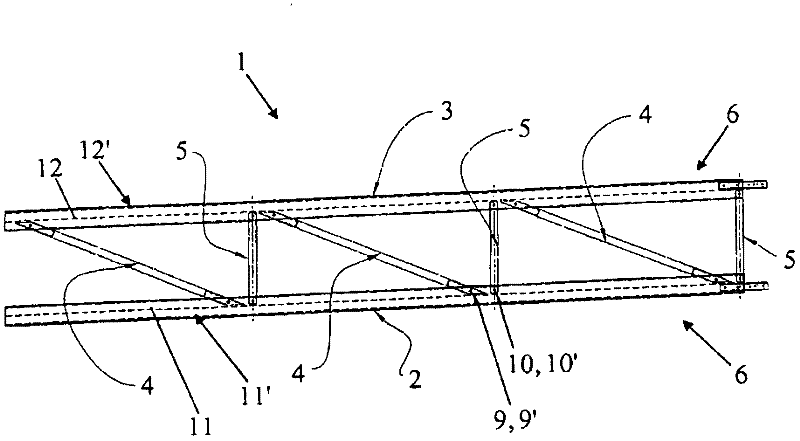

[0015] According to the present invention and as shown in the accompanying drawings figure 1 Particularly shown, the pre-assembled truss girder 1 for constructing the roof truss of a building, especially a tent class or a tension cloth structure, is characterized in that the pre-assembled truss girder mainly includes a lower beam 2 and an upper beam 3, The lower beam 2 and the upper beam 3 are connected between them by at least one diagonal bar 4 fixed to said lower beam 2 and upper beam 3 in a pivotable manner between a transport position and an installation position , in the transport position, the lower beam 2 and the upper beam 3 are close to each other, preferably in direct contact with each other, and in the installation position, the lower beam 2 and the upper beam 3 are far away from each other, preferably in the at least one inclined The bar 4 and one of the two beams 2, 3 move away from each other by forming an acute angle between them, preferably an acute angle of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com