Slant-leg rigid-frame-type supporting structure of super-high-rise building mega-frame bottom layer and construction method

A giant frame and support structure technology, applied in the direction of building components, building structures, buildings, etc., can solve the poor matching between the bottom herringbone support and the upper X cross support, the poor aesthetic effect of the building appearance, and affect the use of the ground floor hall, etc. problems, to achieve good application prospects, good seismic performance, and large lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

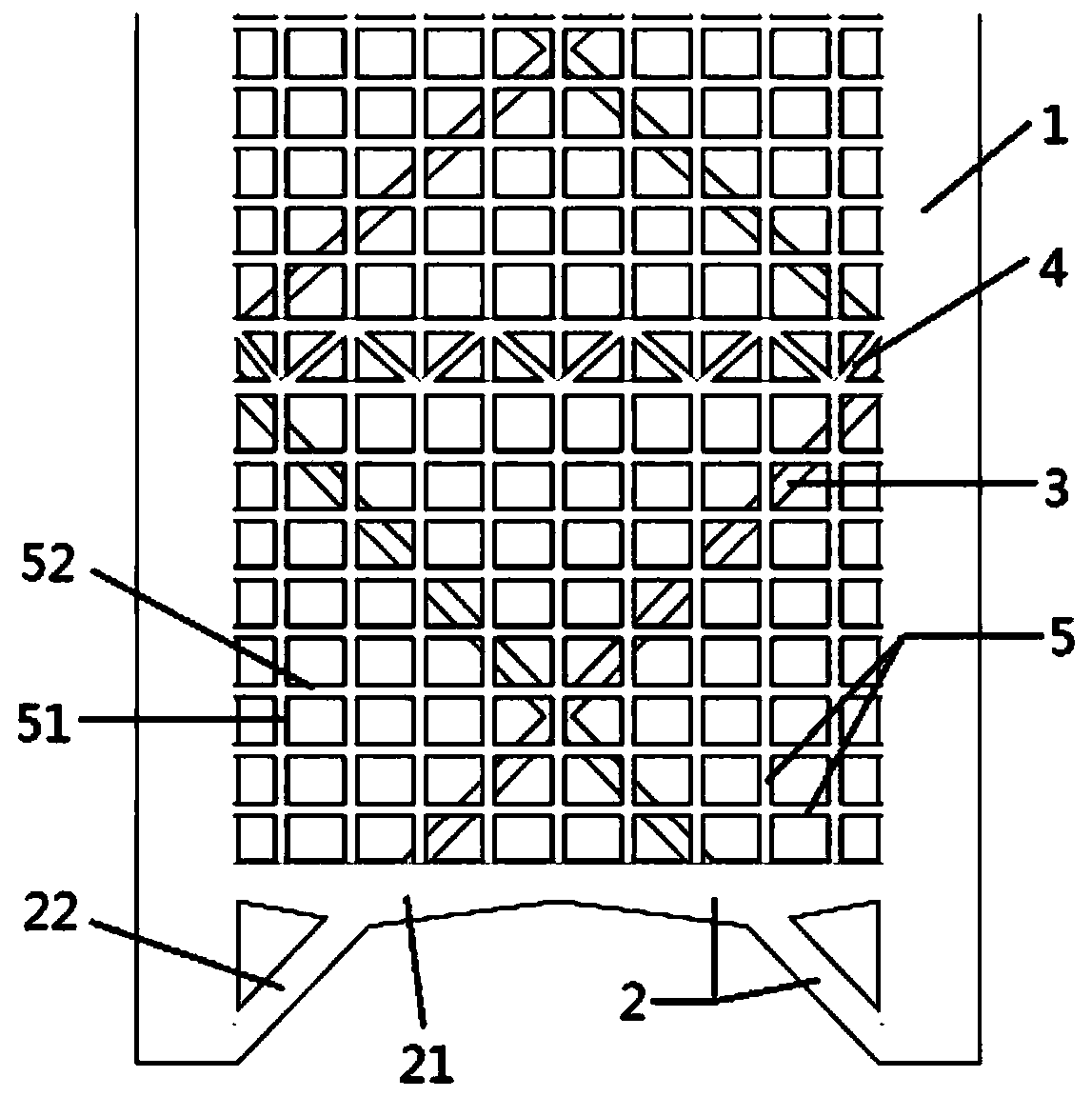

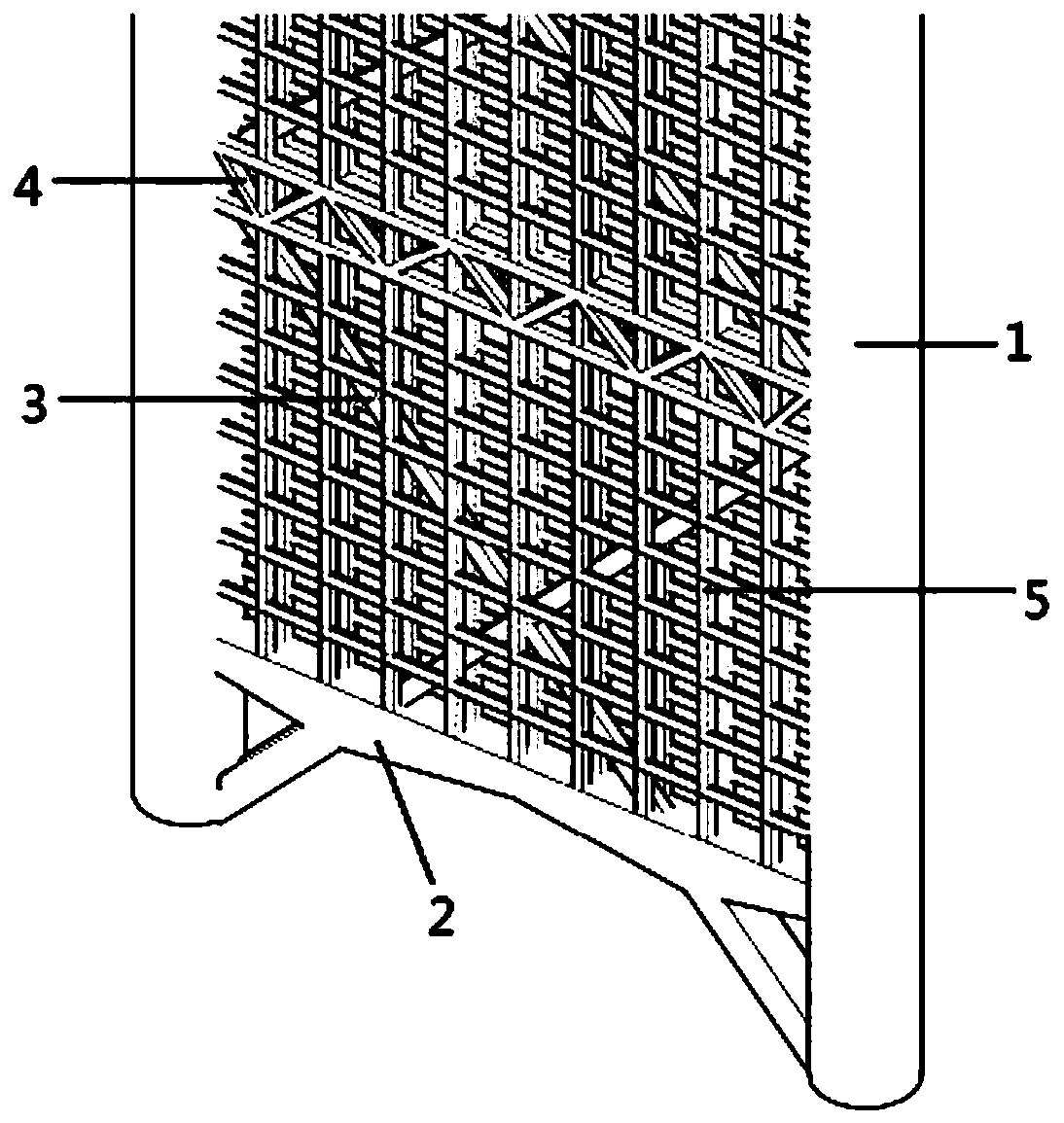

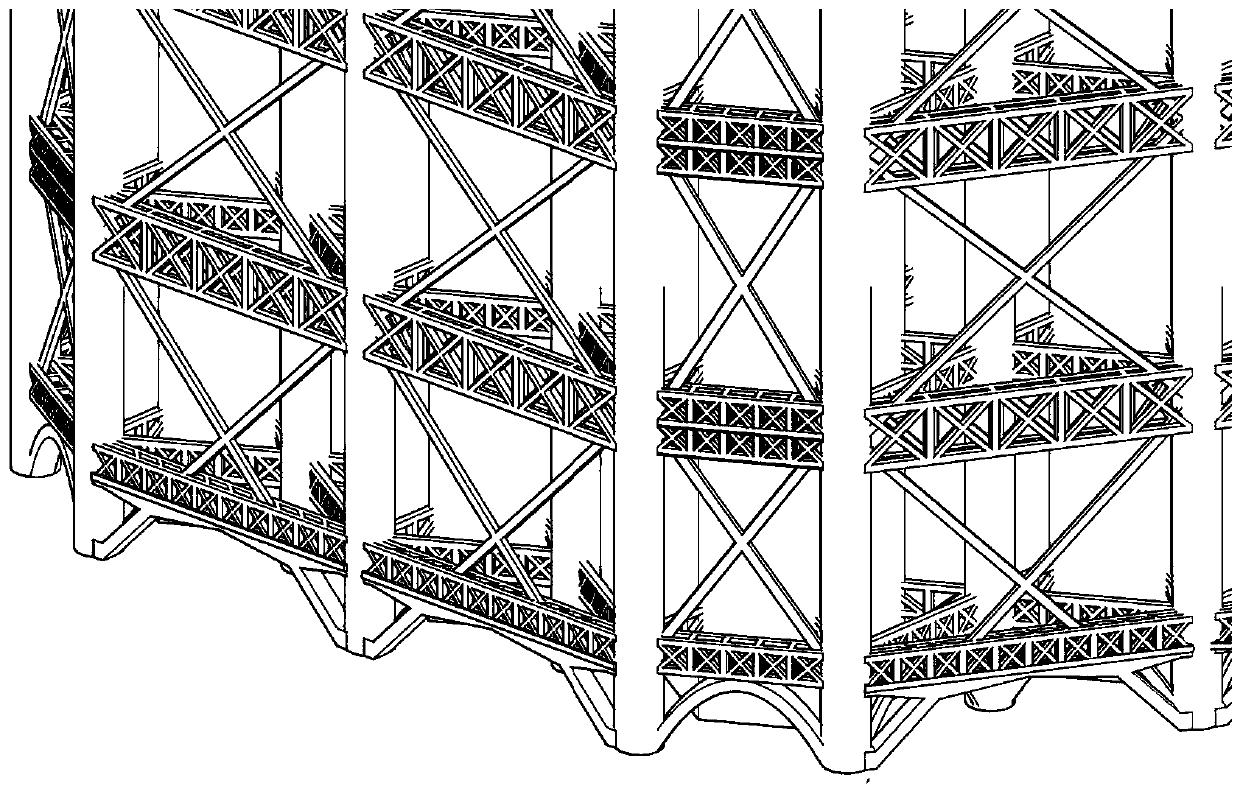

[0042] Example 1: A giant frame-core tube structure system, the building height is 700 meters, the interior is a grid tube type double steel plate concrete composite shear wall core tube, the bottom shear wall core tube is 2.0 meters thick, and the outside is a giant frame structural system. The diameter of the circular steel pipe giant column at the bottom is 6 meters, and the storey height is 5 meters.

[0043] The shape of the external giant frame structure system is hexagonal, and the distance between the opposite sides of the hexagonal giant frame system is 100 meters. There are six circular giant frame columns 1 in the whole building. The diameter of the bottom of the circular steel pipe giant frame column 1 is 6 meters, the height of the building is 5 meters, one refuge reinforcement layer is set at 50 meters, and the span of the ring belt truss is 50 meters.

[0044] The ground floor of the building is a three-storey hollow hall. The entrance of the hollow hall adopts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com