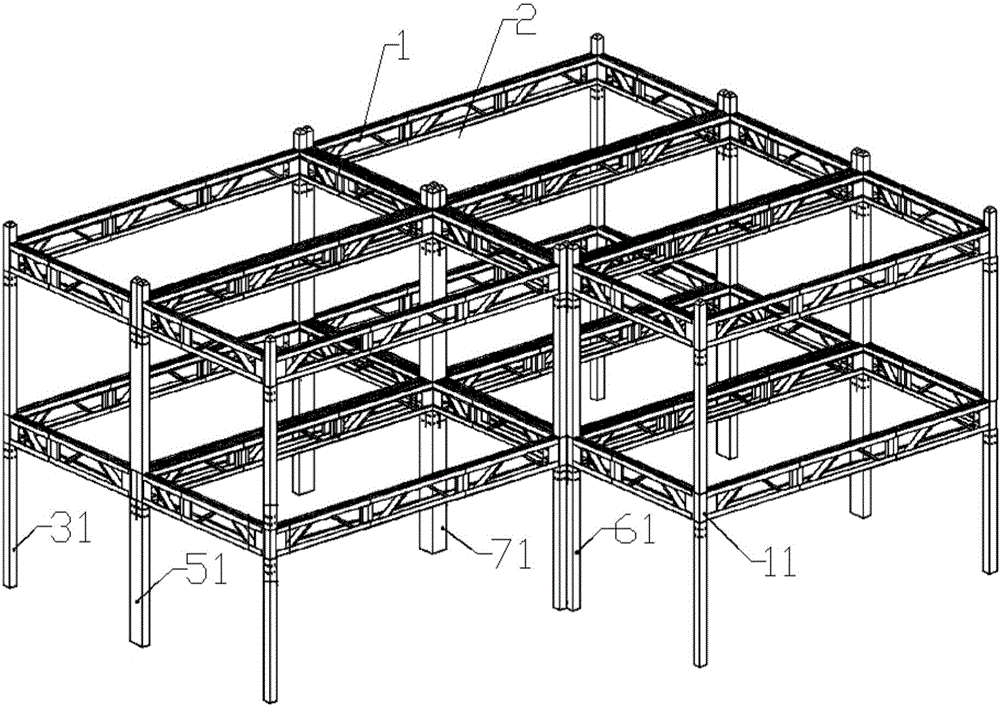

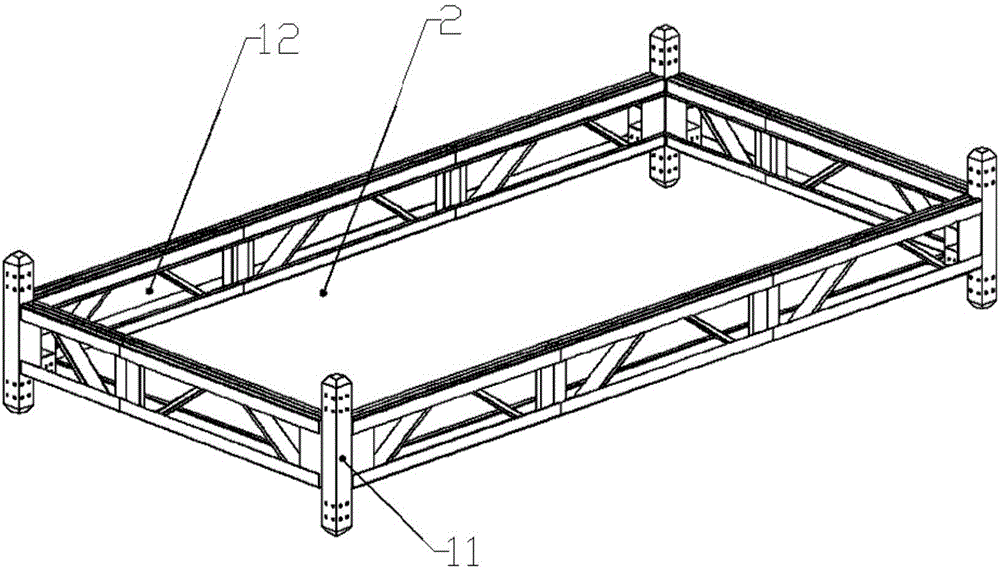

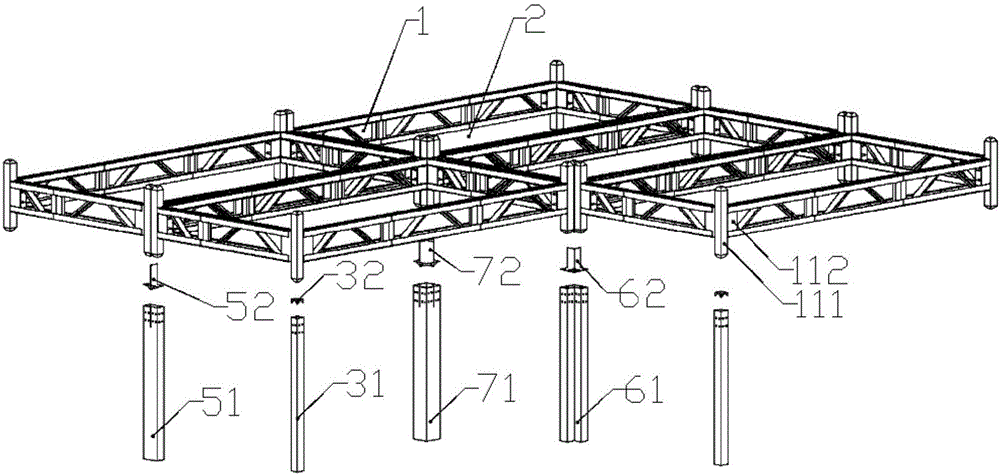

Assembled light steel frame mortise-tenon inserted-connected structure and mounting method

A plug-in structure and prefabricated technology, which is applied to truss structures, building structures, joists, etc., can solve the problems of complex installation process and large assembly workload of prefabricated buildings, so as to ensure construction quality, reduce construction period, Enhance the effect of force rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. However, the uses and purposes of these exemplary embodiments are only used to illustrate the present invention, and do not constitute any form of limitation to the actual protection scope of the present invention, nor limit the protection scope of the present invention thereto.

[0040] Some orientation words are defined in the present invention. Unless otherwise specified, the orientation words used such as "upper and lower" refer to the normal use of the prefabricated light steel frame mortise and tenon joint structure provided by the present invention. defined below, and with the attached figure 1 The up, down, left, and right directions shown in are the same. "Inside and outside" refer to inside and outside relative to the outline of each part itself. These orientation words are adopted for easy understanding, and thus do not constitute a limitatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com