Water injection, cooling and denoising system for rocket launching

A technology of water spray cooling and noise reduction system, which is applied to rocket launchers, offensive equipment, weapon types, etc., can solve the problems of prolonged gas flow ablation, weakened gas flow discharge ability, increased area, etc., and achieves change in noise. Propagation path, effect of reducing temperature and noise intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

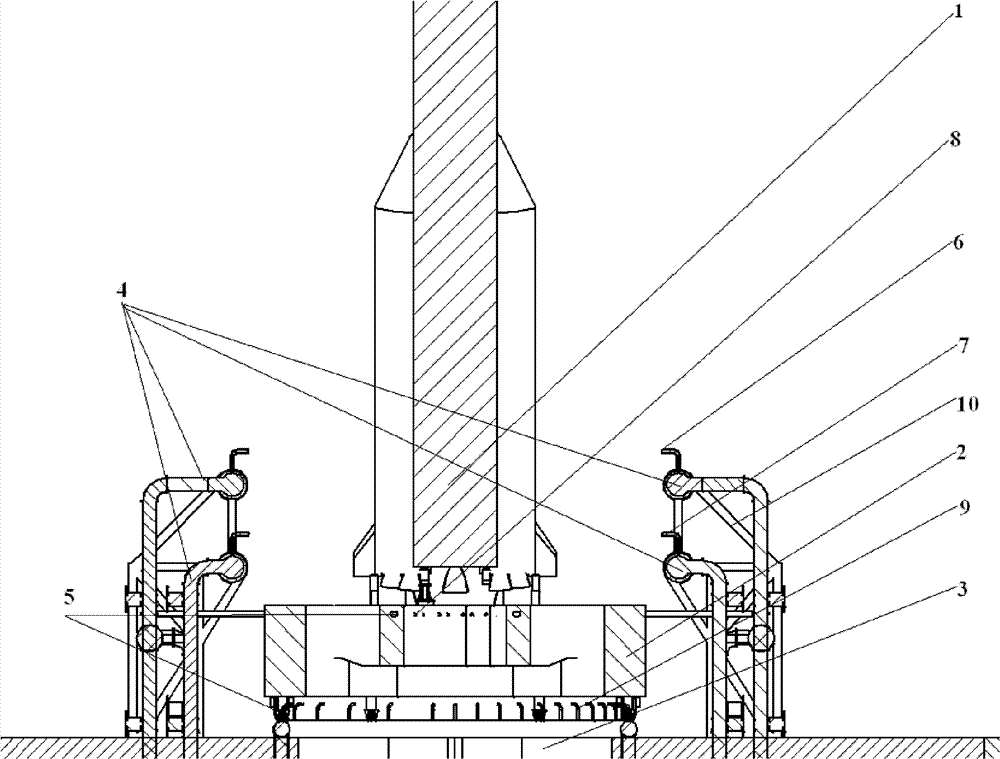

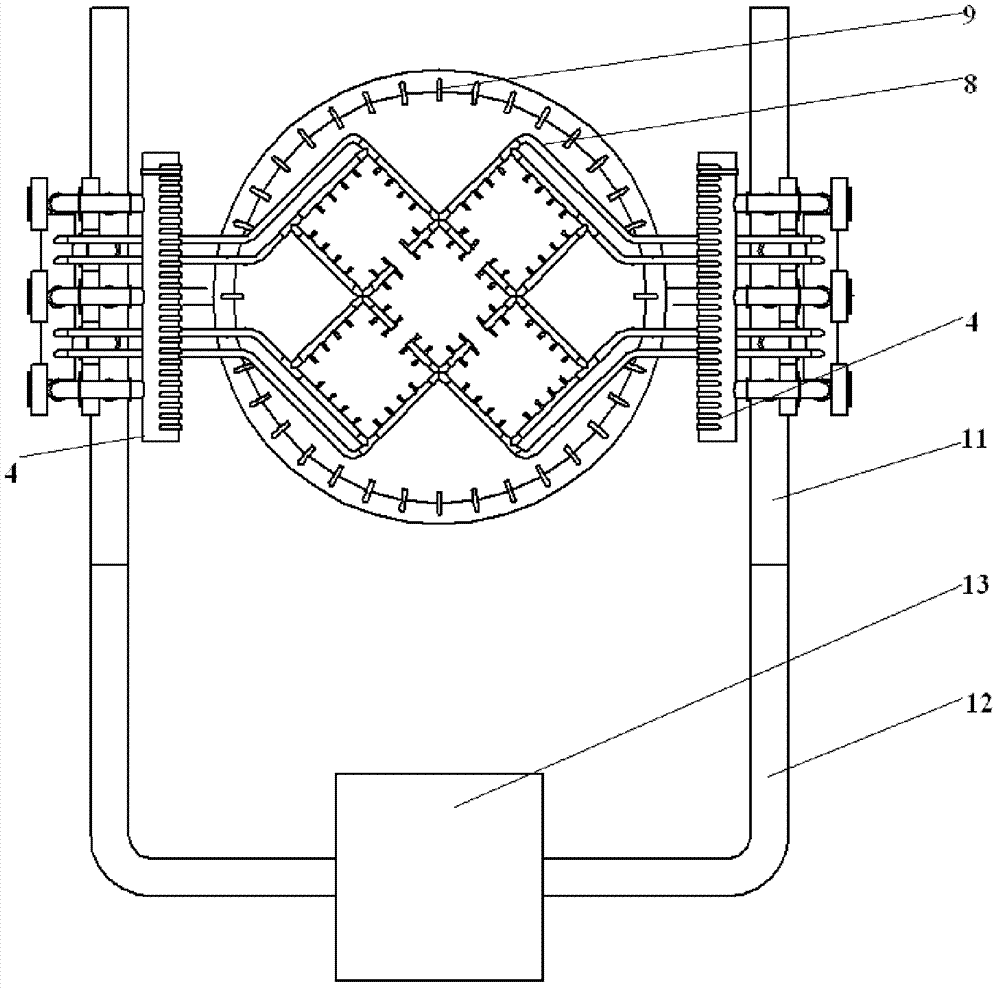

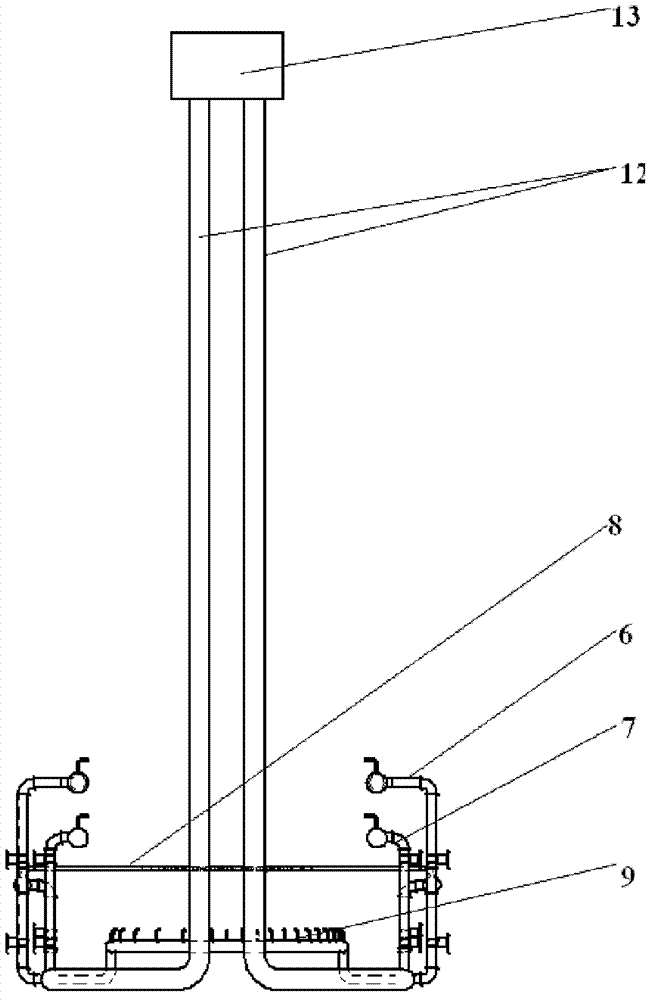

[0033] Such as figure 1 , figure 2 and image 3As shown, the rocket launch water spray cooling and noise reduction system of the present invention includes an outer water spray device 4, an inner water spray device 5, a support truss 10, a lower water reservoir 11, a water spray main pipe 12 and a high water tank 13 The launch site is provided with a high-level water tank 13, and two water spraying main guide pipes 12 are drawn from the high-level water tank 13 to both sides of the launch platform walking part, and near the launch platform diversion groove, to provide water flow and water pressure conditions during work; The main water spraying pipes 12 are all connected to the lower water reservoir 11, and the lower water reservoir 11 is used to keep the liquid in it at an equal pressure; Water device 5, wherein outer layer water spray d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com