Step-by-step hoisting construction method of mega-frame steel truss beam

A giant frame and steel truss girder technology, which is applied in the hoisting method of giant frame steel truss girders on high-rise buildings, can solve the problem that the lifting capacity of tower cranes cannot be fully utilized, masts/pulling rods cannot be safely operated, and high-altitude hoisting cannot be performed, etc. problems, to achieve the effect of reducing investment in machinery and equipment, shortening the construction period, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to further describe the technical solution of this patent, so that this technical field can be implemented according to what we have described, let us illustrate with examples below:

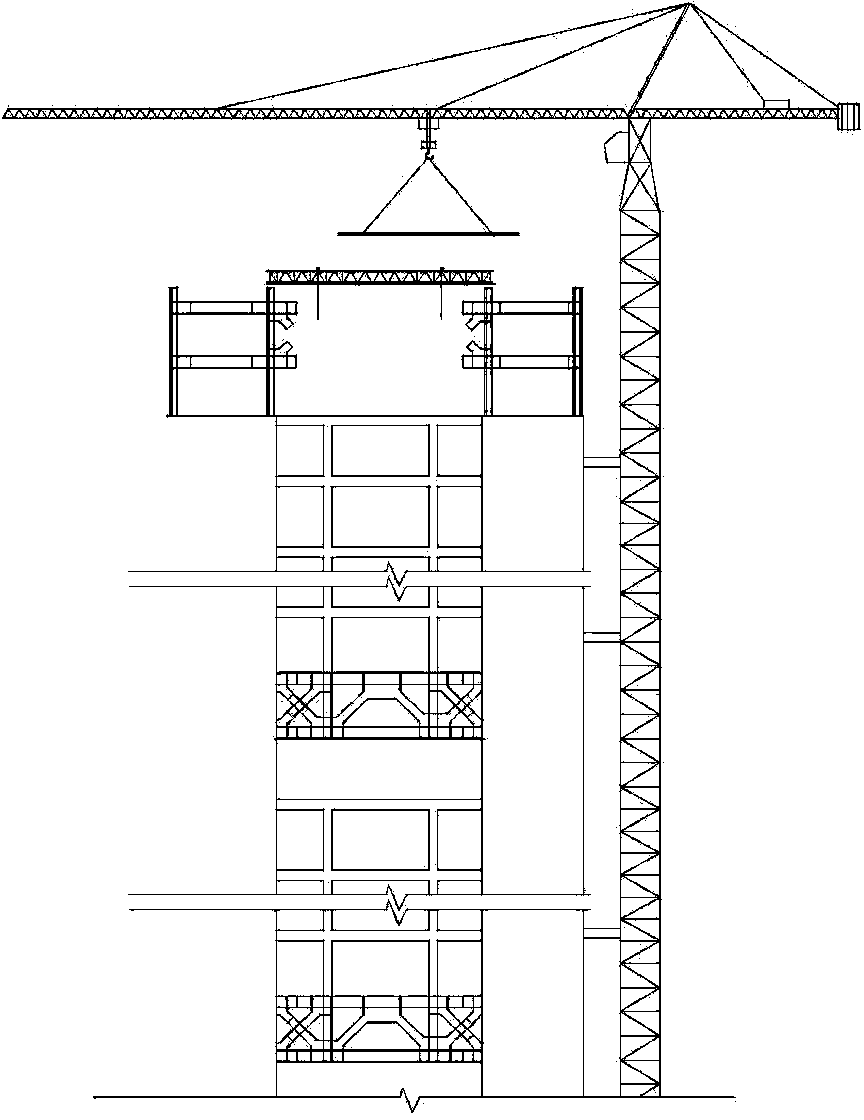

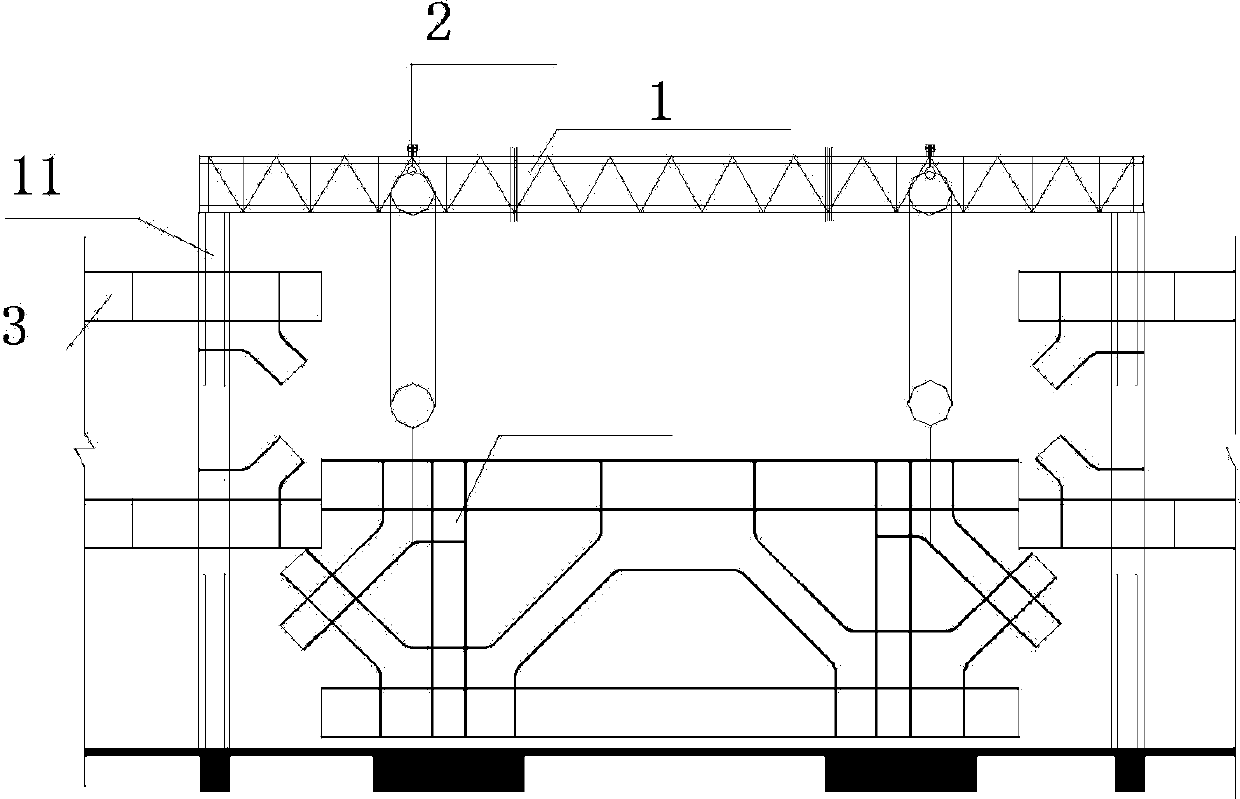

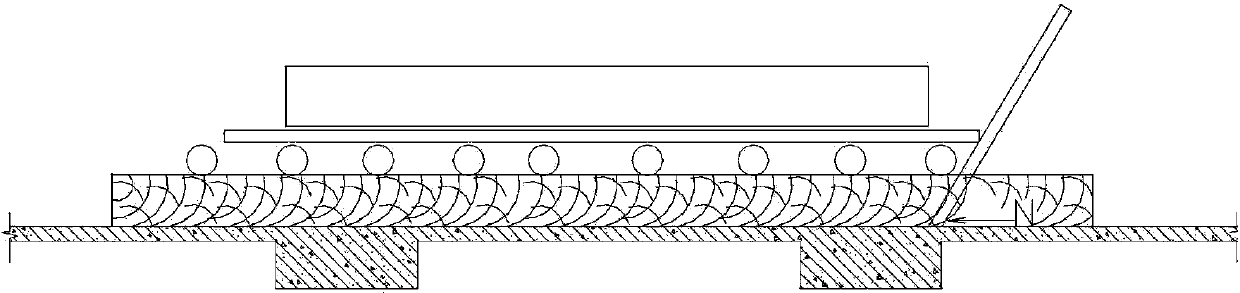

[0073] The steel trusses were hoisted in place through step-by-step hoisting using tower cranes, roller bars, and gantry cranes successively. First use the tower crane as the main vertical transportation machine, make full use of the maximum lifting capacity of the tower crane, lift the steel truss from the ground, lift it to the floor of the first floor below the transfer floor, and place it close to the tower body; then Through the translation device on the floor, the steel truss is shifted to the bottom of the gantry, and finally the steel truss is hoisted from the floor with a gantry crane, lifted to the installation level, and finally fixed in place.

[0074] The gantry is composed of installed structural steel columns and specially fabricated tool-type steel beams ( Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com