Assembled low-energy consumption integrated wall

A low-energy, prefabricated technology, applied in the field of building materials, can solve problems such as thermal insulation, heat insulation, sound insulation, and moisture-proof performance are not outstanding, masonry wall construction is labor-intensive, and cement slurry is not allowed to be prepared. Excellent performance, superior cross-section performance, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

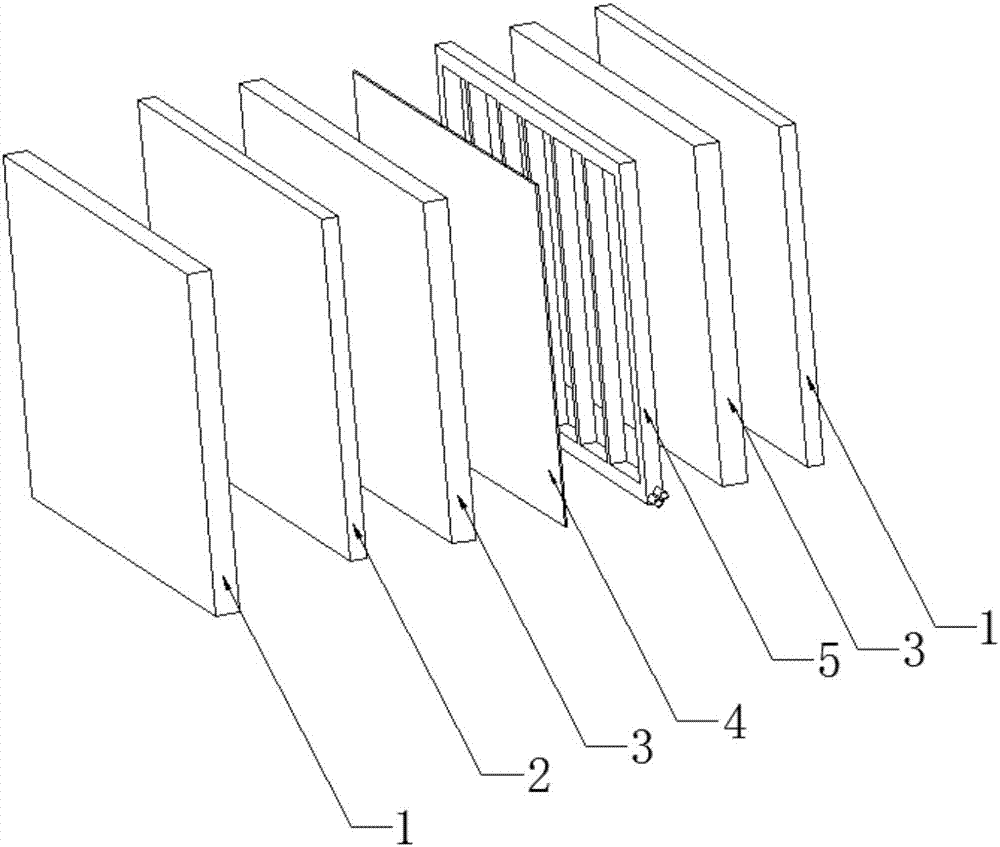

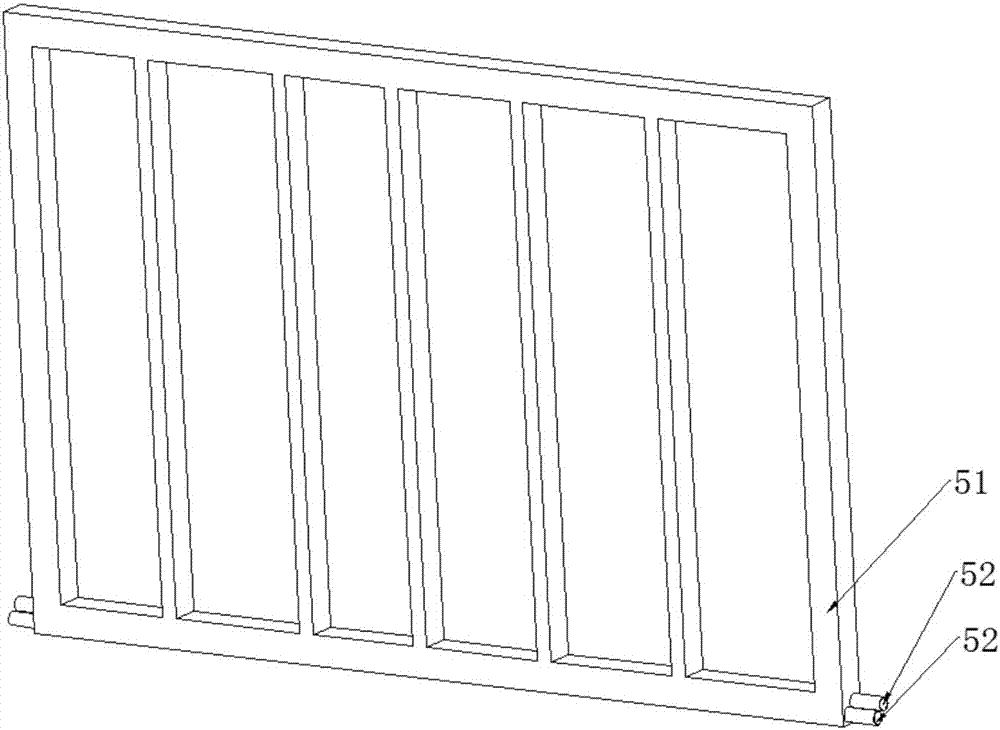

[0029] see figure 1 , in this embodiment, a prefabricated low energy consumption integrated wall of the present invention includes a mortar board 1, a structural board 3, a sound insulation board 5, a moisture-proof film 4, an airgel board 2 and an interior decoration board 6, and the mortar board 1 Including reinforcement mesh 11 and pouring mortar, wherein the reinforcement mesh 11 can be made by bundling multi-layer staggered peak-stacked wavy steel bars, and the wavy-shaped steel bars are arranged in parallel, cross-arranged and staggered-peak stacked to form a sparse structure with a certain thickness. Cuboid shape, when wavy steel mesh 11 is bound in the present embodiment, the crest of a wavy steel bar along the thickness direction corresponds to the trough of another wavy crest, and the crest is tangent to the trough and bound and fixed, and the bound steel mesh 11 is placed In the pouring tank, the mortar can be directly poured into the cuboid formed by the steel mesh...

Embodiment 2

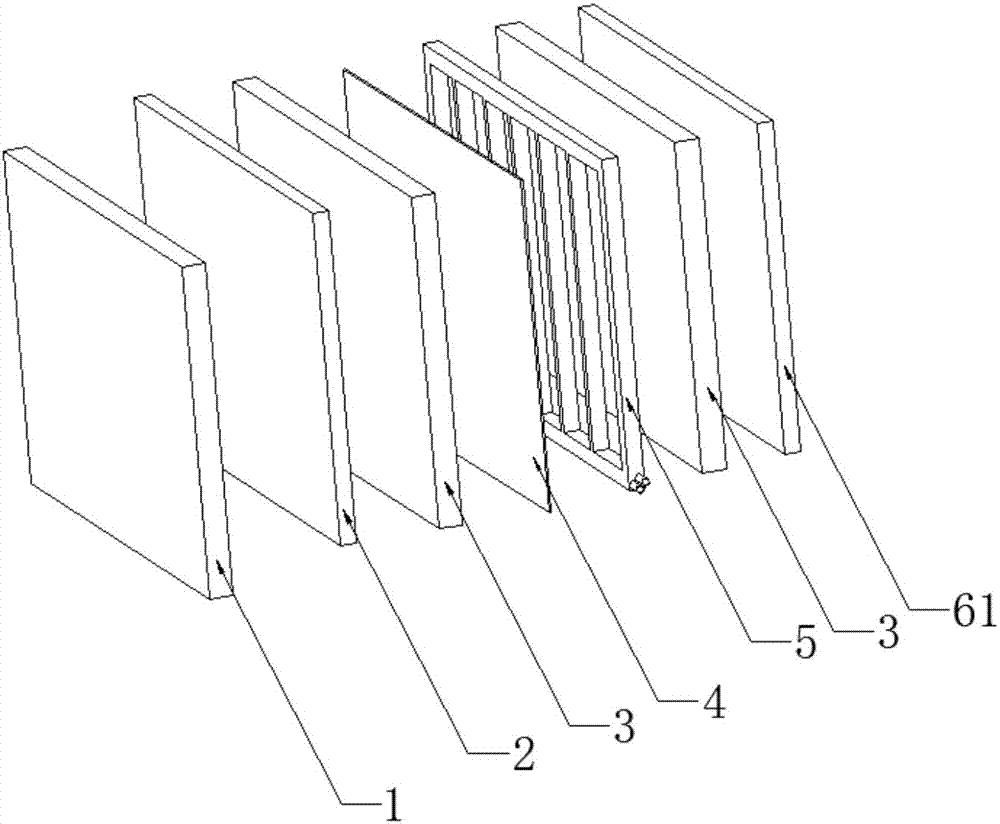

[0034] see Figure 5 , in this embodiment, each functional layer of the wall is gypsum board 61, structural board 3, sound insulation board 5, moisture-proof film 4, structural board 3, airgel board 2, mortar board 1 sequentially from the inner side of the wall body to the outer side, Among them, the wall trim panel 6 is set as gypsum board 61. Gypsum board 61 is a common decoration material with light weight, high strength, thin thickness, convenient processing, sound insulation, heat insulation and fire prevention. Gypsum board 61 As the innermost structure of the wall, the decoration cost can be greatly saved, and the user can move in as soon as possible; and the steel mesh 11 in the mortar board 1 in this embodiment is a single-layer steel mesh 11 formed by straight steel bars arranged in parallel and vertically intersected. A column is set at the intersection of the single-layer steel mesh 11 to connect two layers of the same single-layer steel mesh 11 to form a three-dim...

Embodiment 3

[0036] see Image 6 , in order to further save costs and optimize the process flow, in this embodiment, the mortar board is poured with a combination of trapezoidal steel mesh 11 and flat mesh 12. When pouring, the mortar is more likely to fill the gaps in the steel mesh and shorten the process cycle of the mortar board. Other than that, other structures of this embodiment are the same as those of Embodiment 1.

[0037] The advantages of the present invention are:

[0038] 1. The assembled low-energy-consumption integrated wall body provided by the present invention is convenient and quick to assemble, and is composed of several functional layers. Each layer of wall panels has at least one outstanding performance. These walls composed of several layers of wall panels The comprehensive performance of the body is more superior, and the user experience is more comfortable. It greatly reduces the difficulty of construction, shortens the construction period, not only meets the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature tolerance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com