Energy-saving dry and wet dual-use composite building mortar

A dry and wet dual-purpose, energy-saving technology, applied in the field of building materials, can solve the problems of multi-porosity, difficult to control water evaporation, and difficult to accurately control the quality of slurry, etc., to achieve strong durability, good bonding effect, and improve hardening quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation methods of Examples 1 to 8 are as follows: Step 1, various solid raw materials are classified and stacked, and after drying and screening, each raw material is weighed according to the mass ratio;

[0025] Step 2, adding sand and electric slag to the cement and stirring evenly, then adding crushed material and dry powdered lime, and continuously stirring to obtain a uniformly dispersed mixed material;

[0026] Step 3: add sludge, silt and dry powder latex to the mixed material in sequence and continue to stir until uniformly dispersed, then put into a pulverizer and pulverize into fine particles or powder, and mix well to obtain a composite building mortar.

[0027] Examples 1 to 4 use wet methods: add composite construction mortar to water, stir evenly to obtain slurry, and then evenly coat the slurry on the wall.

[0028] Examples 5 to 8 use the dry method: evenly sprinkle the composite construction slurry on the wet painted surface, floor or construct...

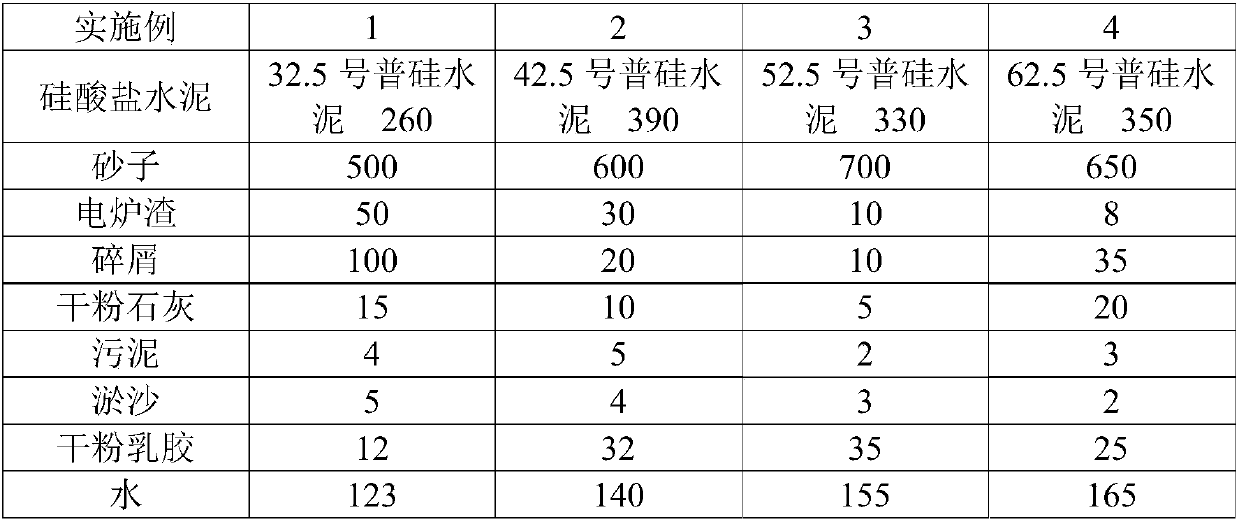

Embodiment 1- Embodiment 4

[0031]

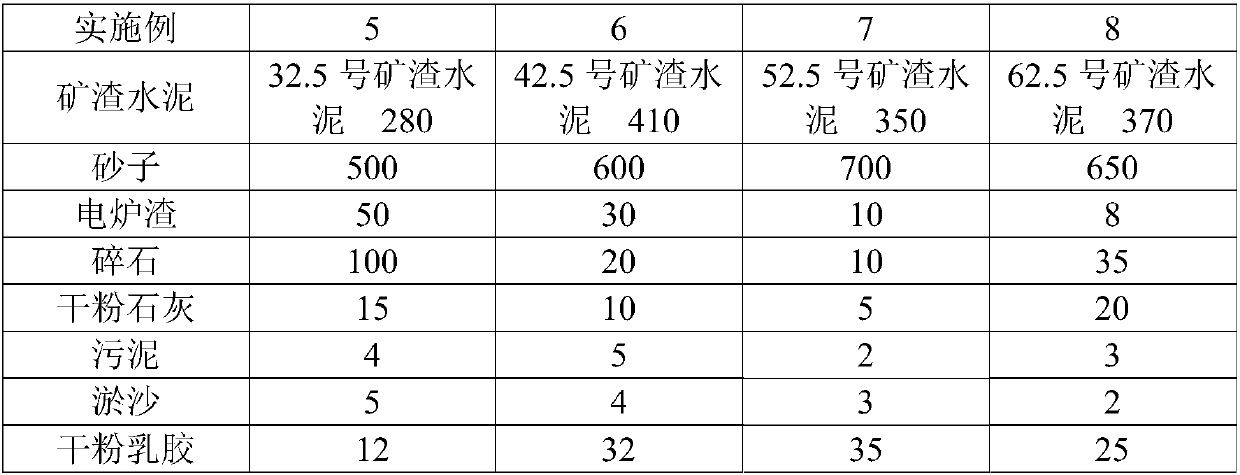

Embodiment 5- Embodiment 8

[0033]

[0034] Example 1-Example 4, the slurry was obtained according to the above mass ratio and preparation method, and then the slurry was evenly coated on the construction surface. The construction is carried out according to the requirements, and the setting time, strength time and maintenance period are 28 days, which can meet the project quality requirements.

[0035] After the mortar is mixed with water, its service time requirements are as follows: the ambient temperature is 0°C-10°C, it should be used up within 5 hours; the ambient temperature is 10°C-20°C, it should be used up within 3 hours, and the ambient temperature is 20°C-20°C. 30°C, it should be used within 2 hours; the ambient temperature is 30°C-37°C, it should be used within 1 hour; the mortar should be properly stirred to increase its mobility.

[0036] According to the ordinary Portland cement used, the strength of Example 1-Example 4 can be divided into four grades: Ⅰ (M5.0 strength), Ⅱ (M7.5 streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com