Method for lifting base plane of power transmission line tower by adopting steel pipe connecting leg

A technology of transmission lines and steel pipes, which is applied in infrastructure engineering, construction, etc., can solve the problems of large amount of steel and concrete used, strict construction quality requirements, and long concrete curing time, and achieve high bearing capacity, shorten construction period, and shape coefficient small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

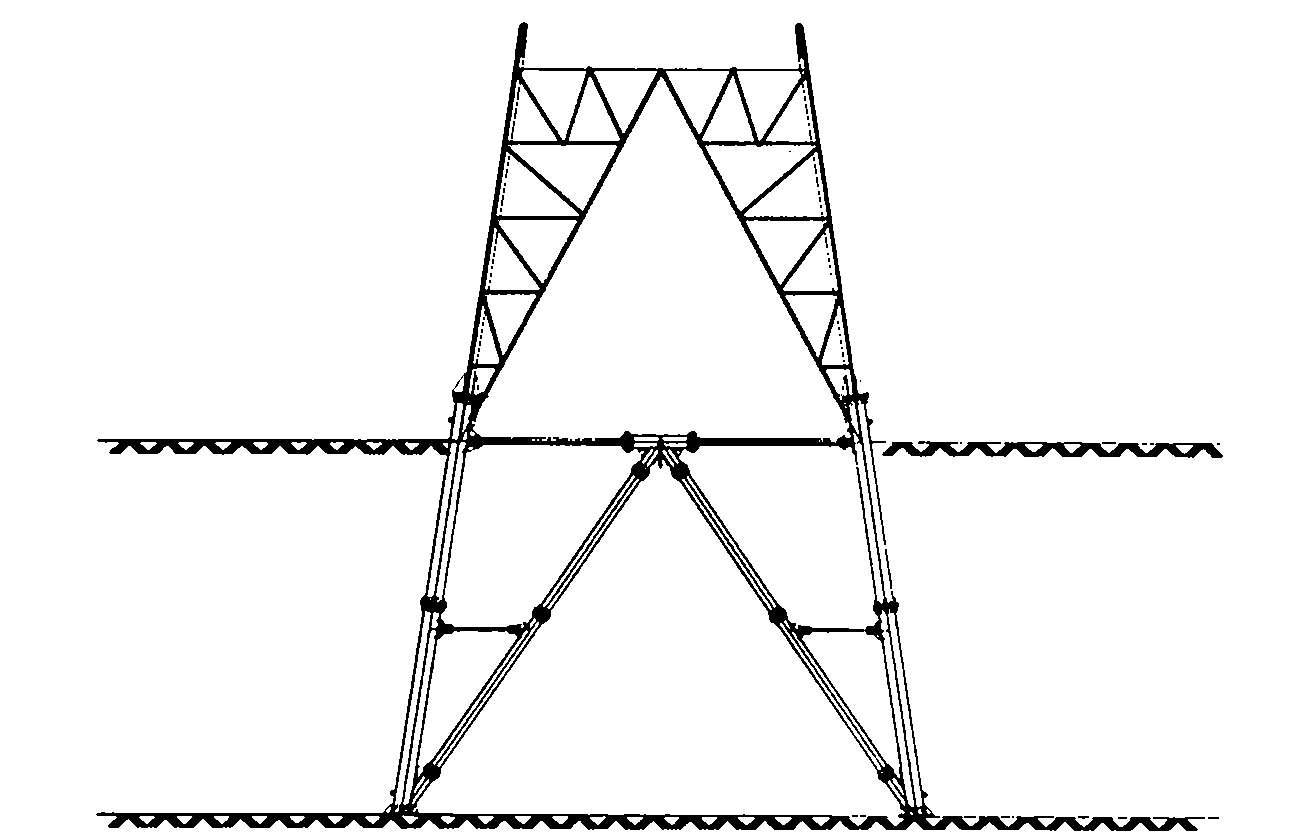

[0014] figure 1 It is a schematic diagram of the lifting of the angle steel tower of the present invention, and its concrete steps are as follows:

[0015] First lift the angle steel tower from the foot of the angle steel tower; then connect the main material of the steel pipe with the main material of the angle steel tower with a flange; The present invention is to add steel pipe connecting legs at the foot of the angle steel tower, and form a space lattice structure through circular steel pipes, round steel or section steel, etc., and solve the problem of conventional filling time sequence under the condition of satisfying the force of the tower. At the same time, it solves the shortcomings of the conventional foundation raising scheme, such as long filling time, strict construction quality requirements, long concrete curing time, increased body engineering volume, and poor economy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com