Profiled hollow steel plate

A profiled steel plate, hollow technology, applied in thermal insulation, fire protection, floor and other directions, can solve the problems of insufficient strength, sound insulation and heat insulation, and achieve the effect of superior cross-sectional characteristics, reducing constant load, and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

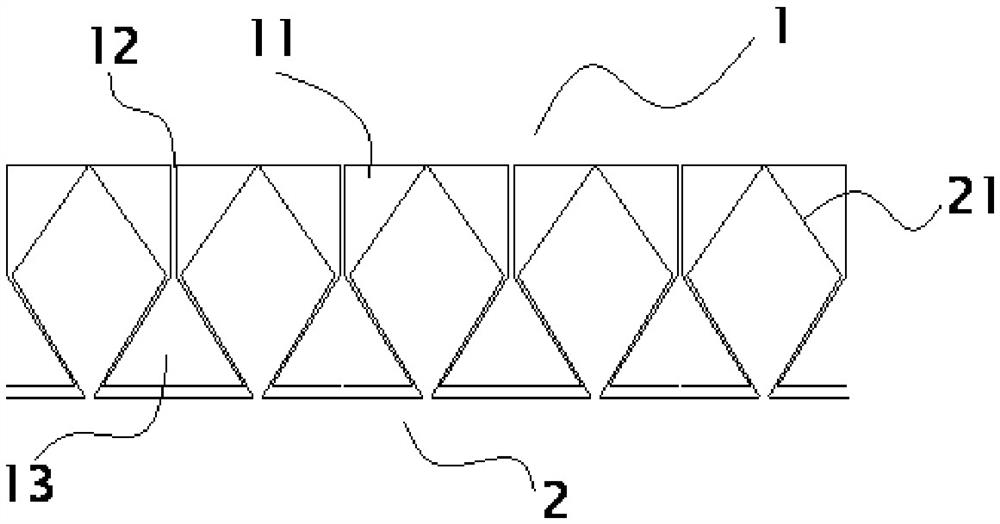

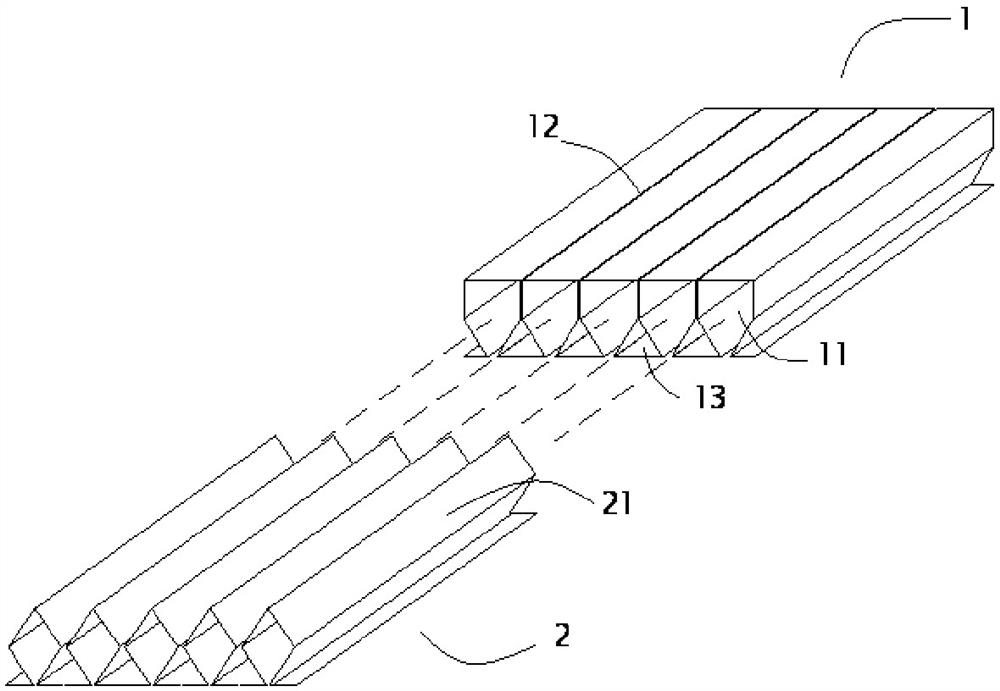

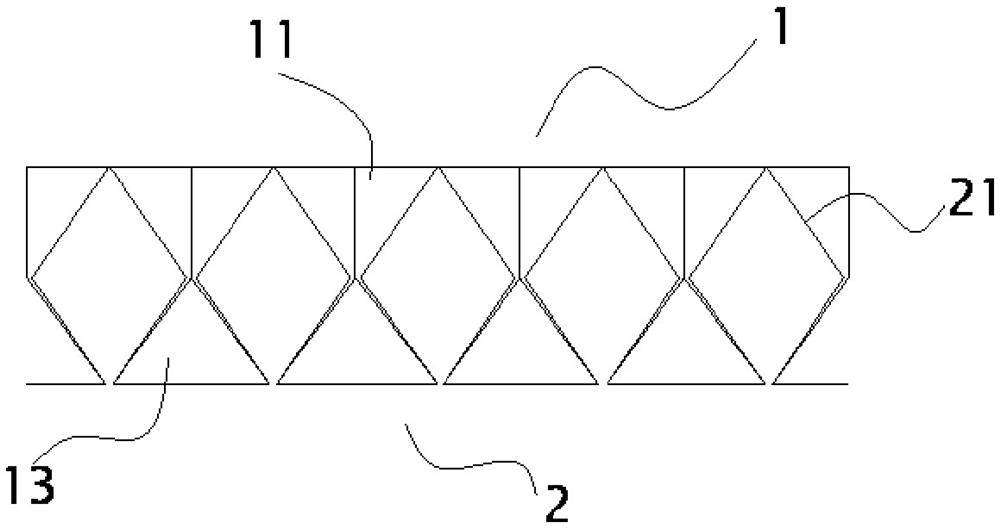

[0071] See Figure 1 to 6 Embodiment 1 shown in the arrangement of the discharge type of the present invention, including two laminated steel sheets, a combination of two-laminated steel sheets, and two-laminated steel sheets nested to each other. Specifically, the latch plate 1 and the buckle plate 2 are included. Each of the latch plates 1 is formed from at least one steel sheet. Each of the buckles 2 is formed from at least one steel plate.

[0072] The latch plate 1 is provided with a plurality of cavities 11 in the horizontal direction 11, the cavity 11, by the locking plate 1, and the lower end level of the top end is inverted. Cross-sectional shape; The cavity first 11 is horizontally symmetrical in the vertical direction axis and forms a symmetrical pressure. A locking plate gap 12 is provided between the outer walls of the cavity 11.

[0073] After the support body 21 and the nested fitting of the cavity 11, the arrangement of the arrangement of the arrangement of the disc...

Embodiment 2

[0084] See Figure 7 to 11 Example 2 of the present invention is shown in the first embodiment of the present invention, the buckle bone plate 2 is two layers nested sequentially.

[0085] The support body 21 includes a stacking of the first support unit 215 and the second support unit 216, the first support unit 215 and the second support unit 216, each continuously reverse bend formed by the buckle plate 2. . Specifically, the bone plate 2 is folded into the first side 201, the second side 202, the third side 203, the fourth side 204, the fifth side 205, the sixth side 206, the seventh side 207, the eighth side 208.

[0086] The first side 201, the second side 202, the seventh side 207, and the eighth side 208 constitute the second support unit 216 and the second cavity formed in the second support unit 216. The third side 203, the fourth side 204, the fifth side 205, and the sixth side 206 together constitute the first support unit 215, and together constitute a first cavity for...

Embodiment 3

[0097] See Figure 12 to 15 Embodiment 3 of the present invention, the first embodiment of the present invention, the second embodiment, which is divided into embodiment 2, and the buckle plate 2 is continuously bent-forming three fold line type support 21 and the support of the supported line type support 21 and the support. Three cavities formed inside the body 21, including the first support unit 221, the second support unit 222, the third support unit 223, and the first cavity 231, the second cavity 232, the third cavity 233, except for the The support body 21 of the next layer of the buckle plate 2 is nested in each cavity of the first cavity.

[0098] In the present embodiment, each adjacent two second support units and adjacent two third support units include a support gap, when the locking plate 1 is connected to the buckle plate 2, Each adjacent two second support unit 222 is formed in a horizontal direction, and the outer wall of the two third support units 223 is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com