Infrared welded liftgate assembly and process of making same

A technology for lifting doors and components, which is applied to doors, household components, vehicle components, etc., can solve the problems of increasing processing steps, and achieve the effects of weight reduction, good performance, and improved cross-sectional characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

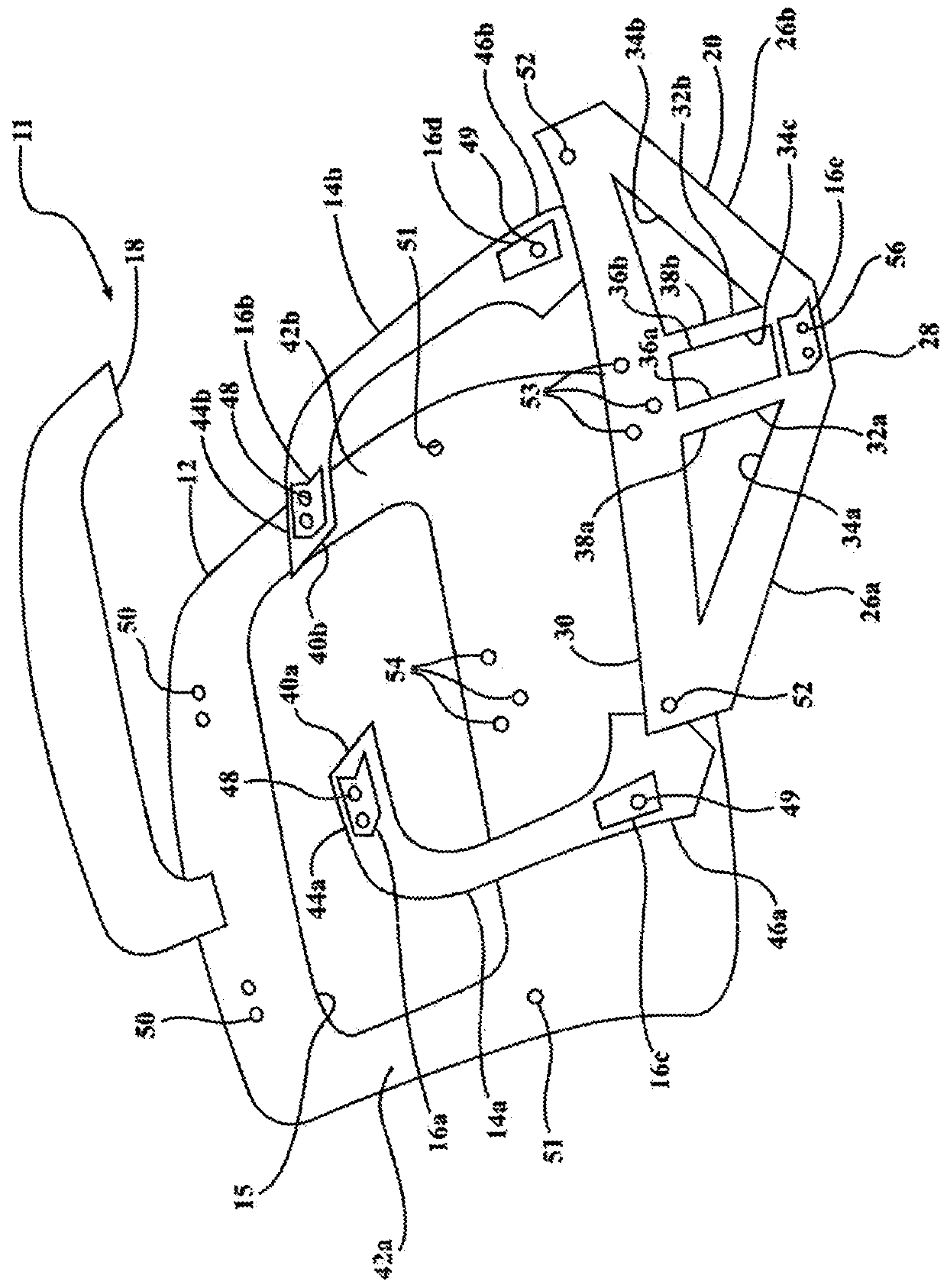

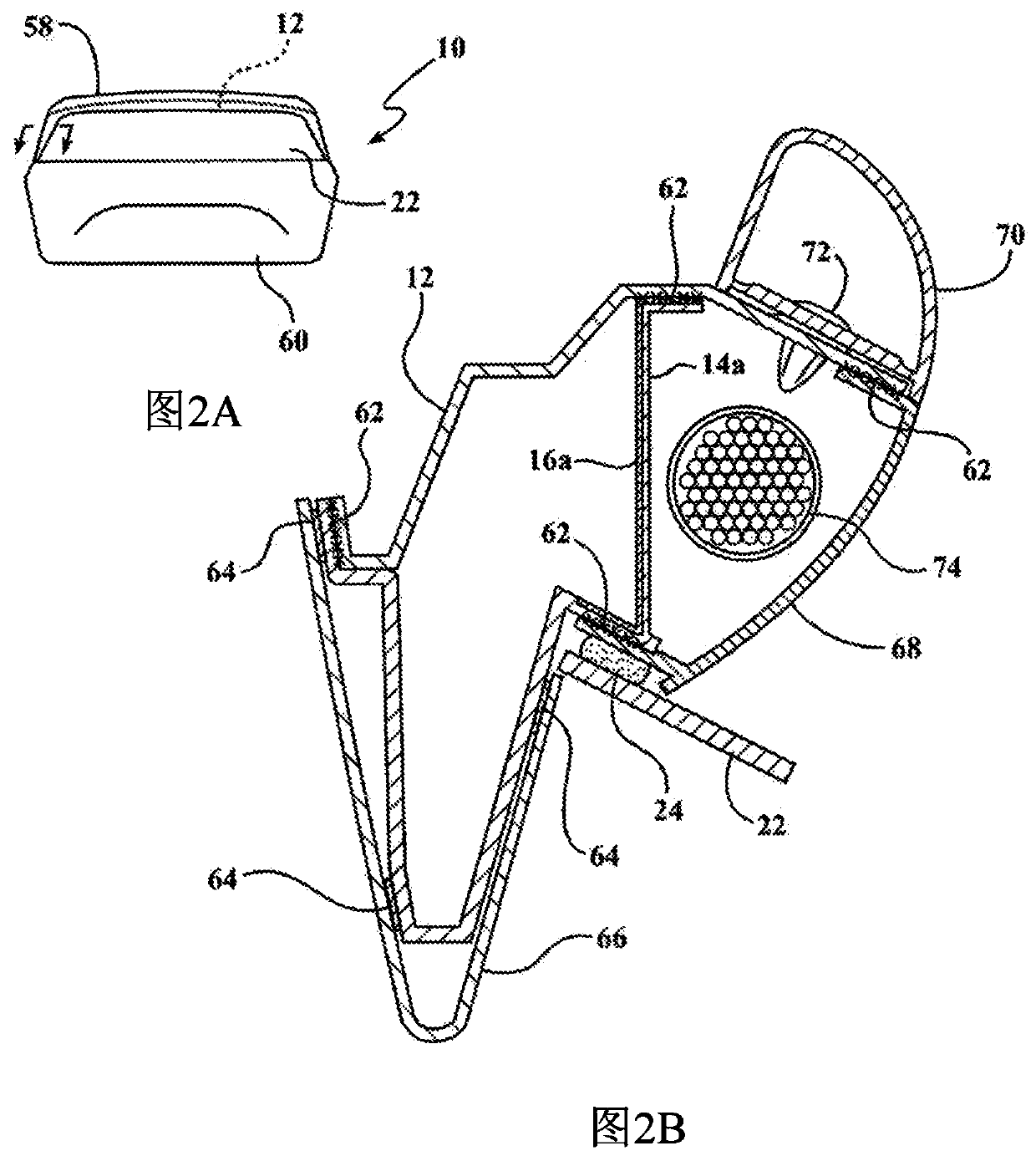

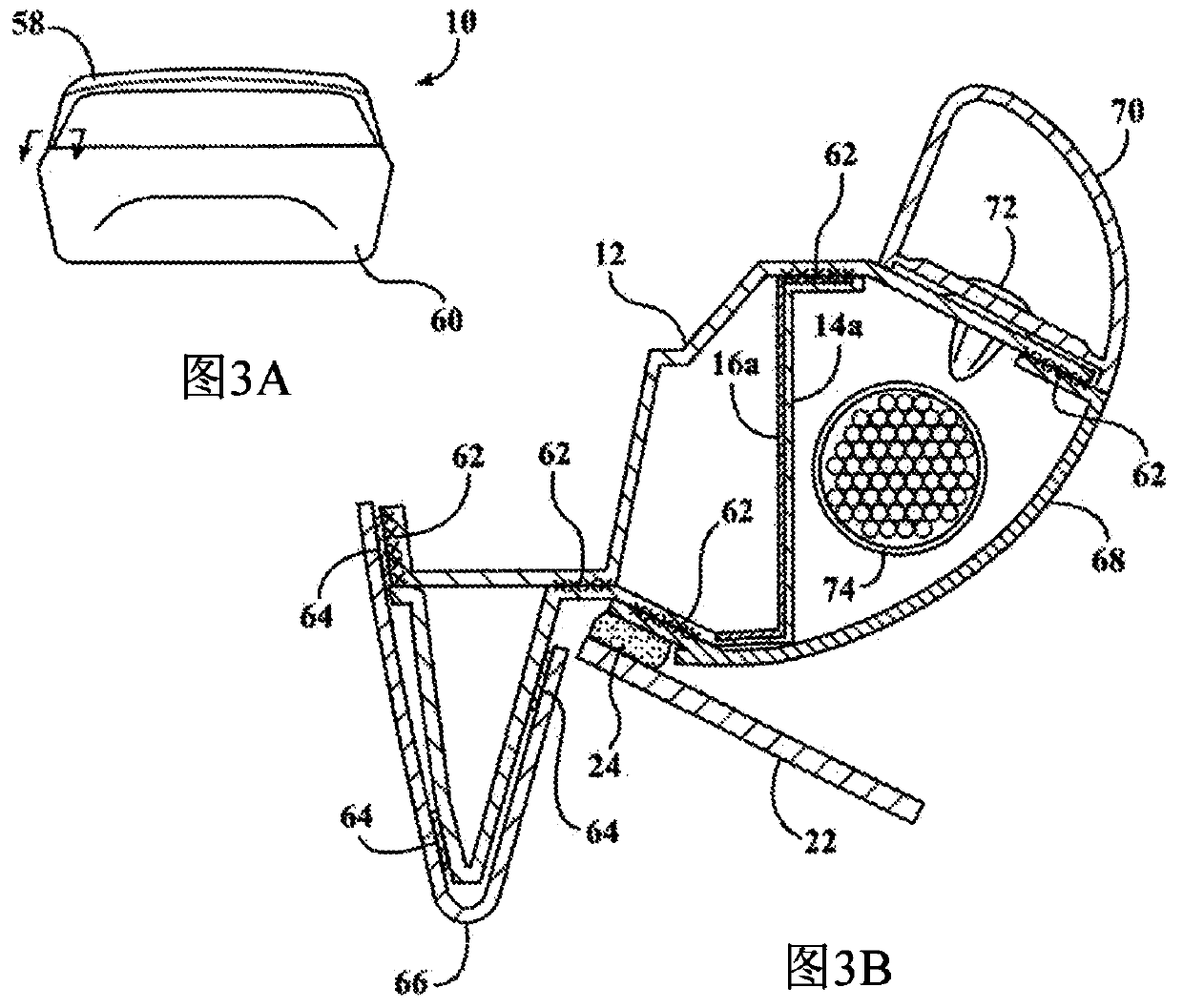

[0033] The following description of preferred embodiments is merely exemplary in nature and is in no way intended to limit the invention and its application or uses.

[0034] Referring generally to the drawings, the present invention generally provides an assembly comprising at least one localized reinforcement attached to at least one reinforcement, wherein infrared welding of the at least one reinforcement to at least one panels combined. The at least one panel is attachable to at least one other panel, preferably the at least one other panel comprises a Class A surface. The invention also typically provides a combination of local reinforcement to reinforcement overmoulding and infrared welding of the components. This application relates to components and methods of making the same.

[0035]Although a liftgate assembly is depicted throughout the drawings and described herein, it should be understood that an exterior body panel assembly that is any type of vehicle component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com