Environment-friendly prefabricated fast-assembly lattice beam and construction method

A green and environmentally friendly lattice beam technology, applied in infrastructure engineering, excavation, cultivation, etc., can solve the problems of non-biodegradable concrete lattice, inability to integrate slope soil, long concrete pouring time, etc., to save Reduce manpower and engineering maintenance costs and achieve ecological and environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

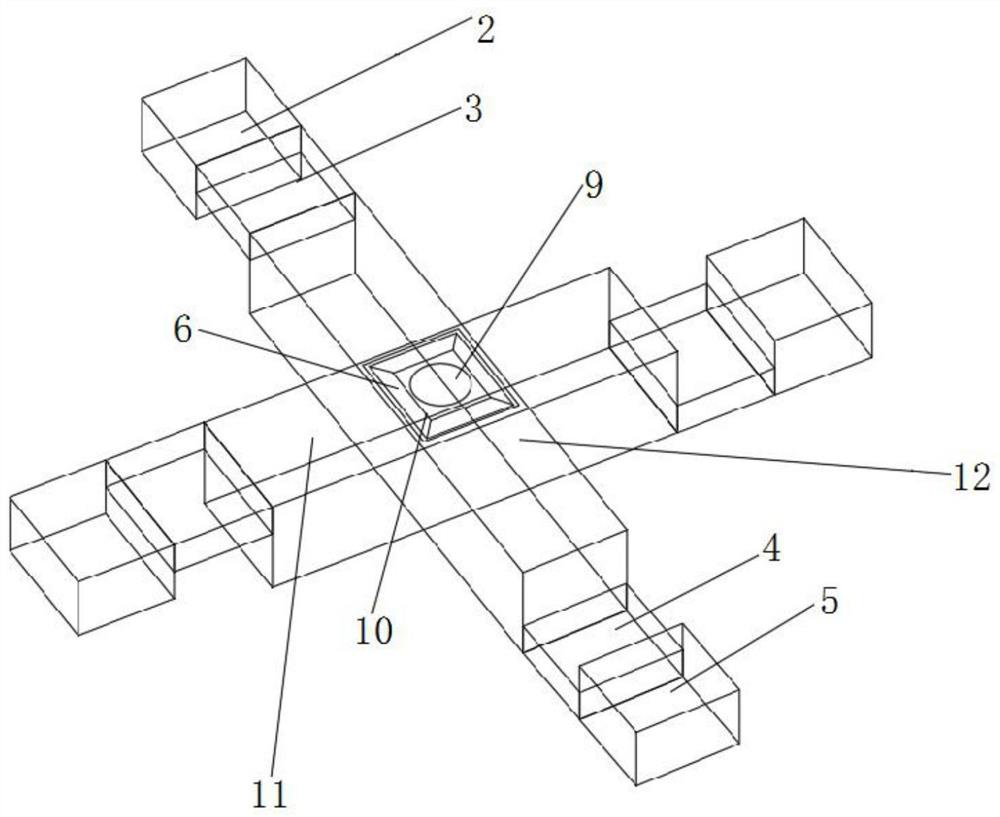

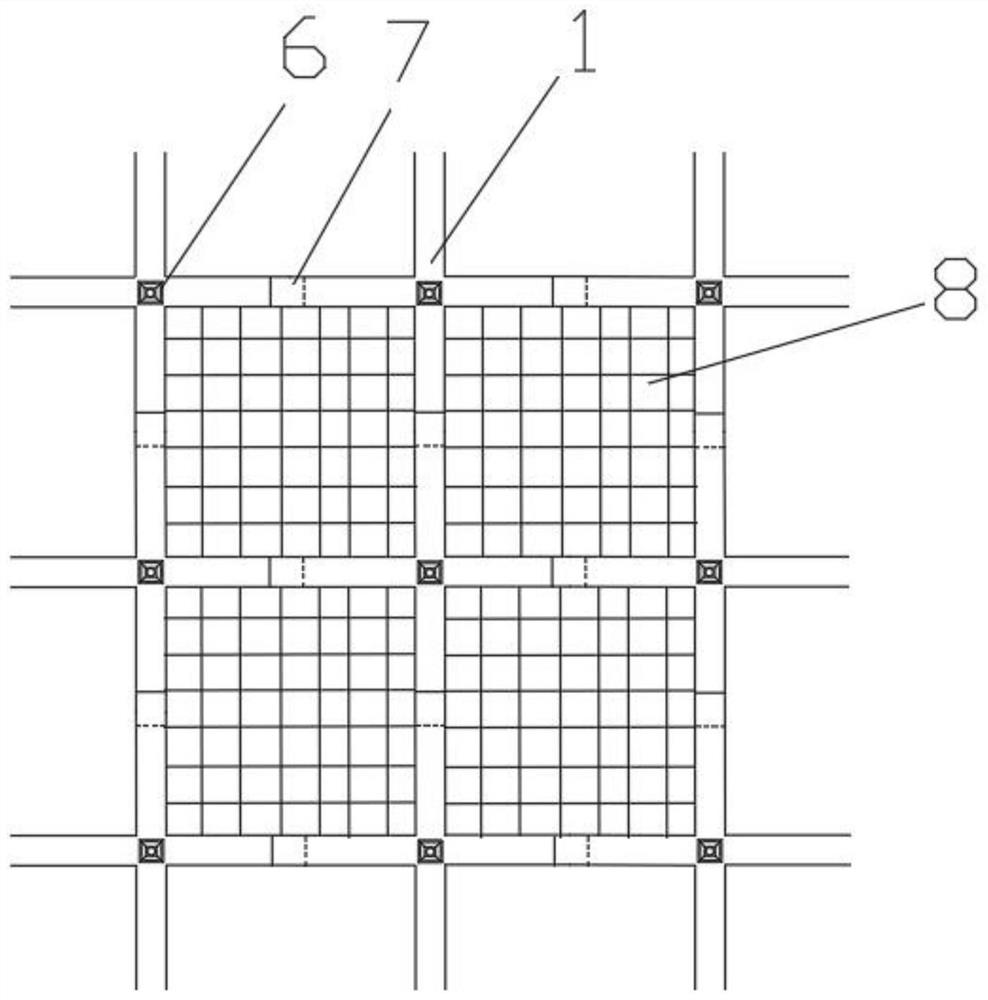

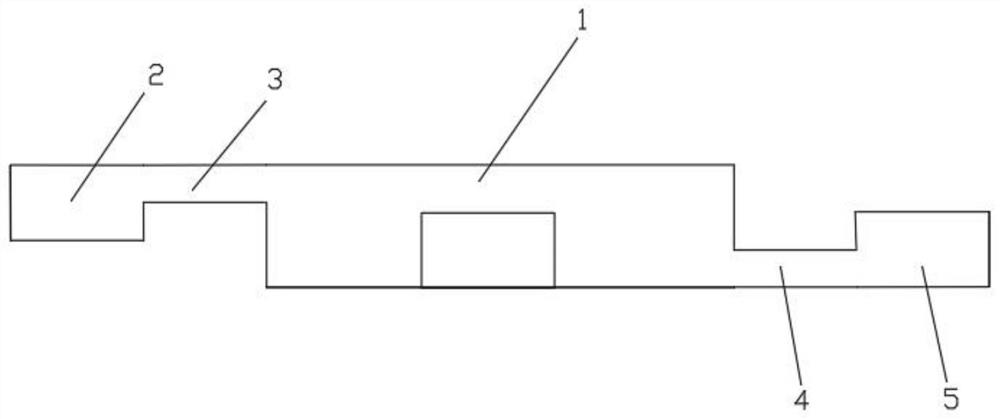

[0029] Such as Figure 1-5 As shown, this embodiment provides a green environmental protection prefabricated quick-install lattice beam, including a lattice beam body, and the lattice beam body is grid-shaped and formed by arranging and connecting several cross-shaped beam bodies; each cross-shaped The beams are all reinforced concrete structures, and the intersection of the beam and the center of the vertical beam of the cross-shaped beam is provided with a concrete groove for accommodating the anchor head, and a backing plate is arranged in the concrete groove, and the backing plate and the concrete groove are set There are corresponding anchor holes, and an ecological geotechnical bag is placed in the grid of the lattice beam body. One side of the crossbeam and the vertical beam of the cross-shaped beam body is provided with a downward boss a and a groove a, and the other side is provided with an upward boss b and a groove b, and the groove a, the groove Groove b is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com