Upright post collecting and releasing type pallet structure

A retractable and upright column technology, which is applied in the field of column retractable pallet structure, can solve the problems of increasing transportation costs, increasing storage space, time-consuming and laborious, etc., and achieves the effects of saving costs, improving carrying capacity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

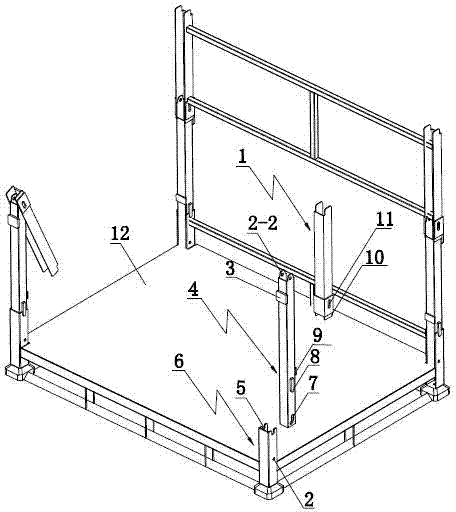

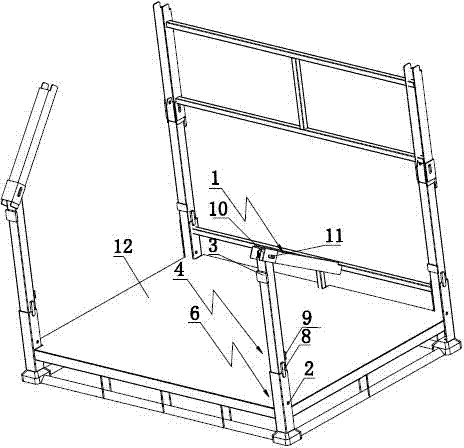

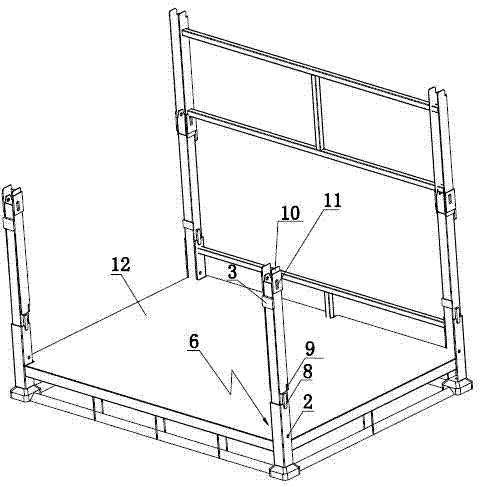

[0015] See figure 1 , The column retractable tray structure of the present invention is a frame structure, and the fixed column and some movable columns are all made of C-shaped steel material, which has the advantages of thin wall, light weight, excellent cross-sectional performance, and high strength. Four fixed uprights 6 parallel to each other and perpendicular to each other are arranged on four corners of the tray surface, a circular hole 2 is arranged in the middle of the fixed uprights 6 , and a U-shaped card slot 5 is arranged on the top of the fixed uprights 6 . The bottom of the second movable column 4 is provided with a special-shaped long hole 7, so that there is a certain space for movement when the column with pin shaft is overturned, and a fixed block 8 is arranged above the special-shaped long hole 7, and the special-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com