Production method of lithium non-expansion heat-resistant ceramic

A production method and heat-resistant technology, applied in applications, household appliances, clay products, etc., can solve the problems of lithium content not exceeding 3%, narrow firing range of lithium ceramics, and inability to engage in ceramic production, and achieve heat resistance. The effect of good shock resistance, light weight and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below by embodiment the present invention is further described:

[0024] Composition process of industrial lithium salt synthesis of lithium non-expansion heat-resistant ceramics:

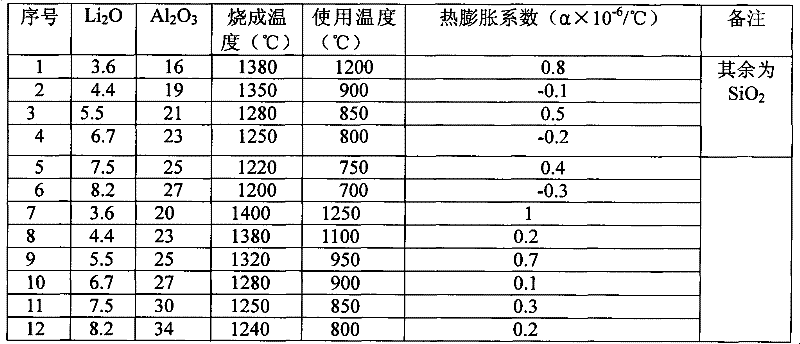

[0025] 1. Composition

[0026] 1. Main chemical composition: Li 2 O, Al 2 o 3 and SiO 2 .

[0027] 2. The weight composition range of the main chemical components

[0028] a. Li 2 O content 3.0-8.5%;

[0029] b.Al 2 o 3 Content 13-25%;

[0030] c. The remaining content is SiO 2 ;

[0031] d. According to different requirements, a small amount of ZrO, NiO, ZnO, SiC, Co can also be introduced 3 o 4 , CuO, Fe 2 o 3 , rare earth oxides and nanomaterials of these substances, etc., adjust their chemical resistance, high temperature resistance, thermal conductivity and color.

[0032] 2. Process

[0033] 1. Pre-synthesis of lithium-containing raw materials (taking lithium carbonate as an example)

[0034] a. Pre-synthesized raw materials do not have high requirements on the ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com