Production device of building decoration part and preparation process of building decoration part

A technology for building decoration and production equipment, applied in the direction of manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of high production cost, hidden dangers of construction safety, non-standard workshop products, etc., to reduce the cost of molds, water and electricity costs. Low, high appearance value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in conjunction with the accompanying drawings.

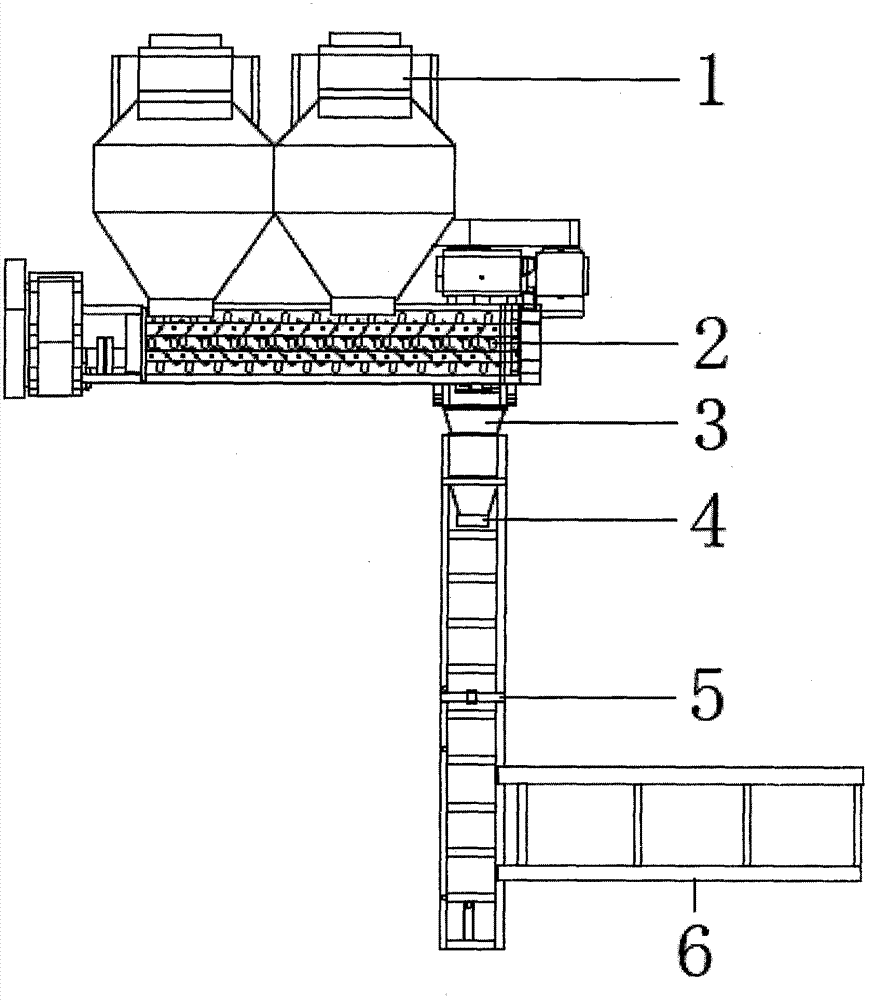

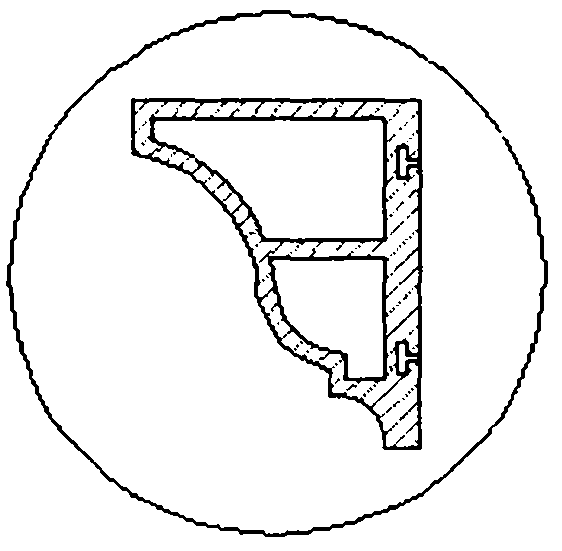

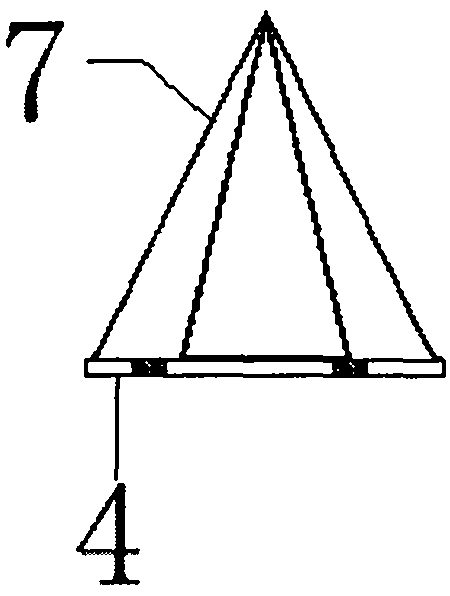

[0022] Such as figure 1 , the production equipment of a kind of building decoration member of the present invention, comprises dry powder mixer 1, wet slurry premixer 2 and extruder 3, and extruder 3 is high-pressure vacuum twin-screw concrete extruder, and the outlet of extruder 3 A mold 4 is provided, and the mold 4 is a computer-cut standard steel mold. The mold 4 is provided with a mold mouth, and the slurry in the extruder 3 is extruded through the mold mouth, and the product is formed on the cross-section of the mold mouth. The cost of the mold 4 is greatly reduced by laying a large-area mold body; the surface of the building components formed by the mold mouth is very smooth, without errors, without rough surfaces, high appearance value, thin-walled building components, light weight, and standardized edges and corners. Such as figure 2 As shown, the cross-section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com