Flexibility pulping process of reconstituted tobaccos

A technology of reconstituted tobacco leaves and flexibility, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low pulp yield, poor pulp quality stability, large fluctuation of product physical indicators, etc. The effect of yield submission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

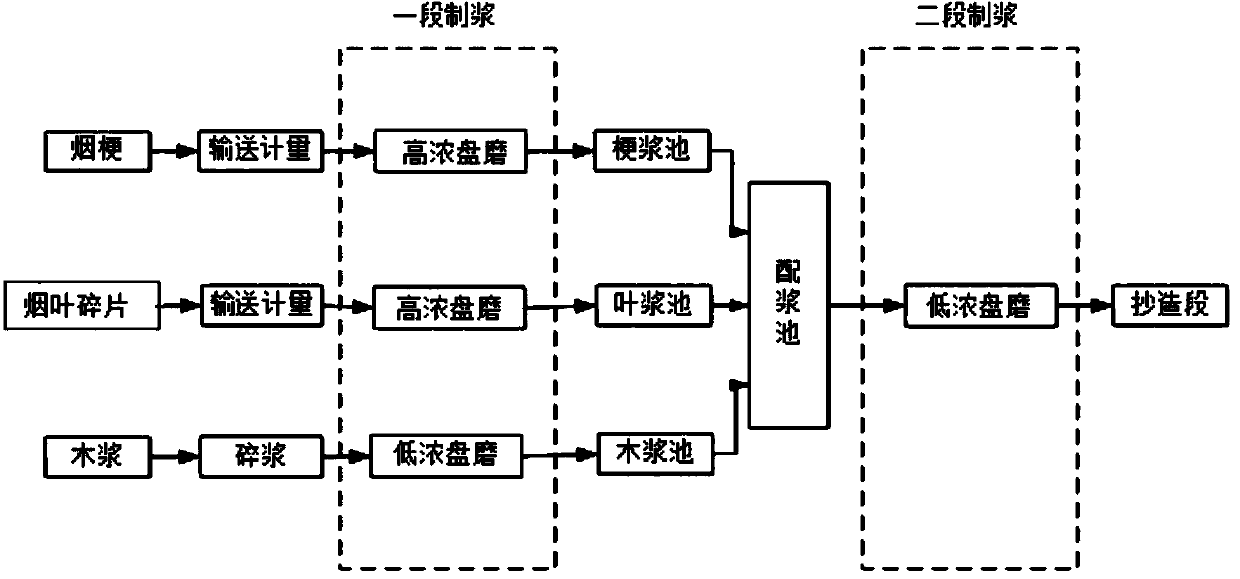

[0020] A flexible pulping process for reconstituted tobacco leaves, the method steps are as follows:

[0021] ① Use a high-concentration disc mill to beat the solid material of the extracted tobacco leaf fragments in series. Adjust the concentration to 3.0% in the line pulp storage tank; use two high-consistency disc mills in series to beat the extracted tobacco stem solid material, the flow rate is 500kg / h based on absolute dry pulp, the beating concentration is 15%, and the beating degree is 15°SR , the obtained stalk pulp slurry enters the stalk line pulp storage tank to adjust the concentration to 3.5%; after the wood pulp is crushed, the concentration is adjusted to 3.0%, and a low-consistency double-disc mill is used for beating, with a flow rate of 10m 3 / h, the degree of beating is 15°SR, and the treated wood pulp enters the wood pulp storage tank;

[0022] ② After the leaf pulp, stem pulp and wood pulp after a period of beating treatment in step ① are mixed according...

Embodiment 2

[0026] A flexible pulping process for reconstituted tobacco leaves, the method steps are as follows:

[0027] ①Three sets of high-concentration disk mills are used to beat the solid material of the extracted tobacco leaf fragments in series. Adjust the concentration to 4.5% in the line pulp storage tank; use 4 sets of high-concentration disc mills in series to beat the extracted tobacco stem solid material, the flow rate is 3000kg / h based on absolute dry pulp, the beating concentration is 8%, and the beating degree is 16°SR , the obtained stalk pulp slurry enters the stalk line pulp storage tank to adjust the concentration to 4.0%; after the wood pulp is crushed, the concentration is adjusted to 2.5%, and two low-consistency double-disc mills are used for beating in series, with a flow rate of 30m 3 / h, the degree of beating is 12°SR, and the treated wood pulp enters the wood pulp storage tank;

[0028] ②The leaf pulp, stalk pulp and wood pulp after a period of beating treatm...

Embodiment 3

[0032] A flexible pulping process for reconstituted tobacco leaves, the method steps are as follows:

[0033] ①Use two high-concentration disk mills to beat the solid material of the extracted tobacco leaf fragments in series. Adjust the concentration to 3.5% in the line pulp storage tank; use three high-consistency disc mills in series to beat the extracted tobacco stem solid material, the flow rate is 1500kg / h based on absolute dry pulp, the beating concentration is 20%, and the beating degree is 30°SR , the obtained stalk pulp slurry enters the stalk line pulp storage tank to adjust the concentration to 4.5%; after the wood pulp is crushed, the concentration is adjusted to 3.0%, and a low-consistency disc mill is used for beating, with a flow rate of 5m 3 / h, the degree of beating is 12°SR, and the treated wood pulp enters the wood pulp storage tank;

[0034] ②The leaf pulp, stalk pulp and wood pulp after a period of beating treatment in step ① are sent to the distribution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com