Tobacco stem treatment method for improving papermaking method remanufactured tobacco leaf quality

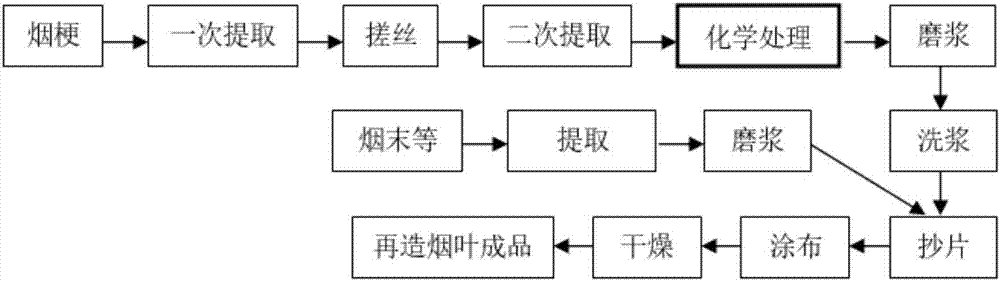

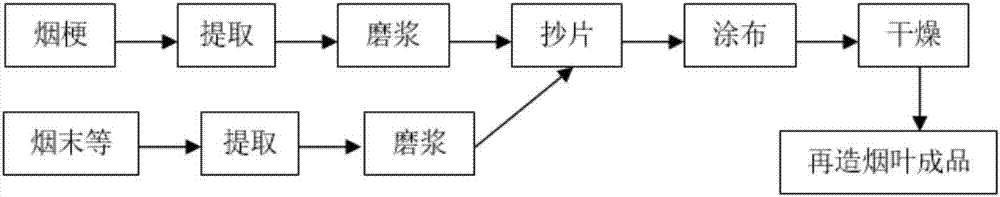

A technology for reconstituted tobacco leaves and a treatment method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of weak removal effect of lignin and pectin, reduced quality improvement of reconstituted tobacco leaves, loss of useful substances in tobacco, etc. The effect of reducing the energy consumption of beating and reducing the loss of tobacco components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

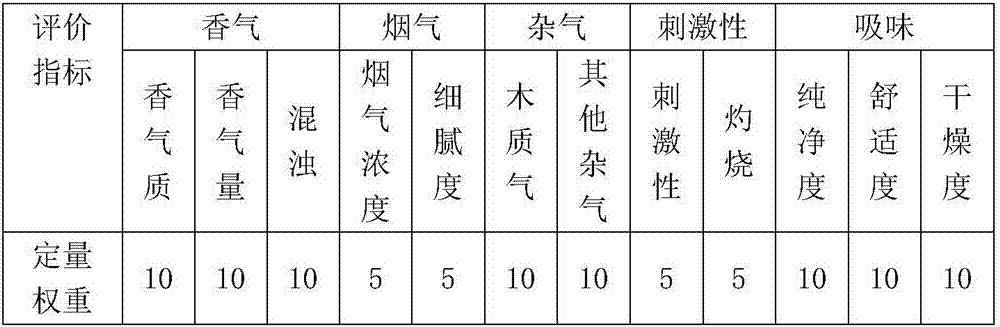

Examples

Embodiment 1

[0020] A kind of tobacco stem processing method that the present invention proposes to improve the quality of papermaking reconstituted tobacco leaves comprises the following steps:

[0021] S1, the first extraction of tobacco stems: put the tobacco stems into a shredder, cut them to a length of 4 cm, wash and remove the sand to obtain pretreated tobacco stems, and combine the pretreated tobacco stems with water according to the solid-liquid ratio of 1:7 Add it into a stirring extraction tank, stir and extract at a high temperature of 80°C for 40 minutes, and then squeeze it to a moisture content of 30% through a squeeze dryer to obtain tobacco stem A;

[0022] S2, thread rolling treatment: the tobacco stem A obtained in step S1 is sent to a thread rolling machine for thread rolling treatment to obtain tobacco stem B;

[0023] S3, the second extraction of tobacco stems: according to the solid-to-liquid ratio of 1:7, add the tobacco stems B and water obtained in step S2 into th...

Embodiment 2

[0048] A kind of tobacco stem processing method that the present invention proposes to improve the quality of papermaking reconstituted tobacco leaves comprises the following steps:

[0049] S1, the first extraction of tobacco stems: Put the tobacco stems into the shredder, cut them to a length of 3 cm, wash and remove the sand to obtain pretreated tobacco stems, and mix the pretreated tobacco stems with water according to the solid-liquid ratio of 1:6. Add it into a stirring extraction tank, stir and extract at a high temperature of 72°C for 35 minutes, and then squeeze it to a moisture content of 22% through a squeeze dryer to obtain tobacco stem A;

[0050] S2, thread rolling treatment: the tobacco stem A obtained in step S1 is sent to a thread rolling machine for thread rolling treatment to obtain tobacco stem B;

[0051] S3, the second extraction of tobacco stems: According to the solid-liquid ratio of 1:6, add the tobacco stems B and water obtained in step S2 into the st...

Embodiment 3

[0068] A kind of tobacco stem processing method that the present invention proposes to improve the quality of papermaking reconstituted tobacco leaves comprises the following steps:

[0069] S1, the first extraction of tobacco stems: put the tobacco stems into a shredder, cut to a length of 3.4 cm, wash and remove sand to obtain pretreated tobacco stems, and mix the pretreated tobacco stems with water according to the solid-to-liquid ratio of 1:6.6 Add them together into a stirring extraction tank, stir and extract at a high temperature of 77°C for 38 minutes, and then squeeze them to a moisture content of 26% through a squeeze dryer to obtain tobacco stem A;

[0070] S2, thread rolling treatment: the tobacco stem A obtained in step S1 is sent to a thread rolling machine for thread rolling treatment to obtain tobacco stem B;

[0071] S3, the second extraction of tobacco stems: according to the solid-to-liquid ratio of 1:6.6, add the tobacco stems B obtained in step S2 and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com