Breathable medical adhesive tape base material and manufacturing method thereof

A manufacturing method and substrate technology, applied in papermaking, textiles and papermaking, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve problems such as poor evenness, fiber floating, poor paper strength, and poor flexibility , to achieve the effect of high ratio, flexibility, easy to tear, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) 60% coniferous wood pulp is subjected to moderate beating treatment, and the pulp density is increased by 5 O SR, mixed with 38% polyester fiber and 2% water-soluble fiber after treatment, added 0.5% wet strength agent by fiber weight to the mixed fiber; fully stirred. Among them, the proportion of 1.0dtex×3mm polyester fiber is 28%, and the proportion of 1.5dtex×12mm polyester fiber is 10%.

[0024] (2) The mixed fibers are made by inclined wire paper machine, and strengthened by surface sizing. The surface glue is a mixture of 2% PVA (polyvinyl alcohol) and 1% AKD, and the coating amount is 1 g / ㎡, coiled into finished products after drying.

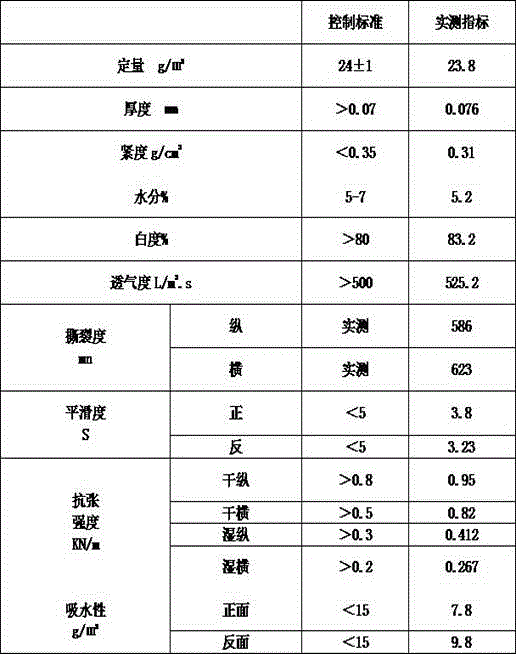

[0025] The indicators of breathable medical tape base material are as follows:

[0026]

Embodiment 2

[0028] (1) 60% coniferous wood pulp is subjected to moderate beating treatment, and the pulp density is increased by 5 O SR, mixed with 38% polyester fiber and 2% water-soluble fiber after treatment, added 0.5% wet strength agent and 1% AKD to the mixed fiber; fully stirred. Among them, the proportion of 1.0dtex×3mm polyester fiber is 33%, and that of 1.5dtex×12mm polyester fiber is 5%.

[0029] (2) The mixed fibers are made by a cylinder paper machine, and the surface sizing is carried out to strengthen the treatment. The surface glue is a mixture of 2% PVA (polyvinyl alcohol) and 1% AKD, and the coating amount is 1.5g / ㎡, coiled into finished products after drying.

[0030] The difference from Example 1 is that the rotary screen is used instead of the inclined screen for copying. Appropriately increase the proportion of polyester staple fiber.

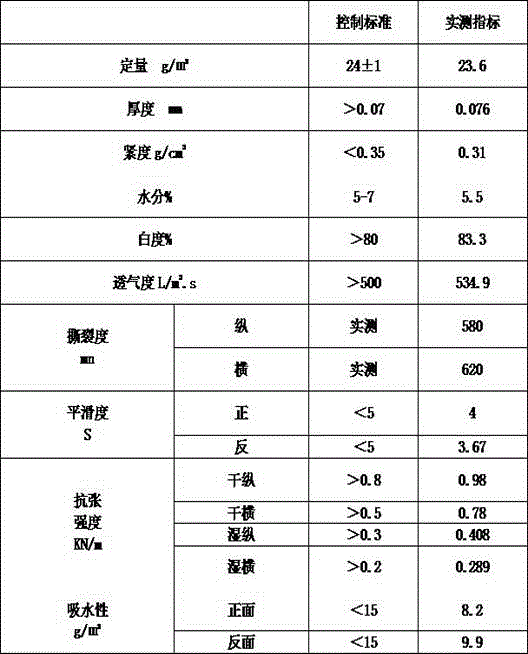

[0031] The indicators of breathable medical tape base material are as follows:

[0032]

Embodiment 3

[0034] The difference from Example 1 is that (1) 65% softwood pulp is subjected to moderate beating treatment, and the degree of pulp is increased by 4 O SR, mixed with 33% polyester fiber and 2% water-soluble fiber after treatment, added 0.5% wet strength agent to the mixed fiber; fully stirred. Among them, the proportion of 1.5dtex×3mm polyester fiber is 26%, and 1.5dtex×12mm polyester fiber accounts for 7%.

[0035] (2) The mixed fibers are made by a cylinder paper machine, and the surface sizing is carried out to strengthen the treatment. The surface glue is a mixture of 2% PVA (polyvinyl alcohol) and 1% AKD, and the coating amount is 1.0g / ㎡, coiled into finished products after drying.

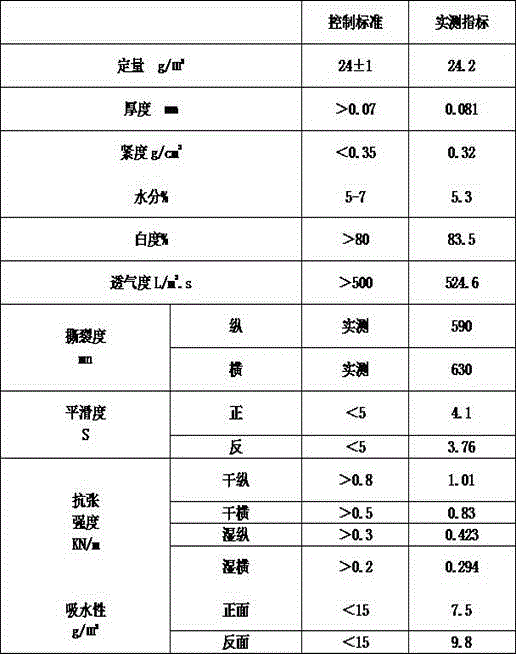

[0036] The indicators of breathable medical tape base material are as follows:

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com