Functional active probiotic soybean milk and preparation method thereof

An active probiotic and functional technology, applied in the field of functional active probiotic soymilk and its preparation, can solve problems such as reducing the absorption rate of nutrients, and achieve good product stability, good texture and flavor, and broad market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

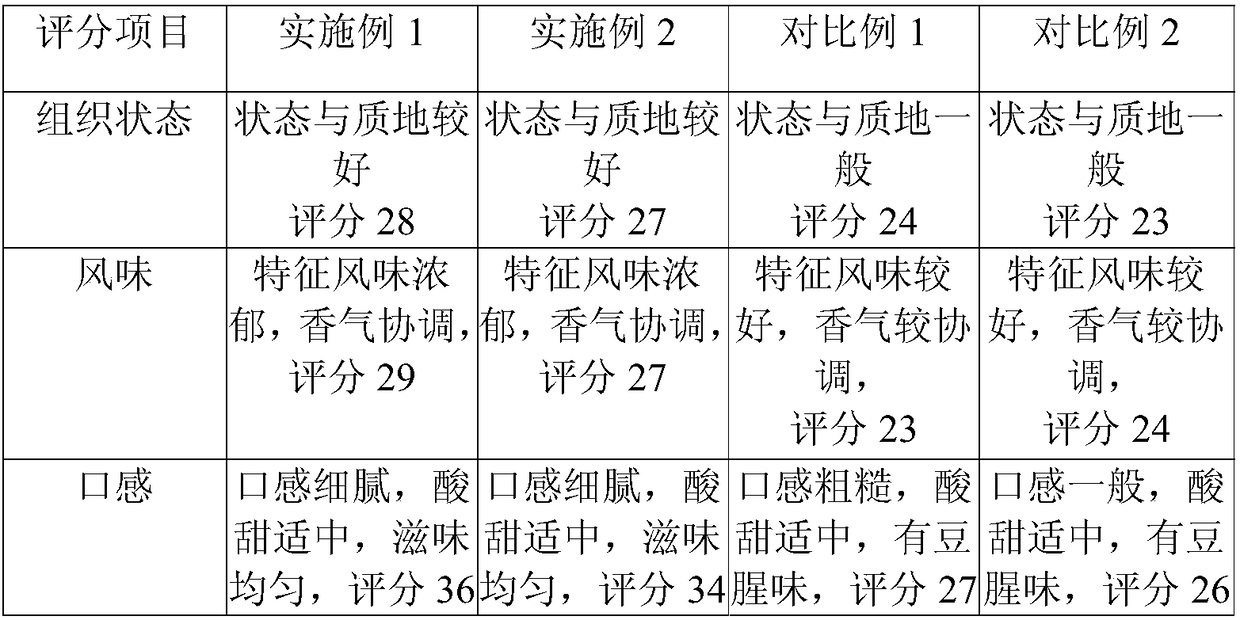

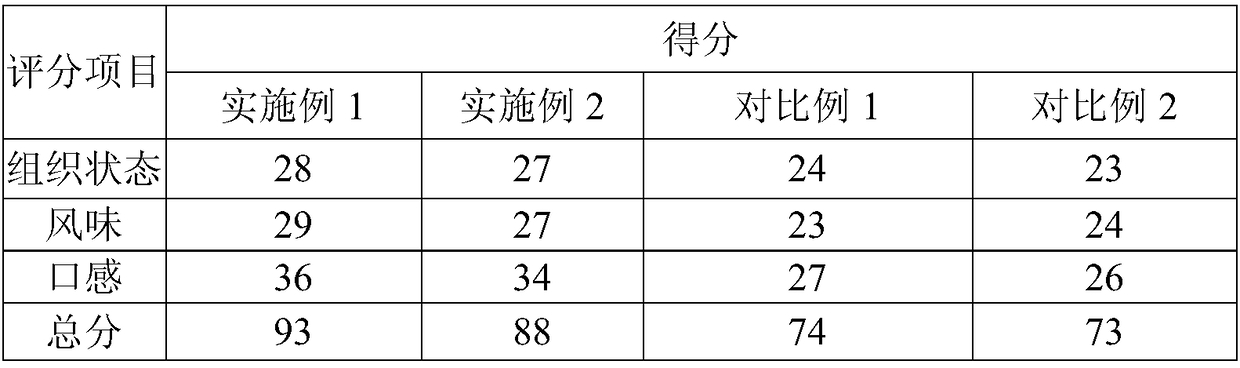

Embodiment 1

[0053] This example provides a preparation of functional active probiotic soymilk, which is prepared by fermentation with the following components as raw materials:

[0054] Based on the total weight of raw materials as 1000g, it includes 907g of soy milk, 70g of white sugar, 20g of coconut oil, stabilizer (2.5g of acetylated distarch adipate, 0.5g of pectin), 100U / T of starter (SYAB1:0.1 U).

[0055] 1. The preparation of the soymilk raw material: select complete soybeans with plump and uniform grains and no moth-eaten and mildew. The optimum conditions for soybean germination: place soybeans at 27°C with a mass concentration of sodium glutamate of 4.0 mg / L, vitamin B6 Soak in an aqueous solution with a molar concentration of 3mol / L for 19 hours, wash with pure water, blanch, grind with hot water at 80°C, the mass ratio of soybeans to water is 1:8, and finally ultrasonically treat the coarsely ground germ soybean slurry. With a power of 150W and an ultrasonic time of 30 minu...

Embodiment 2

[0077] This example provides a preparation of functional active probiotic soymilk, which is prepared by fermentation with the following components as raw materials:

[0078] Based on the total weight of raw materials as 1000g, it includes 910g of soybean milk, 70g of white sugar, 15g of coconut oil, stabilizer (3g of acetylated distarch adipate, 0.5g of agar, 1.5g of whey protein), and 100U / T of starter (SYAB1:0.1U).

[0079] 1. The preparation of the soymilk raw material: select intact soybeans with plump and uniform grains and no moth-eaten and mildew, and the optimum conditions for soybean germination: at 27°C, place the soybeans at a concentration of 4.0 mg / L sodium glutamate, and vitamin B6 in an aqueous solution with a molar concentration of 3 mol / L for 19 hours, washed with pure water, blanched, refined with hot water at 80°C, the mass ratio of soybean water to 1:8, and passed through a 200-mesh sieve to make soybean milk for later use;

[0080] Two, the preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com